Waste water recycling?device for water purifying machine and control method thereof

A waste water circulation and water purifier technology, applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve the problem of waste of water resources and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

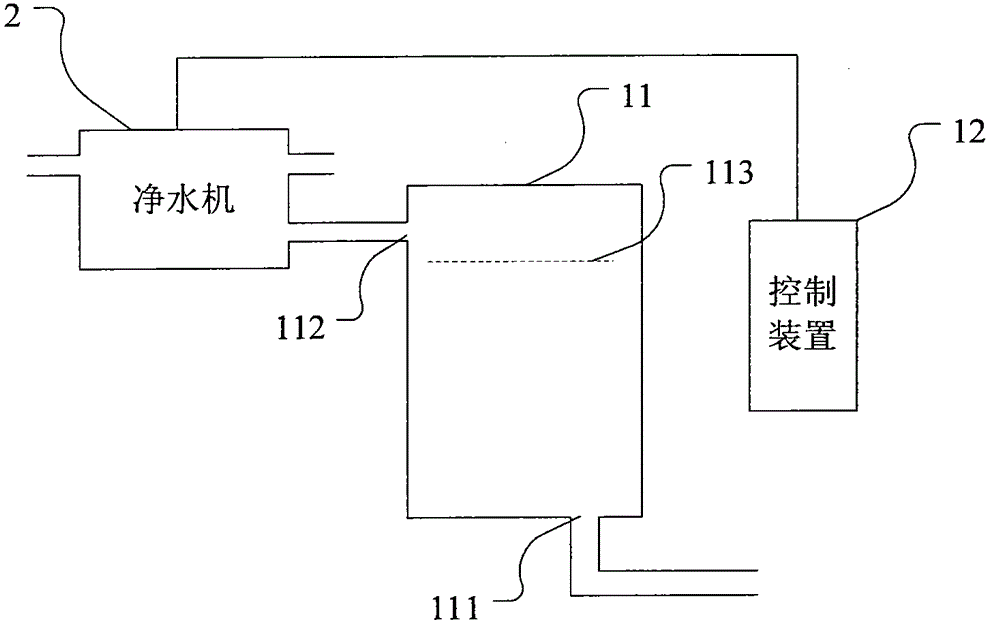

[0026] figure 1 A schematic diagram of a waste water recycling device for a water purifier and a water purifier according to an embodiment of the present invention is shown. The waste water recycling device of the water purifier includes a waste water storage device 11, and the waste water storage device 11 has a A container for containing waste water, the waste water storage device 11 has a water inlet 112 and a water outlet 111 . The water inlet 111 and the water outlet 112 communicate with the container in the waste water storage device 11 .

[0027] In addition, the wastewater recycling device of the water purifier also includes a control device 12 .

[0028] The water inlet 112 of the waste water storage device 11 is connected to the waste discharge port 21 of the water purifier 2, so that the water purifier 2 discharges waste water into the waste water storage device 11 for storage when the water purifier 2 is in operation. Waste water passing through the water purifie...

