Novel hydraulic oil cylinder

A hydraulic cylinder, a new type of technology, applied in the direction of fluid pressure actuators, engine components, cylindrical pistons, etc., can solve problems such as unreliable connections, broken ferrules, and prone to fatigue, so as to achieve clean and thorough exhaust gas and long service life Good effect of growth and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

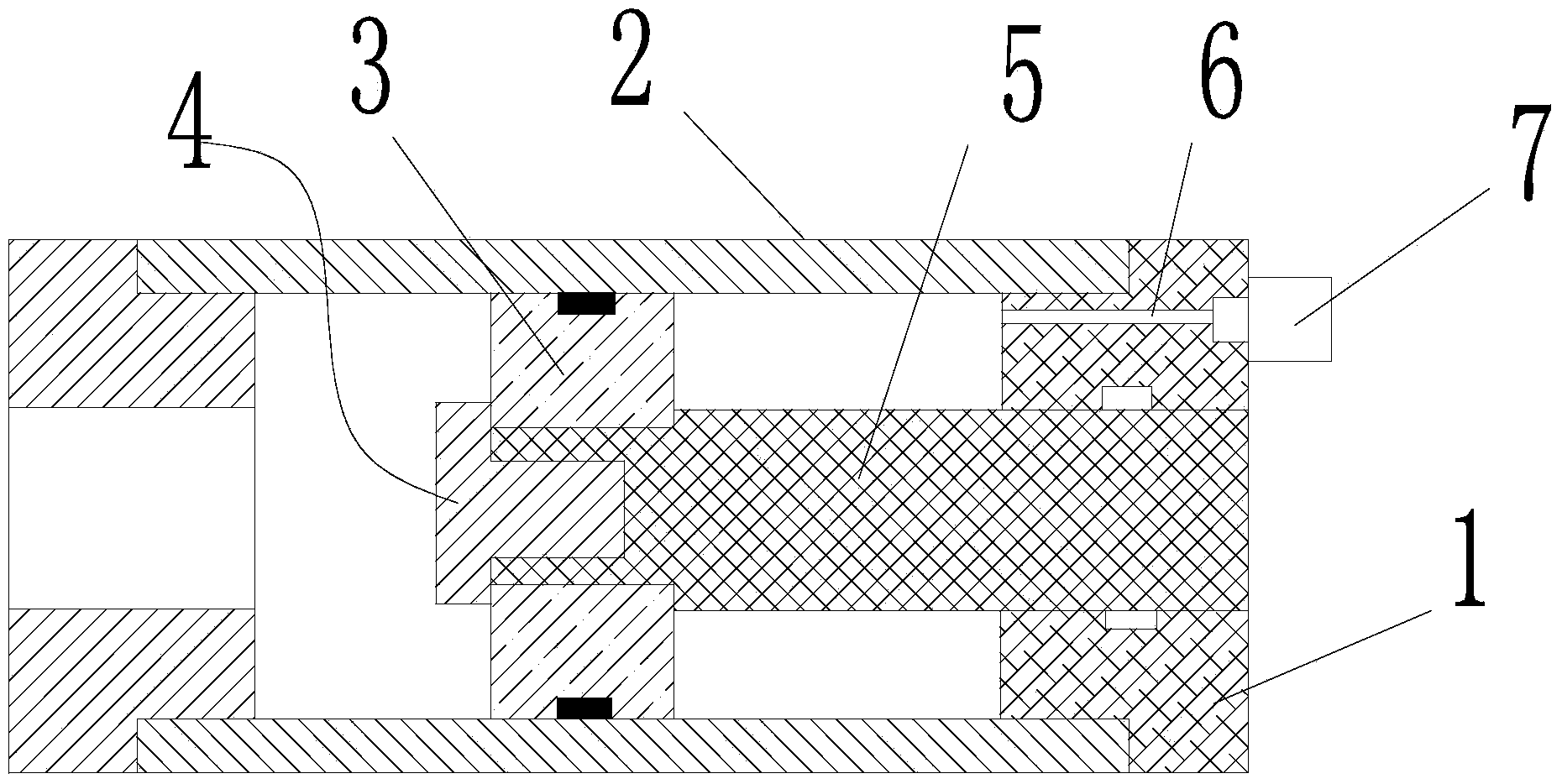

[0016] Such as figure 1 As shown, a new type of hydraulic oil cylinder includes a cylinder body 2, a front end cover, a rear end cover 1, a piston 3 and a piston rod 5. The front end of the piston rod 5 is stepped, and the front end surface of the piston rod 5 is provided with a threaded hole. 3 is socketed on the front end of the piston rod 5, and fixed by matching bolts and threaded holes, and an exhaust valve 7 is fixed on the rear end cover 1, and a channel 6 is provided on the exhaust valve 7 to communicate with the cylinder body 2.

