Manufacturing method of rotary type guiding frame

A guide frame and rotary technology, applied in the field of mining equipment, can solve problems such as redoing and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

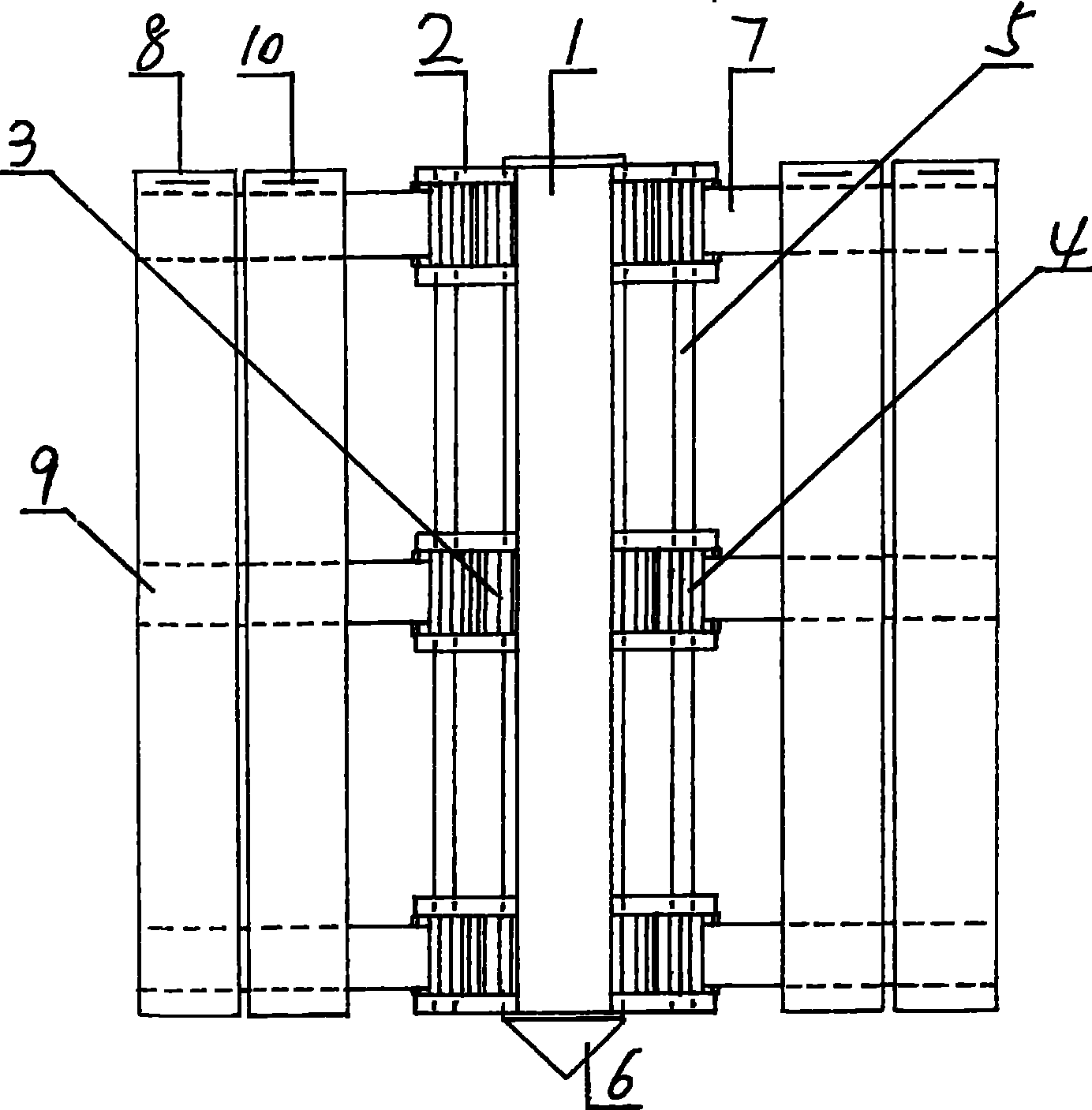

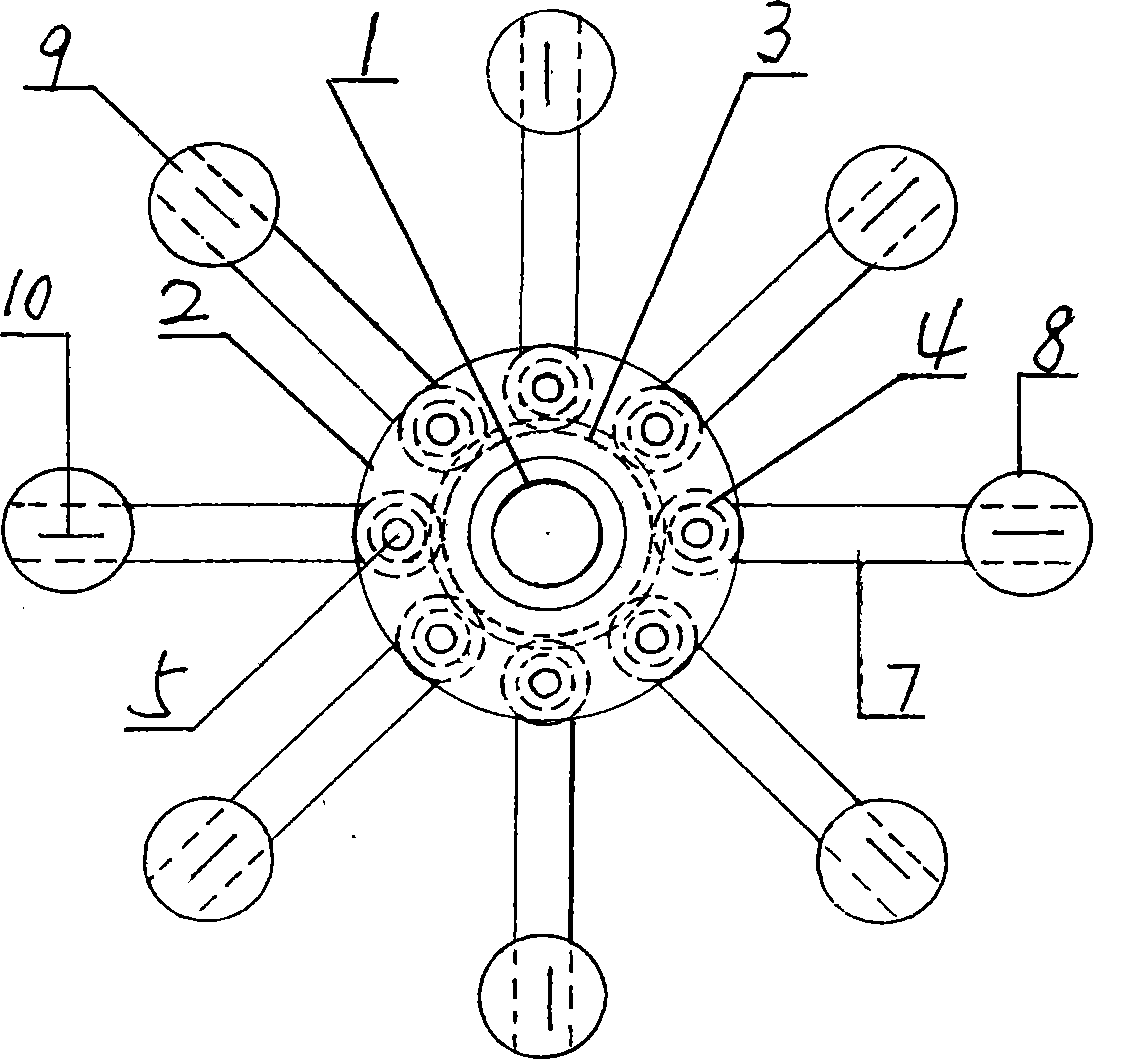

[0006] Such as figure 1 , 2 As shown, there is provided a method for making a rotary guide frame for shaft wall prefabrication. This guide frame has the function of changing the diameter, that is, it can be large or small, so as to achieve the general purpose. Its structure is made up of central column 1, circular ring 2, rotating disc 3, gear 4, gear shaft 5, guide arm 7 and vertical beam 8. The central column 1 adopts a section of hollow cylinder, and its bottom is a cone 6, which is beneficial to align the center of the circle and locate it on the basis. A plurality of rings 2 are arranged on the central column 1, and the rings 2 are made of steel plates, and the rings 2 are in groups of two, and a rotating disk 3 is arranged in the middle of each group of rings 2, and the rotating disk 3 and the ring 2 are set together on the central column 1, and the circular ring 2 of each group is connected to the central column 1 by welding to form a whole, and the circular ring 2 pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com