a heat sink

A heat sink, cylindrical technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc. Heat dissipation requirements, convenient connection, and ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

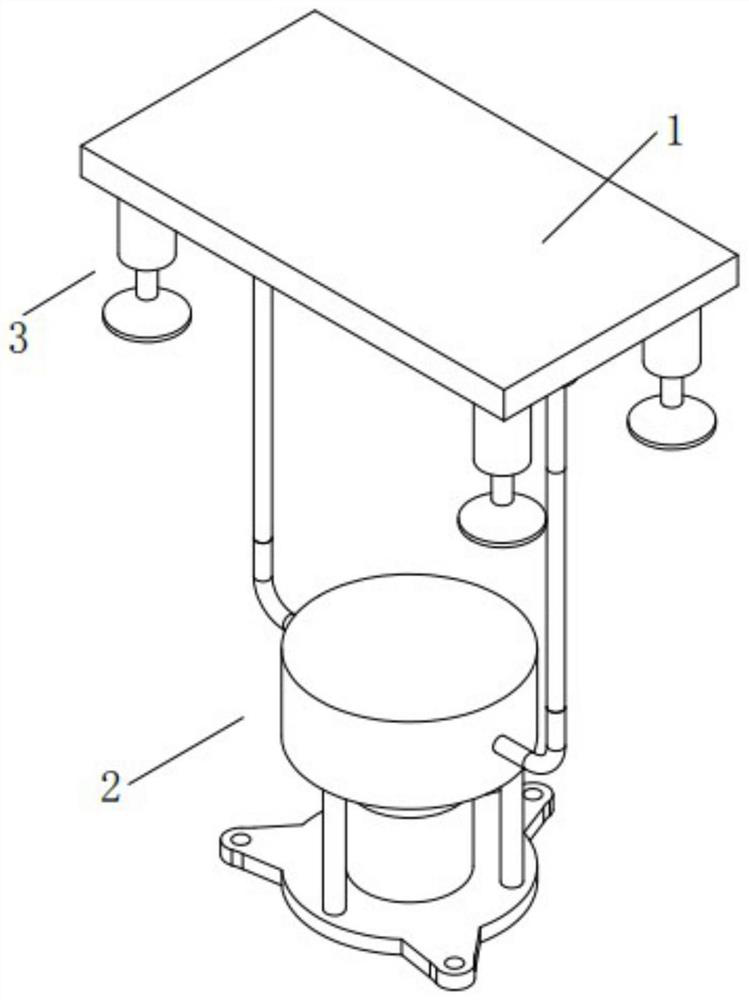

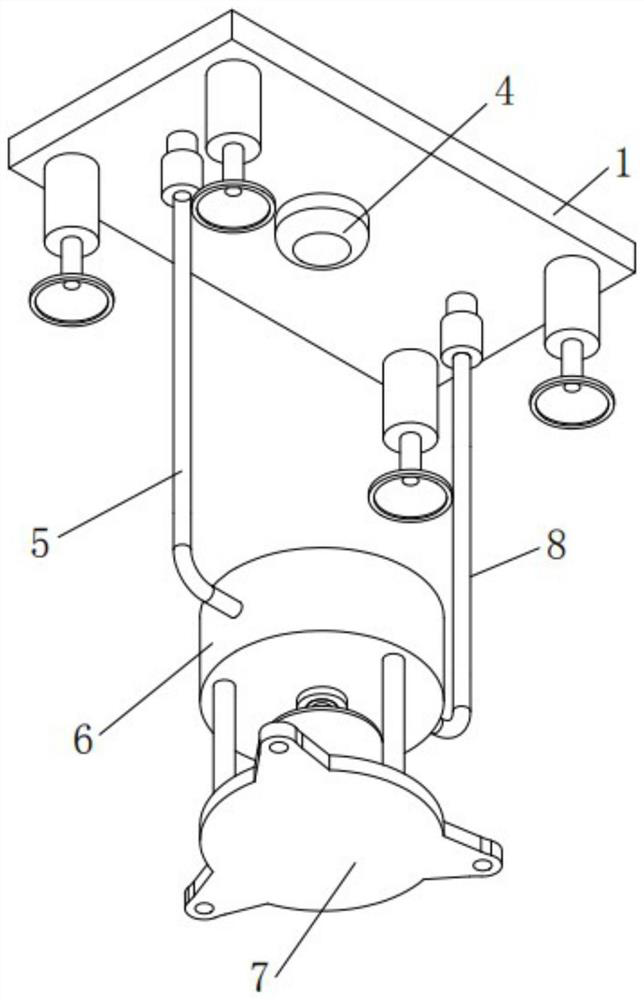

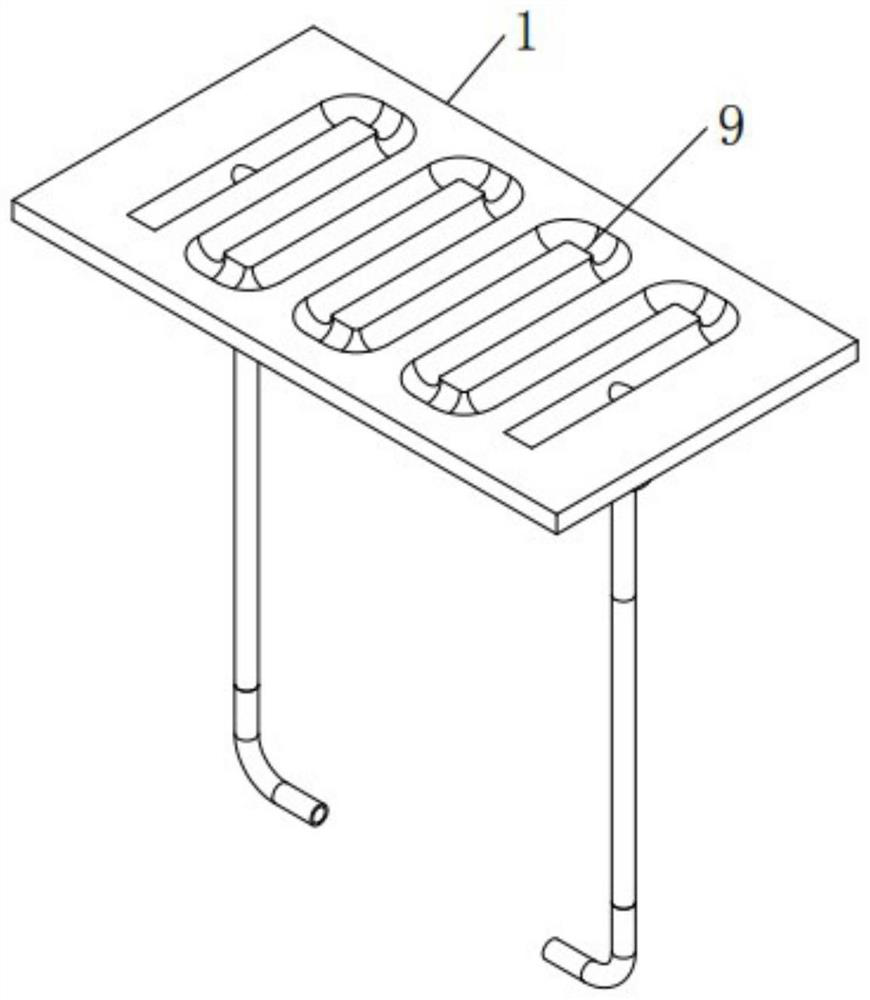

[0031] A heat sink, such as Figure 1-4 As shown, it includes an alloy substrate 1 and a cooling liquid circulation mechanism 2, the cooling liquid circulation mechanism 2 is arranged in cooperation with the alloy substrate 1, an S-shaped channel 9 is reserved inside the alloy substrate 1, and the alloy A first connection nozzle 10 and a second connection nozzle 16 are symmetrically and fixedly installed on one side of the substrate 1, the first connection nozzle 10 communicates with one end of the S-shaped passage 9, and the second connection nozzle 16 communicate with the other end of the S-shaped channel 9;

[0032] Such as Figure 2-7As shown, the cooling liquid circulation mechanism 2 includes a base 7, a cylindrical sealed casing 6 filled with cooling liquid, a first connecting pipe 5, a first locking cap 11, a second connecting pipe 8, a second lock Tight cap 15, connecting seat 23, connecting shaft 18, cylindrical mounting seat 19, blade 17 and motor 20, the base 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com