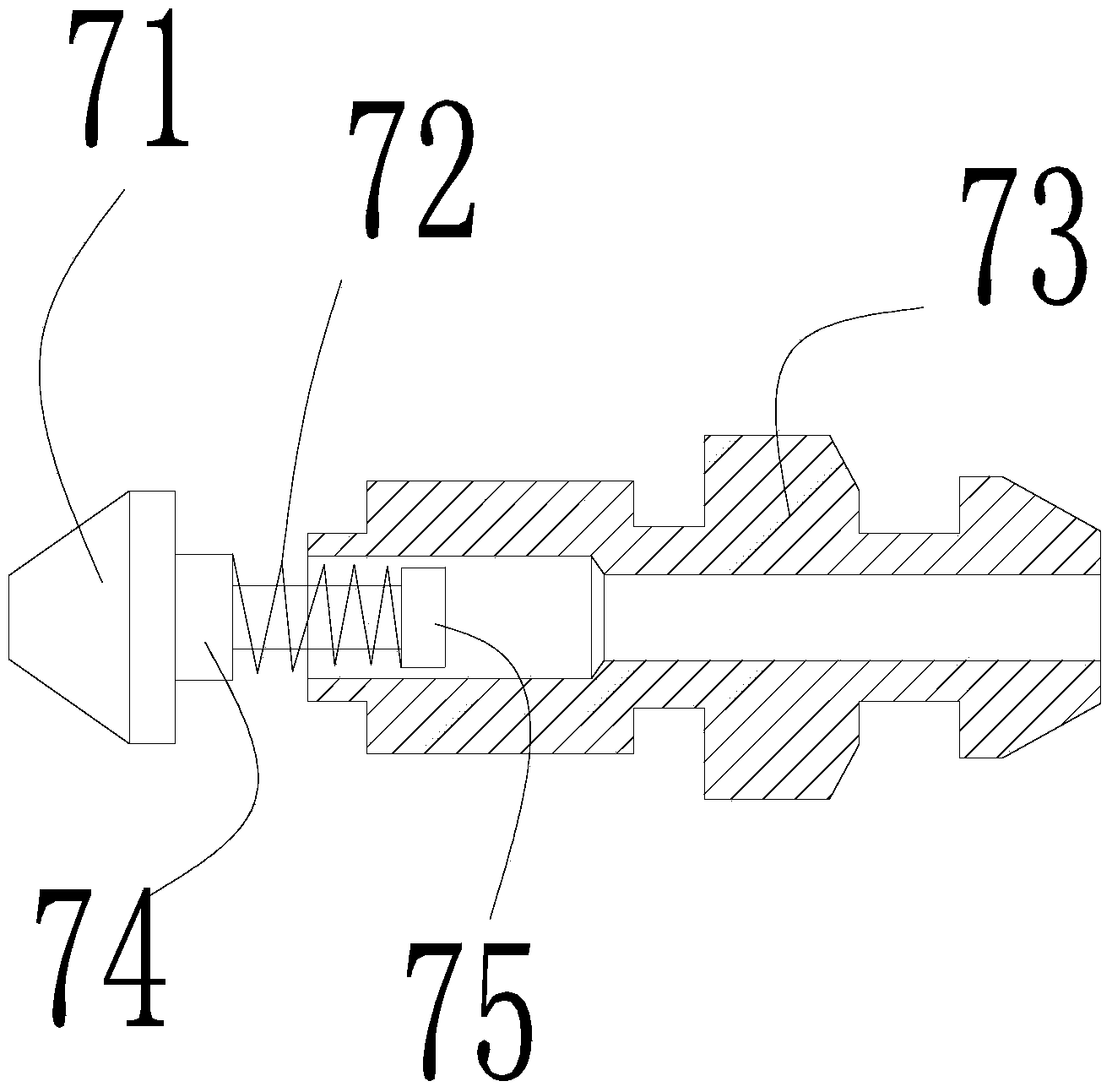

[0017] Such as figure 2 As shown, the exhaust valve 7 includes a valve 71, a spring 72, a valve housing and a valve body 73, the valve body 73 has an inner hole, the valve housing is embedded in one end of the inner hole of the valve body 73, and a spring seat 74 is installed on one end of the valve stem. , the valve is connected through the spring seat 74, the spring 72 is sleeved on the valve stem and the spring seat 74 and placed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com