Continuously cast bloom shape control method and crystallizer

A control method and crystallizer technology, applied in the field of metallurgy, can solve the problems such as large bulging volume of continuous casting billets affecting the yield of products, and achieve the effects of improving the yield of narrow surface products, less scratches on the edge of the plate, and reducing product retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

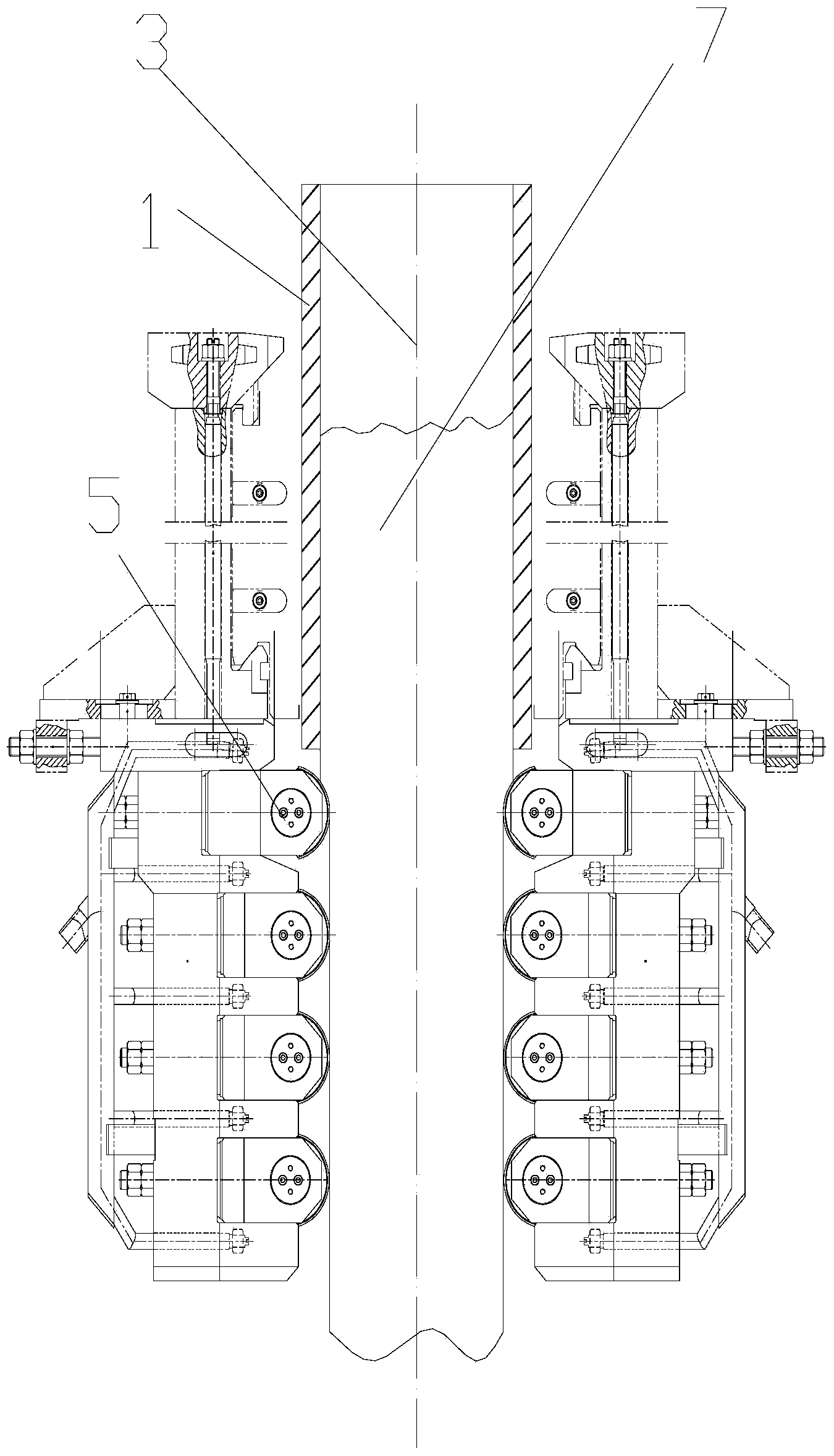

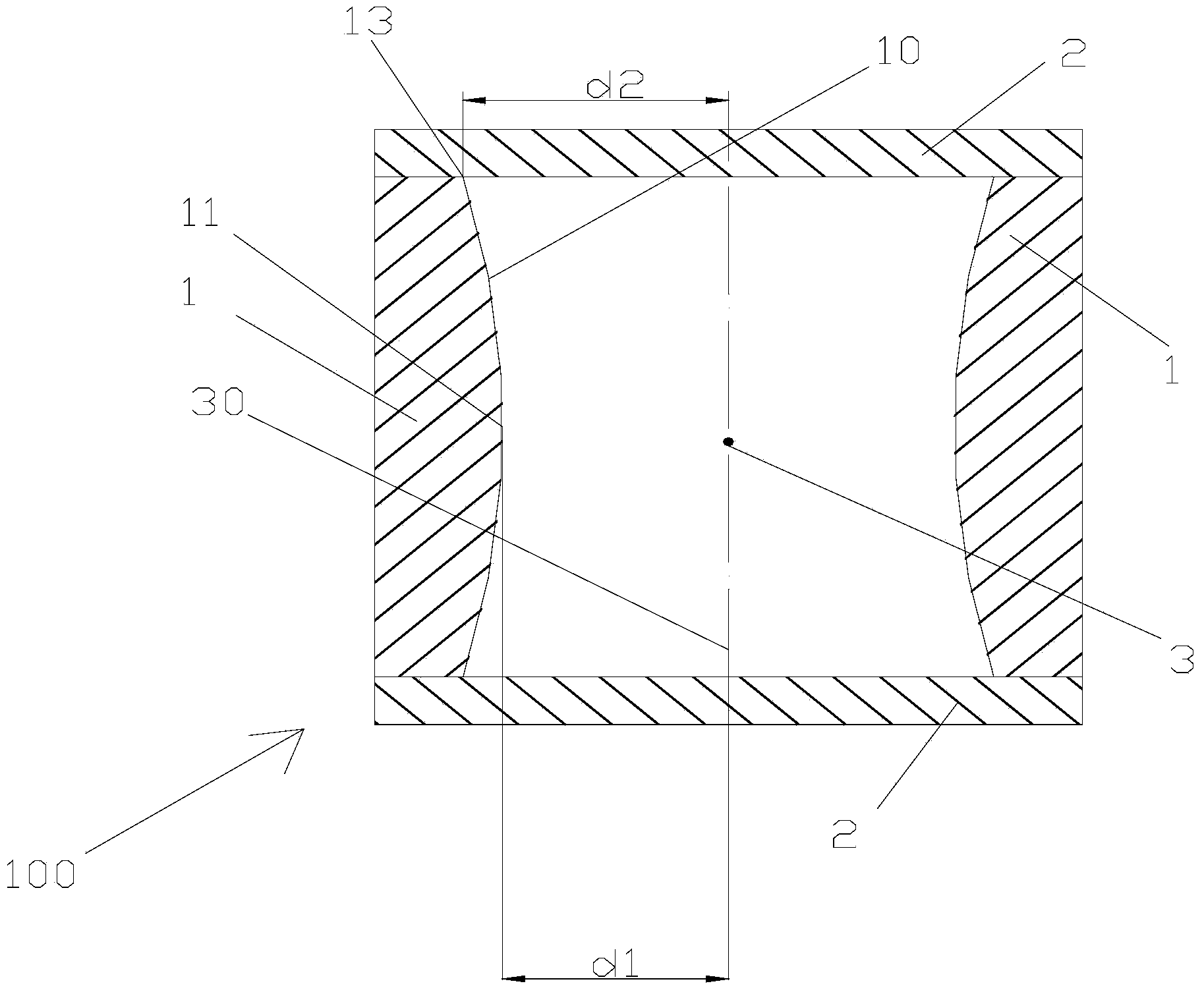

[0032] Such as figure 1 with figure 2 As shown, the continuous casting slab shape control method according to the embodiment of the present invention includes:

[0033] Let the molten steel enter the crystallizer to form a slab;

