Circulating cooling structure

A technology of circulating cooling and cooling structure, applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of motor performance degradation, sudden cooling and sudden heating of the shaft, damage to the motor shaft, etc., to reduce the damage Possibility, reducing the effect of damage factors, strengthening the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

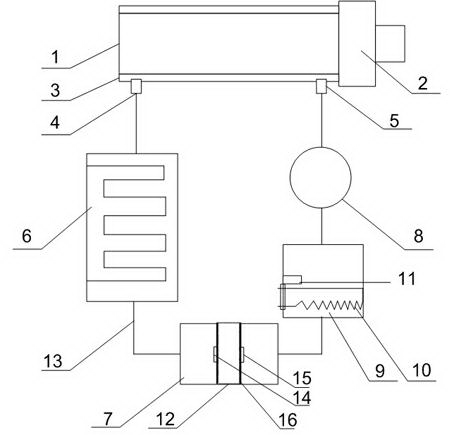

[0020] Such as figure 1 As shown, a circulating cooling structure of the present invention includes a motor main shaft 1, a shaft sleeve 2 is installed outside the motor shaft 1, a spiral groove 3 is arranged on the shaft sleeve 2, and an oil outlet 4 and an oil outlet 4 are opened at the bottom of the spiral groove 3 respectively. An oil inlet 5, a cooling structure and an oil temperature regulating mechanism connected to each other are installed between the oil outlet 4 and the oil inlet 5, and the cooling structure and the oil temperature regulating mechanism are connected to the oil inlet 5, The oil outlet 4 is connected; the cooling structure includes a heat exchanger 6, an oil collection chamber 7 and an oil pump 8, and the heat exchanger 6 is connected with the oil collection chamber 7 and the oil pump 8 through an oil guide pipe 13, and the A filter is also installed in the middle part of the oil chamber 7, and a drain valve can also be installed at the bottom of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com