Titanium-manganese codoped yttrium oxide light-emitting film and preparation method thereof, and electroluminescence device

A technology for electroluminescent devices and light-emitting films, which are used in chemical instruments and methods, light-emitting materials, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

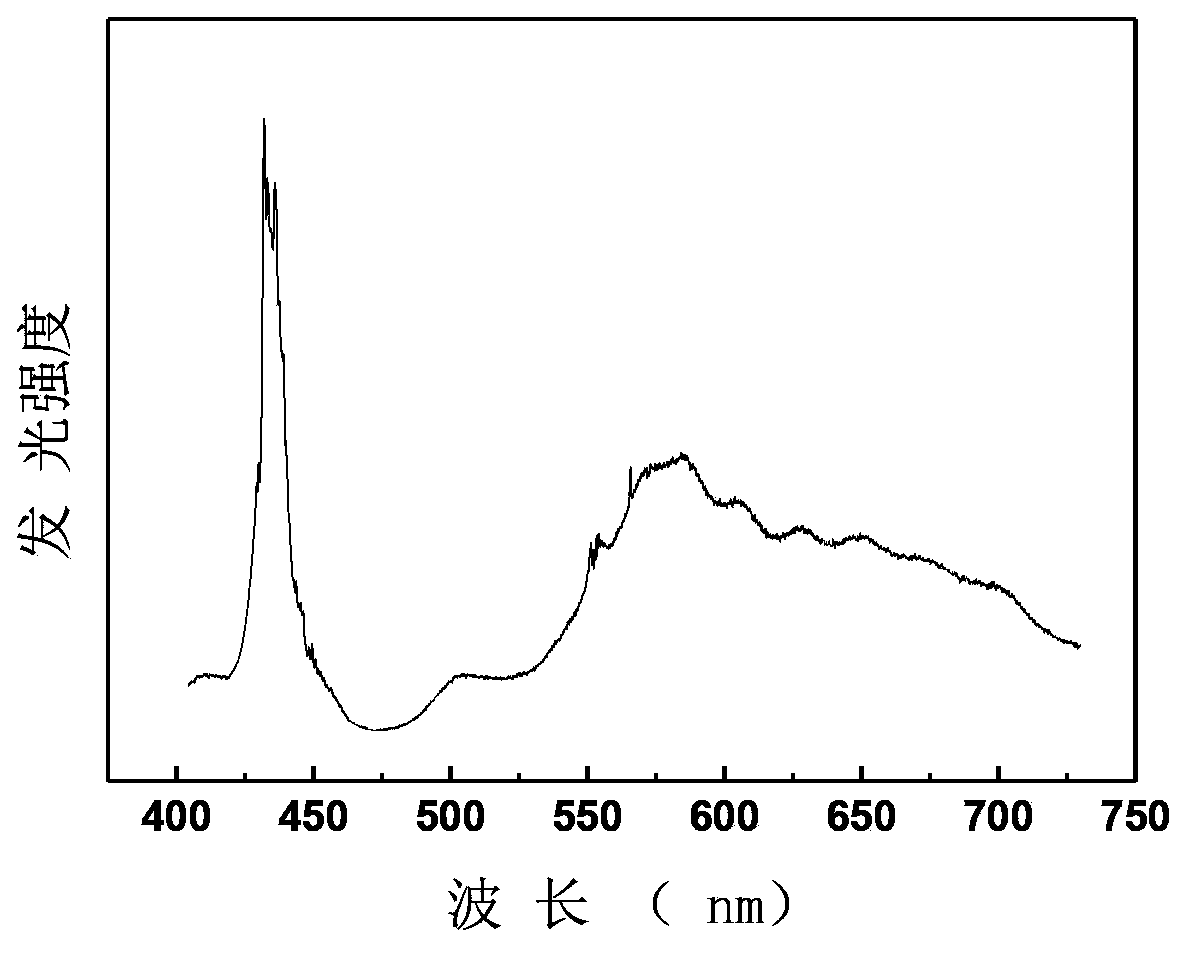

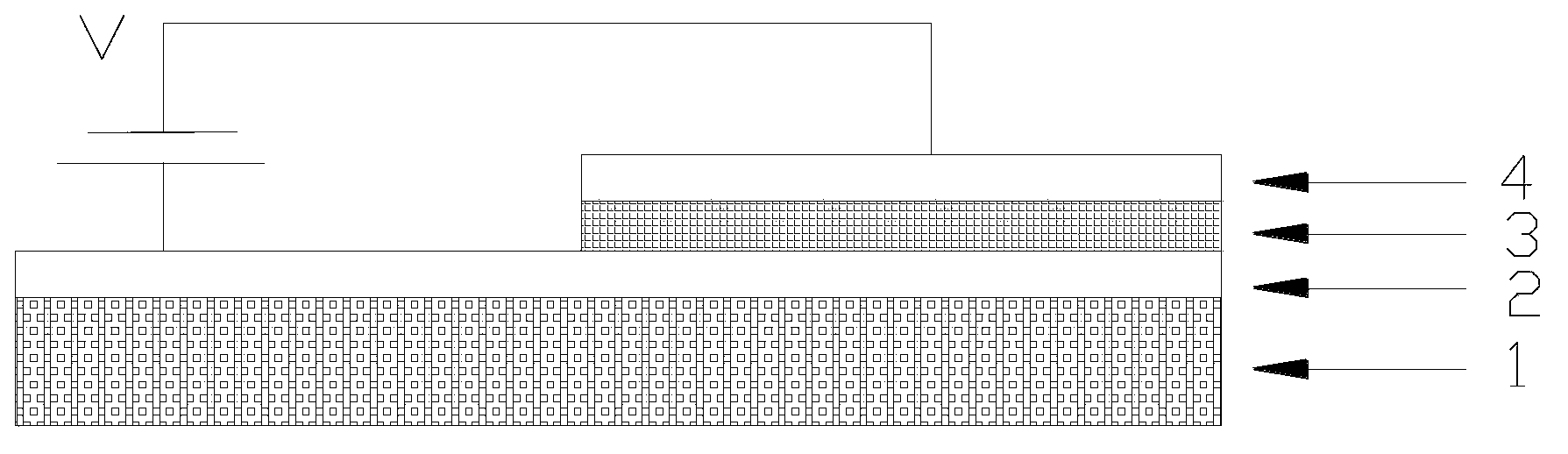

[0024] Choose TiO 2 , MnO 2 , Y 2 o 3 The molar weights of the powders are: 0.04mmol, 0.08mmol and 0.94mmol respectively. After the powders are evenly mixed, they are sintered at 1250°C for 3 hours, and after cooling, they are cut into Φ50×2mm ceramic targets, and the ceramic The target is put into the vacuum chamber of the coating equipment. Then, the glass with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, and treated with oxygen plasma, and placed in a vacuum chamber. The distance between the ceramic target and the ITO glass is set to 60mm. Use a mechanical pump and a molecular pump to pump the vacuum of the cavity to 5.0×10 -4 Pa, the working gas flow rate of oxygen is 20sccm, the working pressure is adjusted to 3Pa, the temperature of ITO glass is 500°C, the laser energy is 150W, and then the film forming process is carried out. After the completion, a titanium-manganese co-doped yttrium oxide luminescent film is obta...

Embodiment 2

