Self-locking pre-stress buffering device

A buffer device and prestressing technology, applied in the direction of transportation and packaging, vehicles used for freight, load coverage, etc., can solve the problems of easy downward bending deformation, difficult to bear the cover plate, lack of roof beam support, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

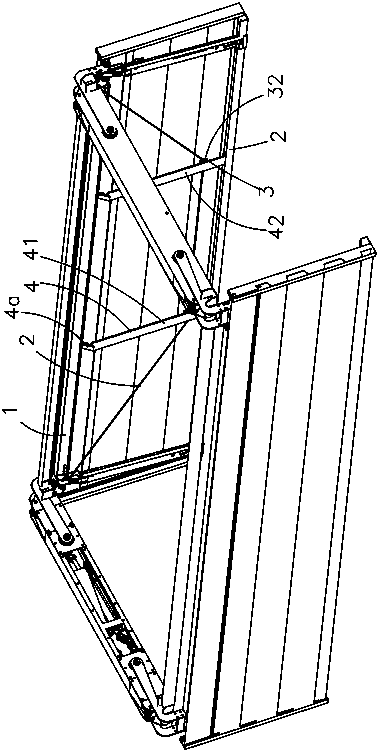

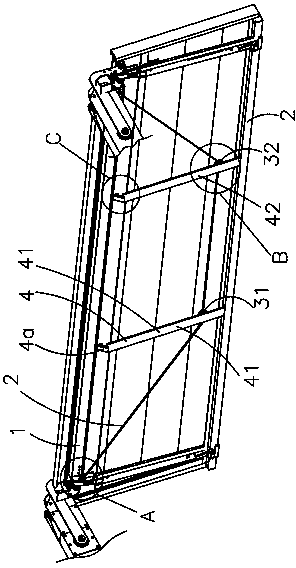

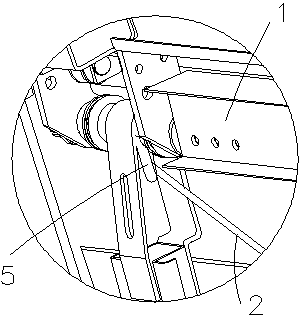

[0024] like Figure 1 to Figure 5 The embodiment shown, the reference number description: cover plate top beam 1, cover plate bottom beam 11, pre-tightening steel cable 2, tensioning device 3, first tensioner 31, second tensioner 32, force component arm 4. Top joint 4a, first force component arm 41 , second force component arm 42 , fixed ear 5 .

[0025] The self-locking prestressed buffer device includes a cover top beam 1 arranged on the top of the cover plate, wherein the lower part of the cover top beam 1 is provided with a pre-tightened steel cable 2, and the two ends of the pre-tightened steel cable 2 are connected to the top of the cover plate respectively. The two ends of the beam 1 are connected, and the tensioning device 3 is provided on the pre-tensioning steel cable 2, and the tensioning device 3 exerts a prestress on the top beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com