Method for determining the height and pipe diameter of internal combustion engine smoke exhaust pipe and internal combustion engine

A technology for smoke exhaust pipes and determination methods, which is applied in the directions of machines/engines, exhaust devices, mechanical equipment, etc., can solve problems such as the unsuitability of exhaust pipes for internal combustion engines, achieve fast and effective calculation, improve calculation accuracy, and reduce chimneys high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

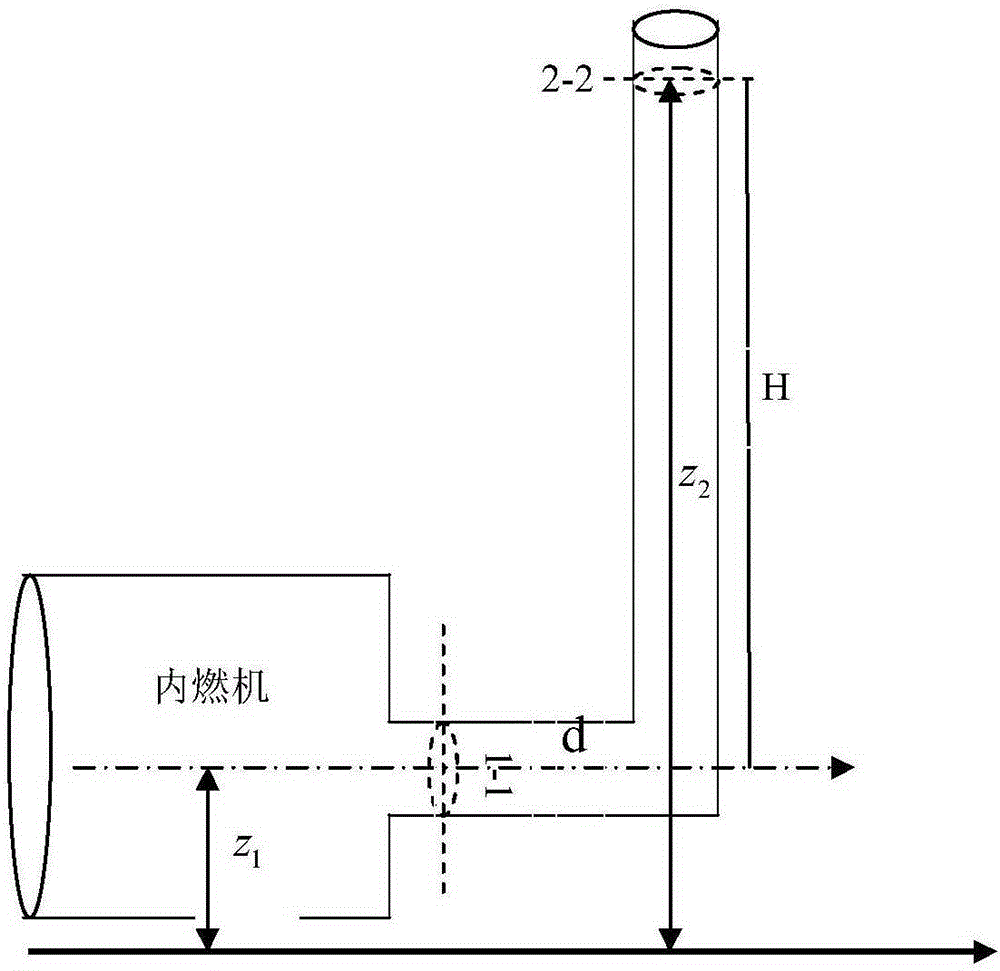

[0059] Experimental example 1: the smoke transmission mode that the present invention adopts sees figure 1 , the flue gas inlet is section 1-1, the flue gas outlet is section 2, the diameter of the exhaust pipe is d, and the height of the exhaust pipe is H.

[0060] The present invention utilizes gas flow rate, flow velocity, smoke exhaust pipe diameter, air leakage coefficient, etc. to reasonably design the size of the height of the internal combustion engine smoke exhaust pipe and the size of the cross-sectional inner diameter, and the steps are as follows:

[0061] 1) The smoke exhaust pipe is based on the steel body material, using the JMS620 internal combustion engine flue flow Q=5.214kg / s provided by the manufacturer to calculate, the diameter of the smoke exhaust pipe is d=900mm, the vacuum degree is not less than 10mm water column, the exhaust pipe exhaust The temperature of the smoke is 160°C; the outlet pressure is 1.01×10 5 Pa;

[0062] 2) From the boiler design m...

experiment example 2

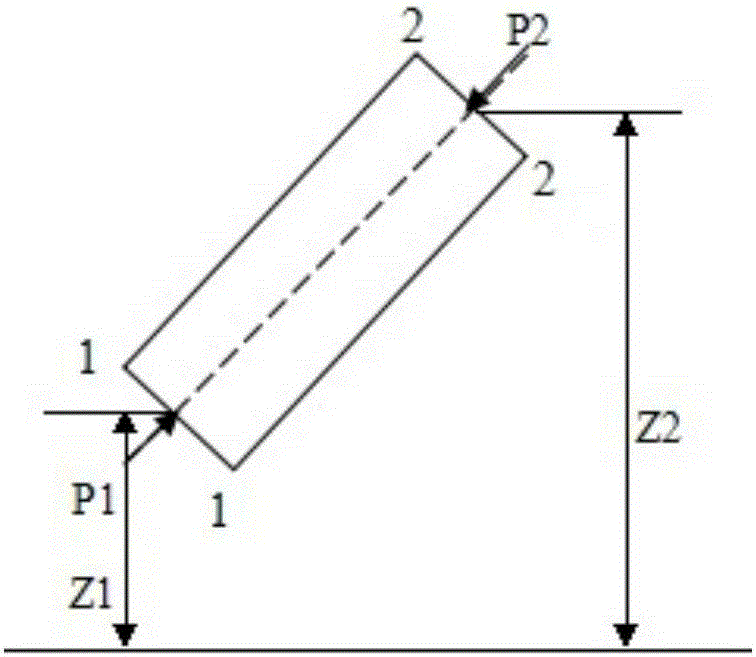

[0066] Experimental example 2: the energy conservation equation of the exhaust pipe among the present invention obtains like this: as figure 2 As shown, columns 1-1 and 2-2 section the Bernoulli equation:

[0067] z 1 + p 1 a b s ρ g + V 1 2 2 g = z 2 + p 2 a b s ρ g + V 2 2 2 g + h w ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com