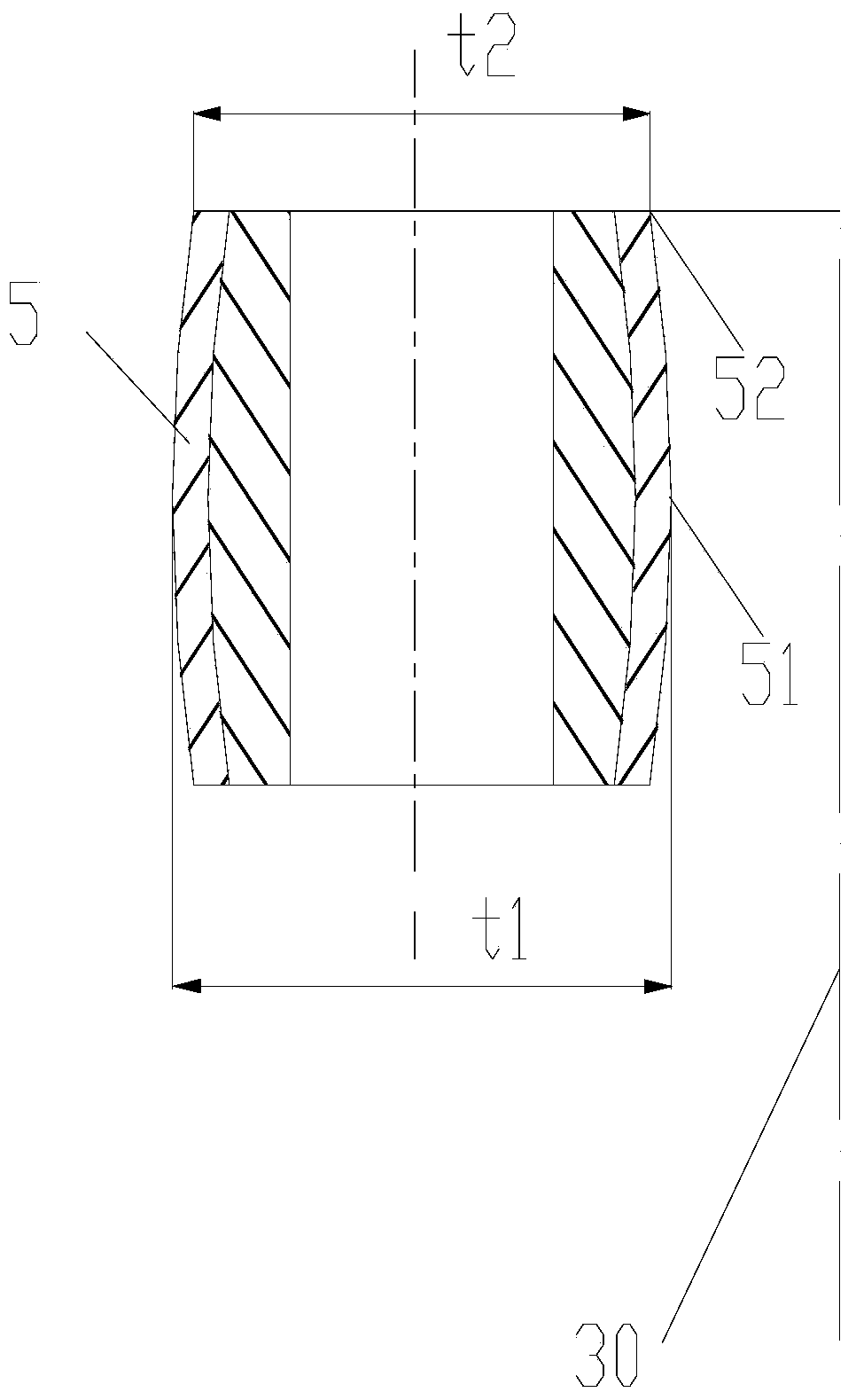

[0034] The crystallizer comprises: the side wall 100 of the crystallizer, and the side wall 100 of the crystallizer comprises: the first pair of side walls 1, the second pair of side walls 2; the crystallizer also includes: the first pair of side walls downstream A first set of side support rolls 5 and a second set of side support rolls located downstream of the second pair of side walls 2, the first pair of side walls 1 and the second pair of side walls 2 respectively comprising two side walls symmetrical about the centerline 3 of the cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com