Threshing chamber of combined harvester

A combine harvester and threshing machine technology, applied in the threshing room field, can solve the problems of increased assembly error, high maintenance and replacement costs, complex assembly, etc., and achieve the effect of reducing assembly error and making assembly simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

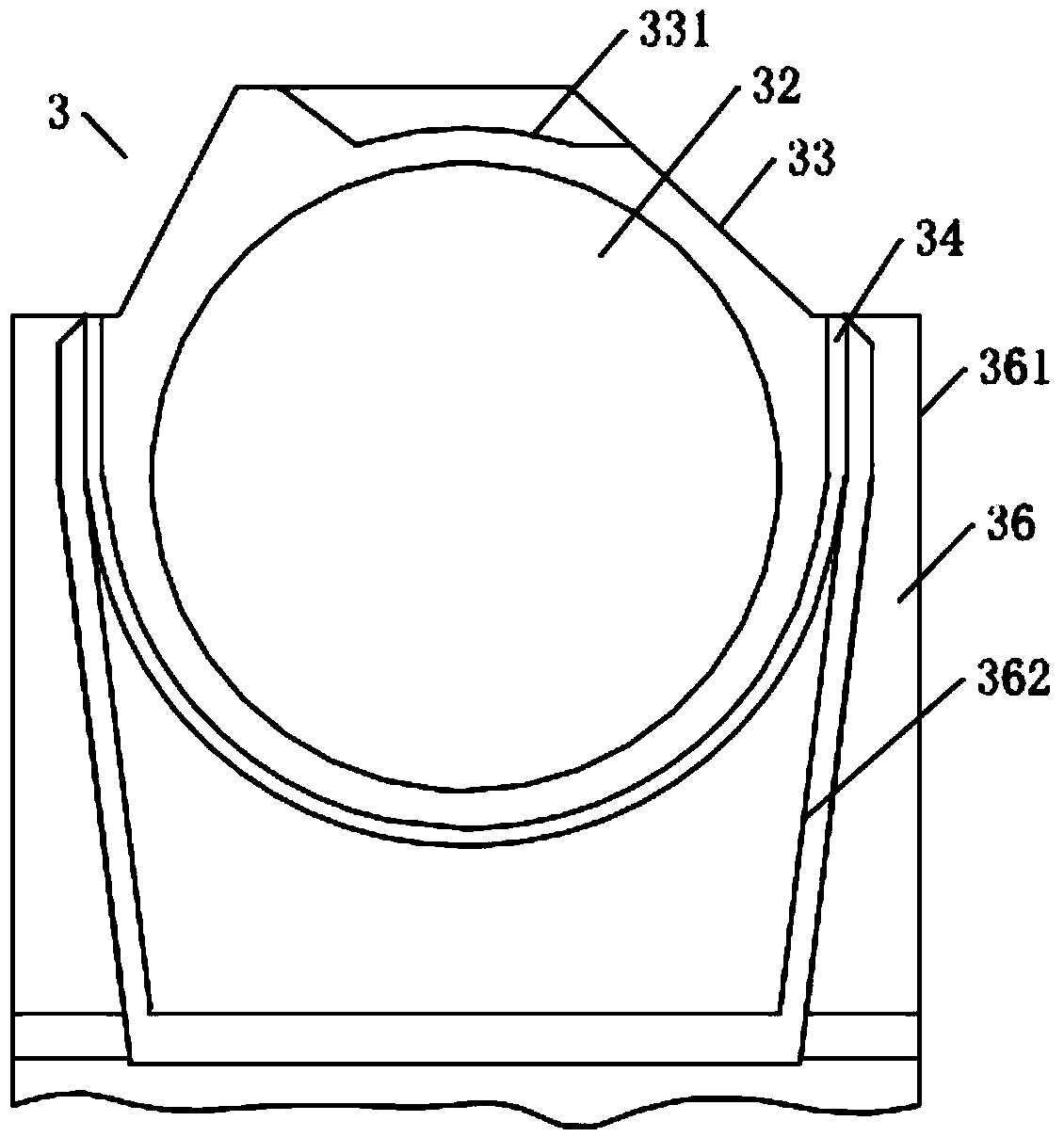

[0016] Threshing Room 3

[0017] Top cover: 33

[0018] Threshing drum: 32

