Electric tracing band for oil well

An electric heating and oil well technology, applied in the direction of heating element shape, etc., can solve the problems of increasing the volume, weight and cost of equipment, reducing the heating efficiency of heating cables, and the weight of copper core iron cables, etc., to improve the electrothermal conversion efficiency and light weight , the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

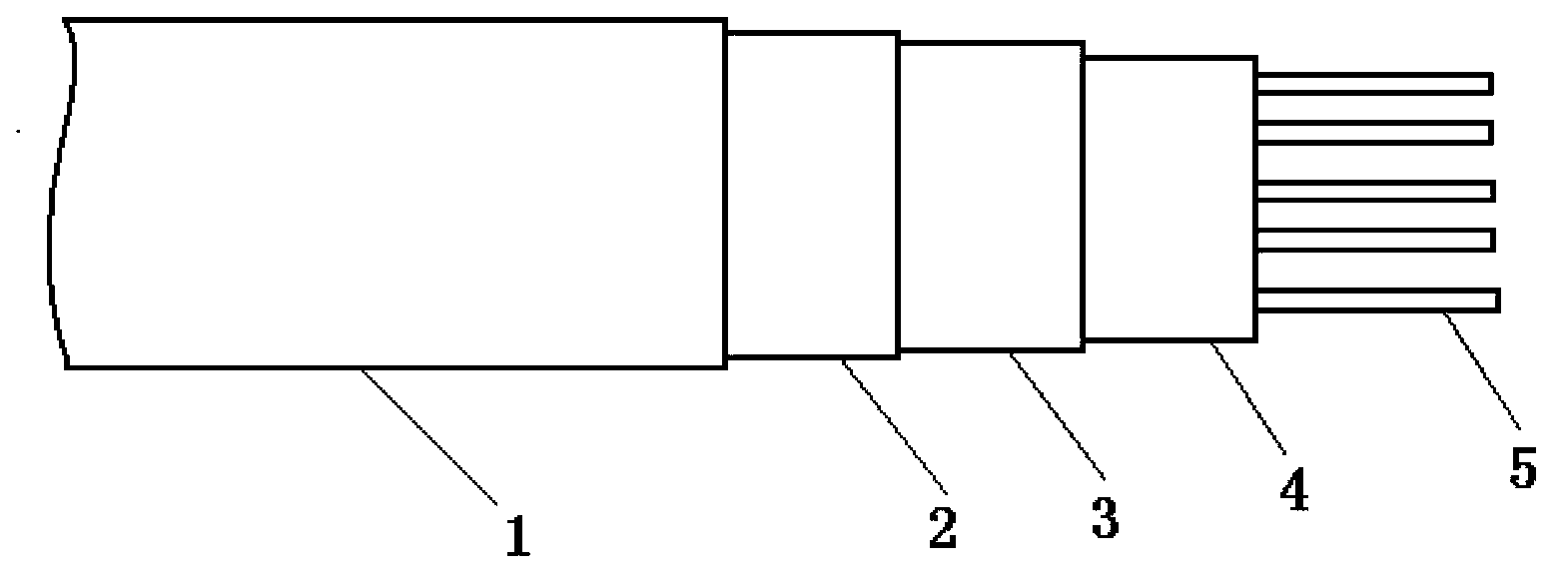

[0024] As shown in Figure 1, an electric heating tape for oil wells, the electric heating tape includes a core tape 4, the core tape 4 is composed of five carbon fiber heating wires 5 arranged in parallel and filled with PTC conductive carbon fiber heating wires 5 It consists of a filler, and the core band 4 is sequentially covered with an insulating layer 3 made of silicone rubber, a shielding layer 2 made of a laminated aluminum foil material, and a protective layer 1.

Embodiment 2

[0026] An electric heating tape for oil wells. The electric heating tape comprises a core tape 4 composed of five carbon fiber heating wires 5 arranged in parallel and a PTC conductive filler filling the carbon fiber heating wires 5. The belt 4 is successively wrapped with an insulating layer 3 made of polyvinyl chloride plastic, a shielding layer 2 made of a laminated copper foil material, and a protective layer 1.

Embodiment 3

[0028] The core tape filler PTC conductive filler of the electric heating tape is composed of polyvinylidene fluoride, magnesium hydroxide, and antioxidant 1010 at 1:4:0.01.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com