Pipe bar cutoff machine

A cutting machine and pipe rod technology, applied in the field of pipe rod processing, can solve the problems of low cutting precision, large force, large processing deformation, etc., and achieve the effect of small deformation, smooth cutting surface and not easy to deform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

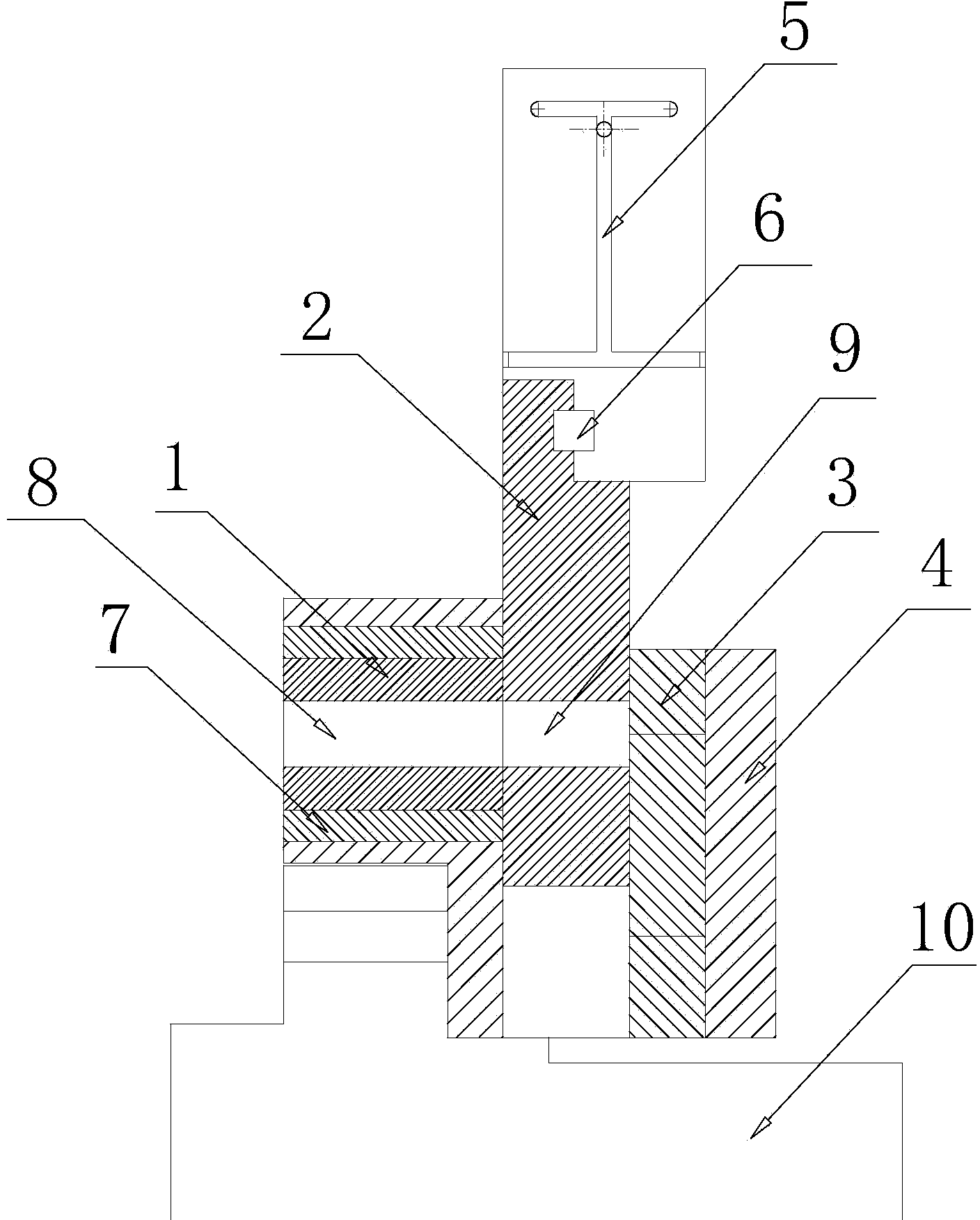

[0010] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a tube and rod cutting machine proposed by the present invention.

[0011] refer to figure 1 , a pipe and rod cutting machine proposed by the present invention is used to cut steel pipes or pipe rods, including a machine base 10, a mold core 1 fixed on the machine base 10, and a movable shearing seat is arranged on one side of the mold core 1 2. The side of the movable shear seat 2 away from the mold core 1 is provided with a cam 3, the side of the mold core 1 close to the movable shear seat 2, the two sides of the movable shear seat 2, and the side of the cam 3 close to the movable shear seat 2 The surface of the base is smooth, and the side of the master form 3 away from the movable shear seat 2 is provided with a formwork 4, the formwork 3 leans against the formwork 4, the formwork 4 is fixed on the machine base 10, and the mold core 1 is provided with a first cavity , the movable shear se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com