[0019] Separator: 34

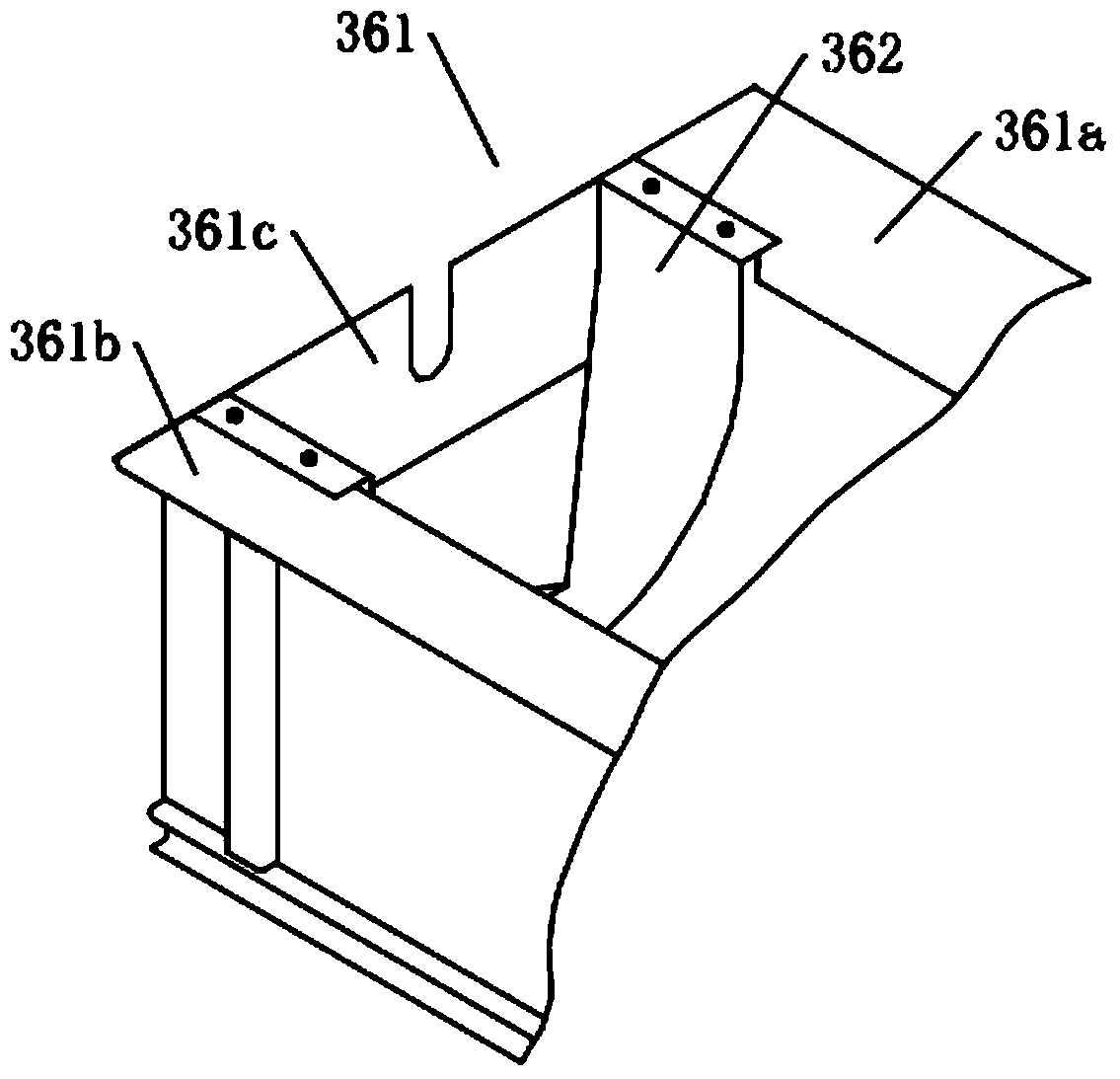

[0020] Thresher Racks: 36

[0021] Upper frame: 361

[0022] Feeding port: 362

[0023] Left wall panel: 361a

[0024] Right wall panel: 361b

[0025] Front wall panel: 361c

[0026] Grass guide board: 331

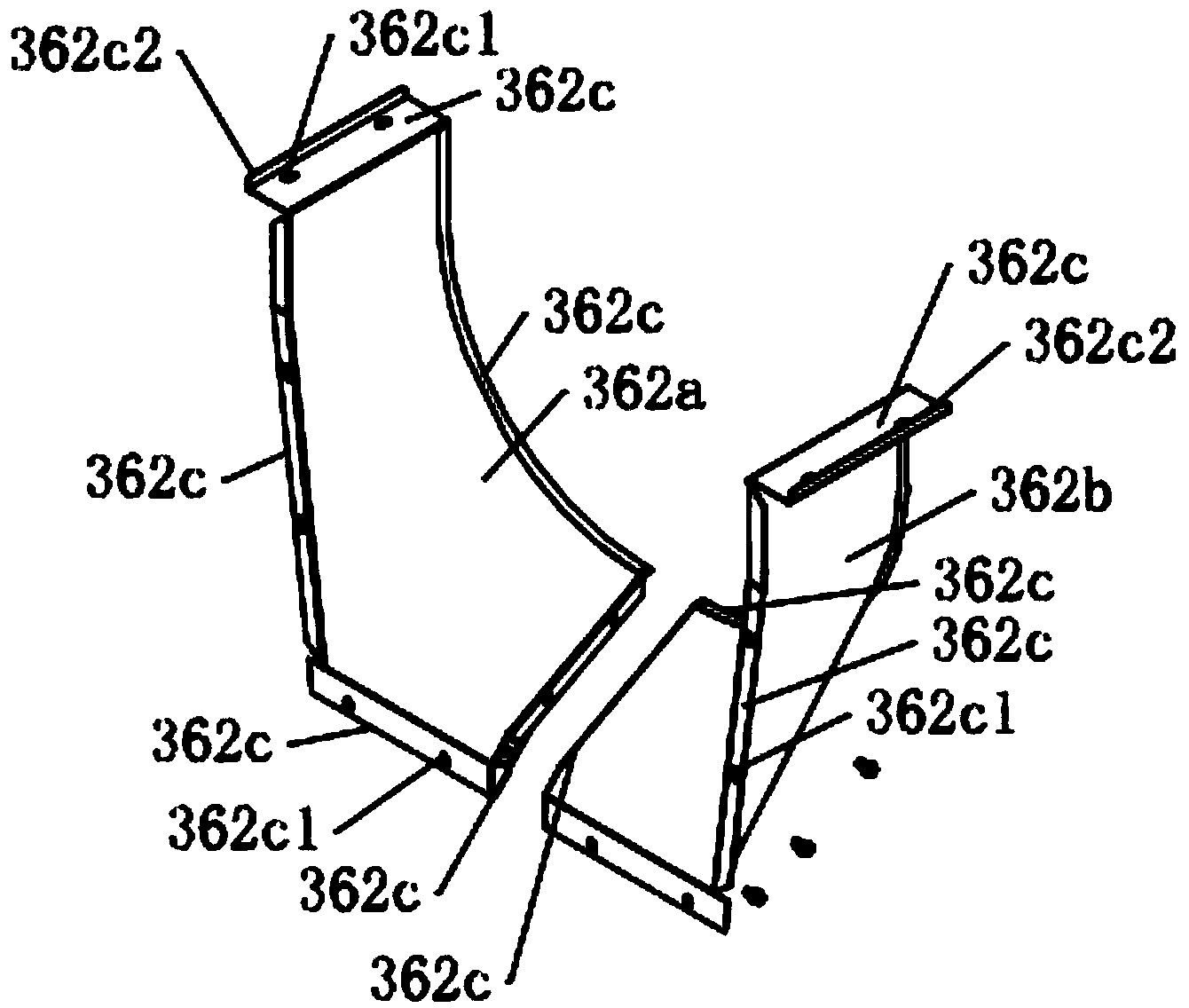

[0027] Right half feeding port: 362a

[0028] Left half feeding port: 362b

[0029] A flange part: 362c

[0030] Mounting hole: 362c1

[0031] Limiting part: 362c2

[0032] Left side wall 363a

[0033] Right side wall 363b

[0034] Bottom wall 363d

[0035] Limiting part 363c2

[0036] See attached Figure 1-4 According to the threshing chamber 3 of the combine harvester of the present invention, it is composed of a top cover 33, a threshing drum 32, a separating screen 34, a threshing rack frame 36, and the like. The threshing frame 36 is made up of upper frame 361 and feeding port 362 etc. The upper frame 361 includes a left wall panel 361a, a right wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com