An Optical Modeling and Calculation Method Based on Hankel Transform and Beam Propagation Method

A calculation method, Hankel's technology, applied in optics, optical components, design optimization/simulation, etc., to achieve high degree of freedom, improve calculation efficiency, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

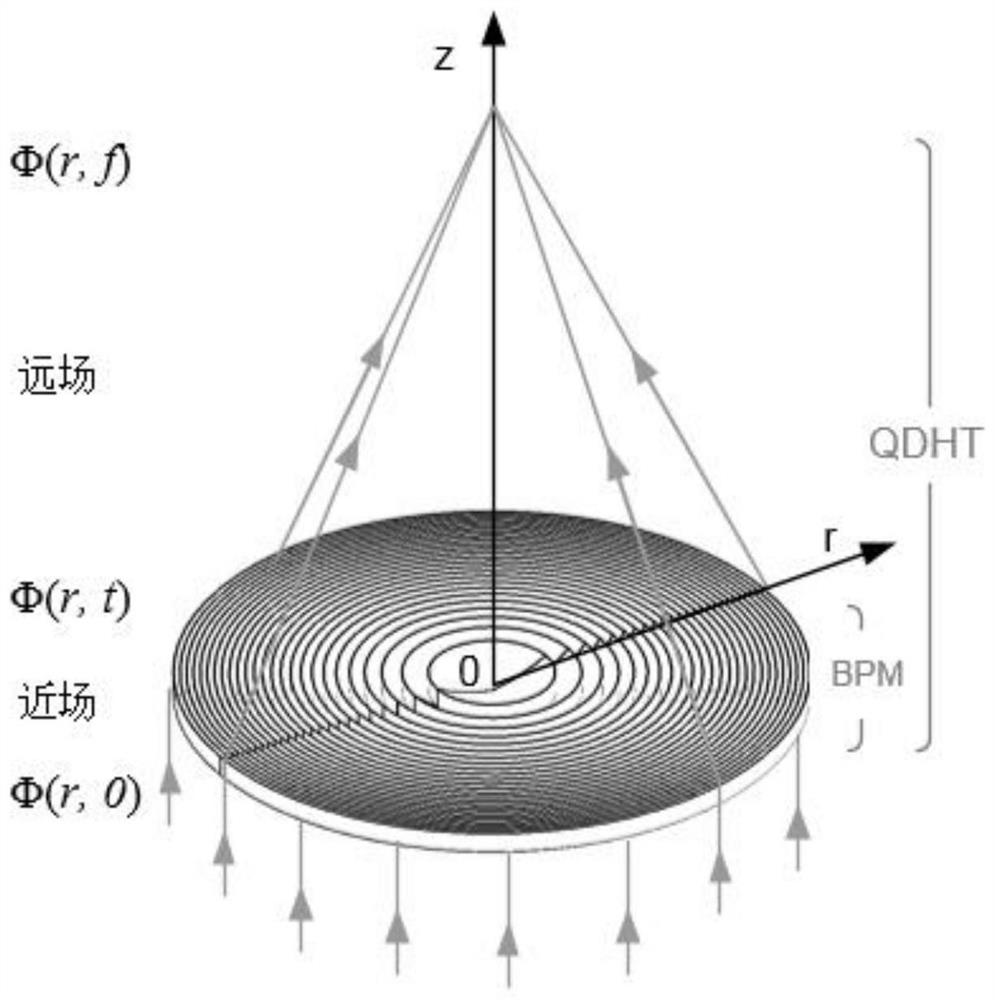

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: Calculate the focusing process of the circular HSQ Kinoform optical element with high efficiency focusing under 500eV energy, the specific steps are:

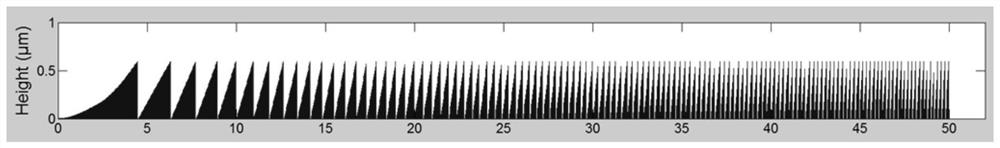

[0057] (1) Set the energy of the incident light field as 500eV, and the plane wave with unit amplitude is incident vertically. The diameter of HSQ Kinoform optical element is 100μm, the thickness is 600nm, the width of the outermost ring is 200nm, the focal length is 4.03mm, the material is silicon dioxide, and the shape is an ideal Kinoform distribution. The cross section along the radial direction is as follows: figure 2 shown.

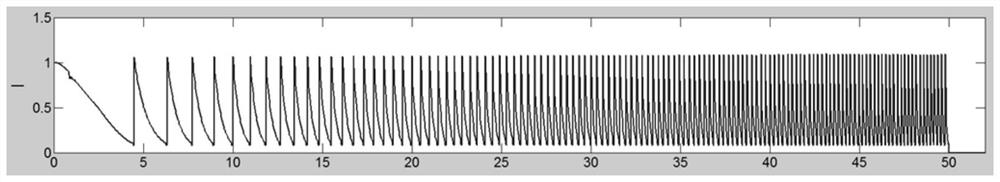

[0058] (2) The near field of the optical element is calculated by the beam propagation method and the Hankel transformation. The sampling points along the radial direction of the optical element are 2048, the sampling points in the near-field propagation direction are 1024, and the sampling points in the far-field propagation direction are 1024. The distribution of the calcula...

Embodiment 2

[0061] Embodiment 2: Calculate the focusing process of the shape-optimized circular AuKinoform optical element under 8keV energy and its focusing efficiency under different thicknesses. The specific steps are:

[0062] (1) Set the energy of the incident light field as 8000eV, and the plane wave with unit amplitude is incident vertically. The diameter of the AuKinoform optical element is 100μm, the thickness is 2000nm, the width of the outermost ring is 500nm, the focal length is 161mm, the material is gold, and the shape is the optimized Kinoform distribution. The cross section along the radial direction is as follows: Figure 8 shown.

[0063] (2) The near field of the optical element is calculated by the beam propagation method and the Hankel transformation. The sampling points along the radial direction of the optical element are 2048, the sampling points in the near-field propagation direction are 1024, and the sampling points in the far-field propagation direction are 10...

Embodiment 3

[0067] Embodiment 3: Calculate the focusing process of the complex zone plate optical element with shell structure under 5keV energy, the specific steps are:

[0068] (1) Set the energy of the incident light field as 5000eV, and the plane wave with unit amplitude is incident vertically. The diameter of the composite zone plate optical element is 100 μm, the thickness is 2000 nm, the outermost ring width is 500 nm, the focal length is 100.8 mm, and the diameter of the beam stopper is 40 μm. The inner material of the optical element is silicon dioxide, the outer shell material is gold, the thickness is 200nm, and the shape is optimized Kinoform distribution. The cross section along the radial direction is as follows: Figure 14 shown.

[0069] (1) The near field of the optical element is calculated by the beam propagation method and the Hankel transformation. The sampling points along the radial direction of the optical element are 2048, the sampling points in the near-field p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com