Ultrasonic testing method of thin friction?material layer structure sliding?bearing lubrication?film thickness

A friction material, sliding bearing technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve problems such as thickness measurement of lubricating film of difficult-to-slide bearings, and achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

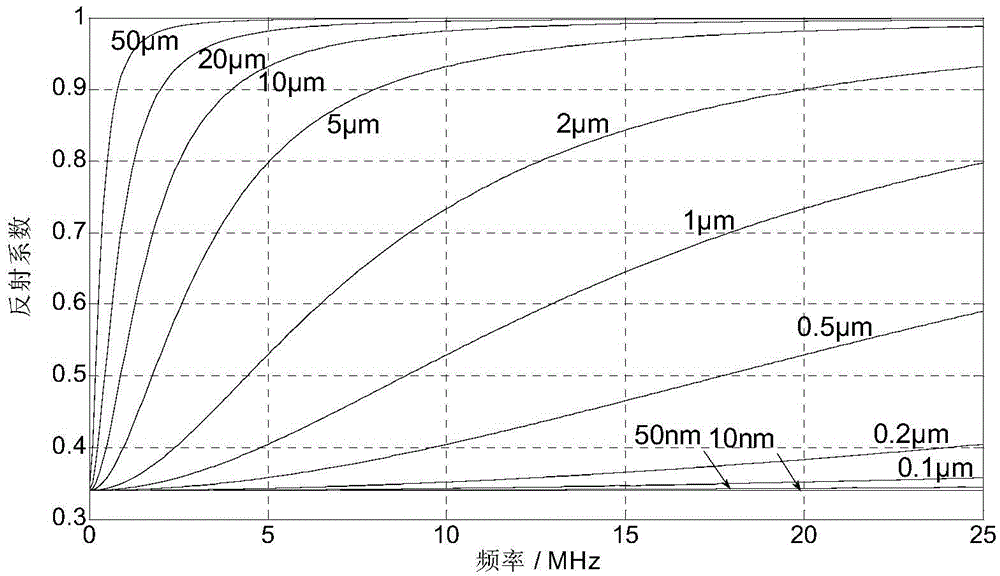

[0085] Taking the actual measurement of the lubricating film thickness of a thrust sliding bearing with a 0.5mm thick Babbitt alloy lining as an example, a film thickness simulation device is designed, and a high-precision piezoelectric actuator with closed-loop control is used to generate lubricating film layers of different thicknesses , the film thickness measurement results obtained by the method of the present invention are compared with the feedback thickness of the piezoelectric actuator, which illustrates the effectiveness of the ultrasonic detection method of the present invention. The reflection coefficient of the echo signal at different film thicknesses is measured as Figure 11 As shown, the set film thickness in the figure is the film thickness value displayed by the reading of the closed-loop piezoelectric actuator. According to the reflection coefficient result, the film thickness measurement result obtained from formula (3) is compared with the set film thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com