Casting method of the middle groove side of the heavy-duty scraper machine

A scraper and groove technology, which is applied in casting molding equipment, molds, cores, etc., can solve problems such as failure to meet quality requirements, poor surface and internal quality of castings, backward technology, etc., and achieve high surface dimensional accuracy, The effect of simple casting process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021] A casting method for the middle groove side of a heavy-duty scraper machine, comprising the following steps:

[0022] (1) Sand mixing: Mix silica sand, water glass and curing agent. The amount of water glass added is 2.2% to 2.5% of the weight of silica sand, and the amount of curing agent added is 15% of the weight of water glass.

[0023] When the lowest temperature of the day is <5°C, turn on the heater of the water glass box, and set the temperature of the heater temperature control switch to 20-35°C.

[0024] Silica sand, water glass and curing agent were purchased from Chengdu Keshen Company.

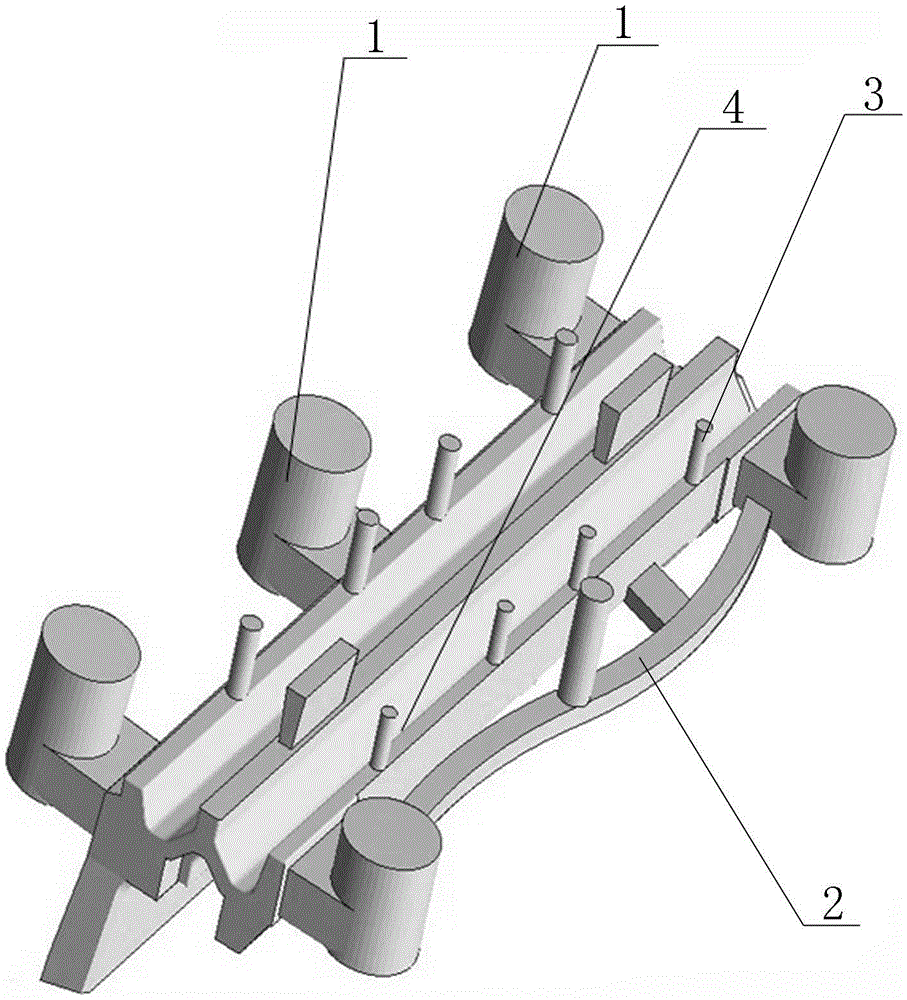

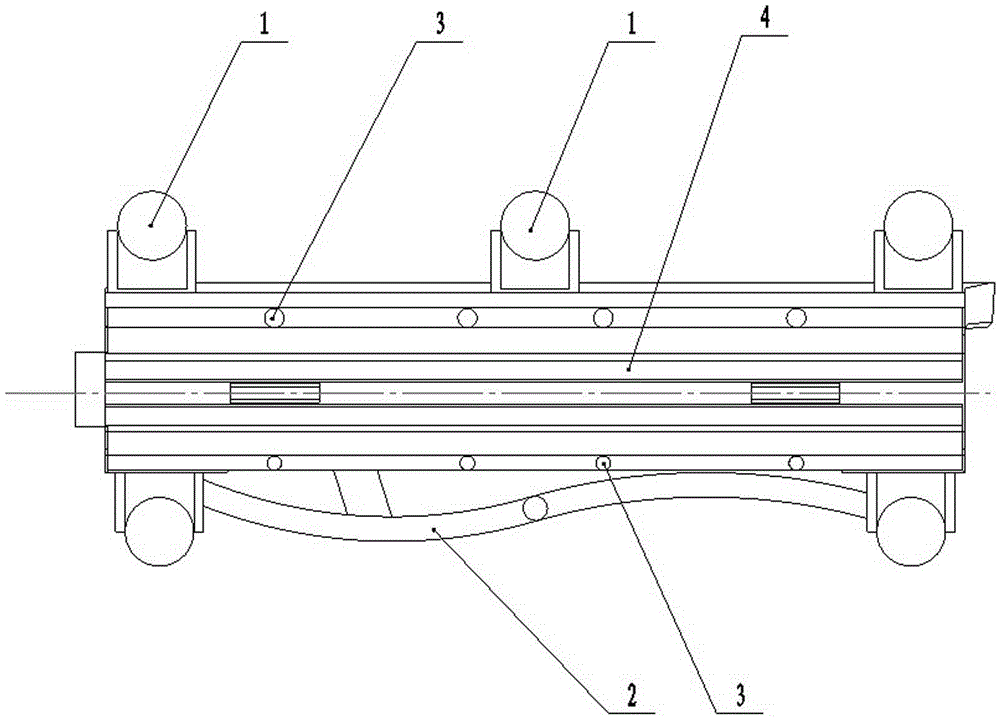

[0025] (2) Modeling: use the mold to prepare the upper box and the lower box, in which the pouring system is distributed on the upper box, such as figure 1 As shown, the four corners of the upper box are respectively provided with a therm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com