[0027] Choose TiO 2 , MnO 2 , Y 2 o 3 The molar weights of the powders are: 0.02mmol, 0.02, and 0.98mmol respectively. After the powders are uniformly mixed, they are sintered at 900°C for 0.5h. After cooling, they are cut into Φ50×2mm ceramic targets, and the ceramic The target material is loaded into the vacuum chamber of the coating equipment. Then, the glass with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, and treated with oxygen plasma, and placed in a vacuum chamber. The distance between the ceramic target and the ITO glass is set to 45mm. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 1.0×10 -3 Pa, the working gas flow rate of oxygen is 10sccm, the working pressure is adjusted to 0.5Pa, the temperature of ITO glass is 250°C, the laser energy is 80W, and then the film making process is carried out. For: Y 2 o 3 :0.01Ti 4+ ,0.01Mn 4+ .

Embodiment 3

[0029] Choose TiO 2 , MnO 2 , Y 2 o 3 The molar weights of the powders are: 0.08mmol, 0.16mmol, and 0.88mmol respectively. After the powders are uniformly mixed, they are sintered at 1300°C for 5 hours, and after cooling, they are cut into Φ50×2mm ceramic targets, and the ceramic The target material is loaded into the vacuum chamber of the coating equipment. Then, the glass with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, and treated with oxygen plasma, and placed in a vacuum chamber. Set the distance between the ceramic target and the ITO glass as 95mm. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 1.0×10 -5 Pa, the working gas flow rate of oxygen is 40sccm, the working pressure is adjusted to 5Pa, the temperature of ITO glass is 750°C, and the laser energy is 300W, and then the film forming process is carried out. : Y 2 o 3 : 0.04Ti 4+ ,0.08Mn 4+ .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com