Embodiment 2

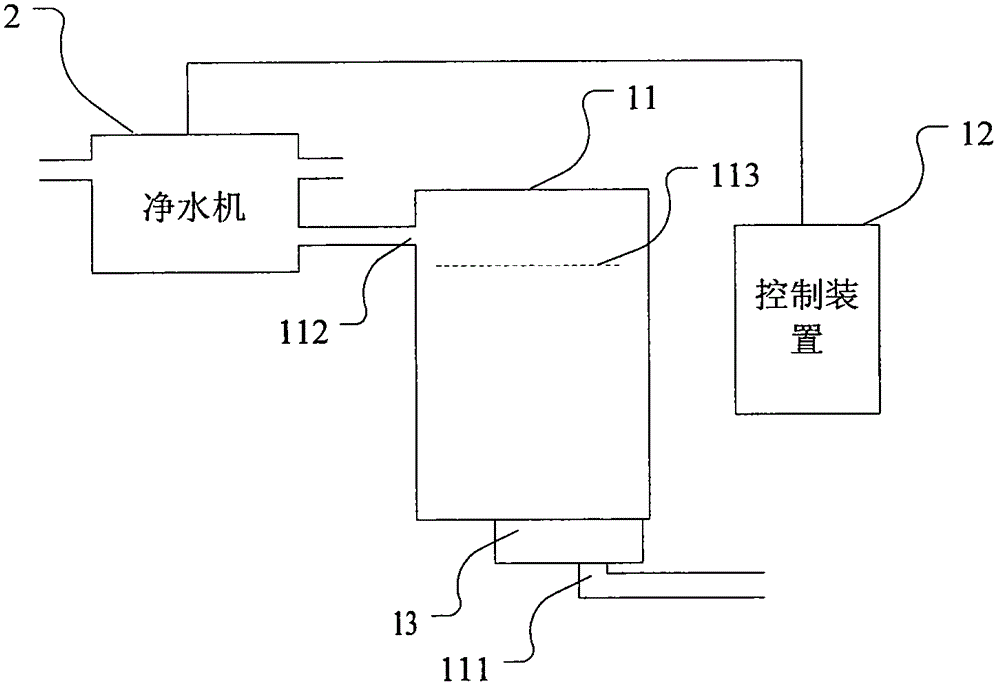

[0034] figure 2 A schematic diagram of the waste water recycling device and the water purifier provided in this embodiment is shown. The difference between the waste water recycling device of the water purifier and the waste water recycling device of the water purifier in Embodiment 1 is only that : In the waste water recycling device 1 ' of the water purifier, a booster device 13 is added, wherein figure 2 Winning mark and figure 1 Components with the same reference number have the same composition structure and function, and will not be repeated here.

[0035] refer to figure 2 , in this embodiment, the waste water storage device 11 discharges water through the water outlet into the external pipeline through the pressurization device for use by users.

Embodiment 3

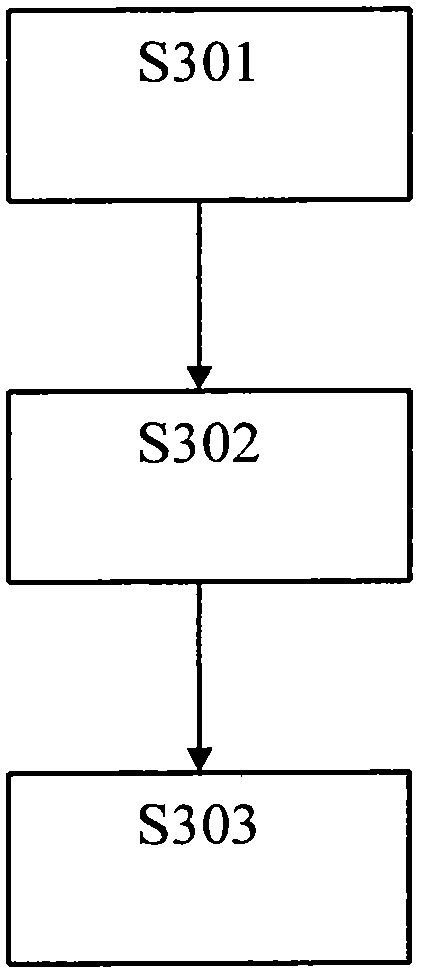

[0037] image 3 It shows a schematic diagram of a control method of a waste water recycling device of a water purifier correspondingly provided by the present invention, the waste water recycling device of the water purifier includes a waste water storage device and a control device, and the waste water storage device includes a device for containing A container device for waste water, the container device has a water inlet and a water outlet, and a high water level mark is set on the upper position in the waste water storage device, such as image 3 As shown, the method includes the following steps:

[0038] Step S301: Detect the water level in the waste water storage device 11;

[0039] Step S302: When it is determined that the water level in the waste water storage device is higher than or reaches the high water level mark, control the water purifier to stop working;

[0040] Step S303: When it is determined that the water level in the waste water storage device is lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com