A Substrate Processing Method for Improving Accuracy or Consistency of Emission Compensation Temperature Measurement

A processing method and consistent technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as lack of consistency and reproducibility, inaccurate temperature calculation, "pattern recognition" errors, etc., to improve the accuracy of temperature measurement Sex, enhance the effect of reflected signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

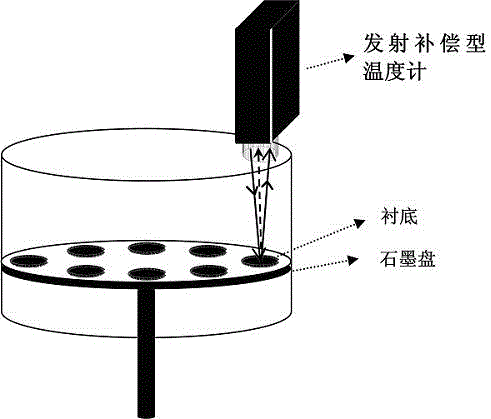

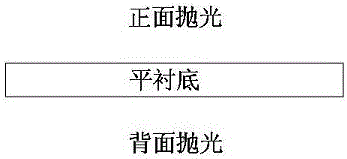

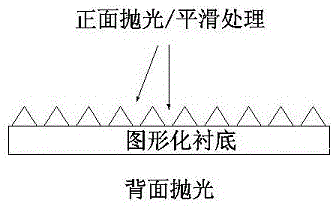

[0023] see figure 2 and image 3 , the steps of the processing method of the present invention are as follows: for a substrate with a transparent wavelength of detection light, the flat substrate is subjected to double-sided polishing; then the front of the flat substrate is subjected to a dry etching process to make a pyramid-shaped figure to form a patterned substrate, The surface of the front pattern of the patterned substrate is flattened and smoothed, and the uniformity of the geometric characteristics of the pattern structure is maintained, and the back of the patterned substrate is polished. For the non-transparent substrate of the detection light wavelength, only the front side of the flat substrate is polished; then the front side of the flat substrate is subjected to a dry etching process to make a pyramid-shaped pattern to form a patterned substrate, and the front side of the patterned substrate is patterned The surface is smoothed and smoothed, and the uniformity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com