A preparation method of lithium-nickel-manganese composite oxide for high-voltage positive electrode material of lithium-ion battery

A lithium-ion battery and composite oxide technology, applied in battery electrodes, nickel compounds, manganese compounds, etc., can solve problems such as poor cycle stability and fast capacity decay, achieve improved cycle performance, increased rate performance, and simple and easy preparation process line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

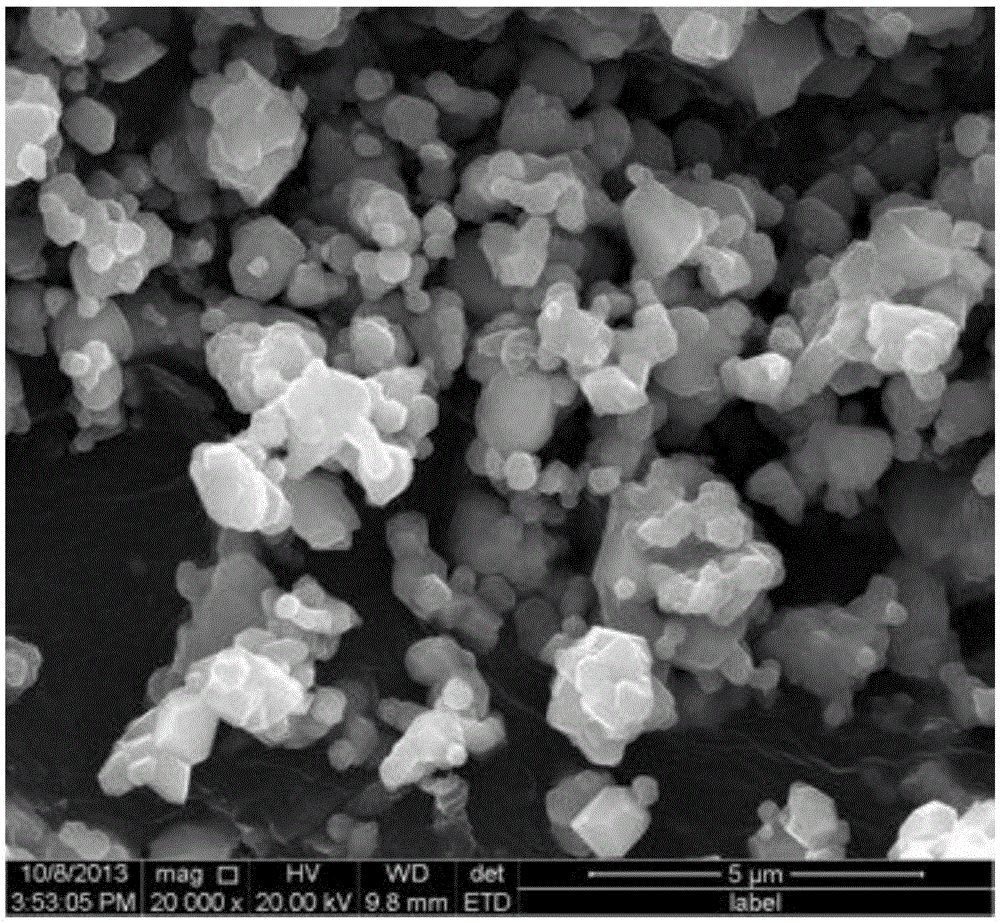

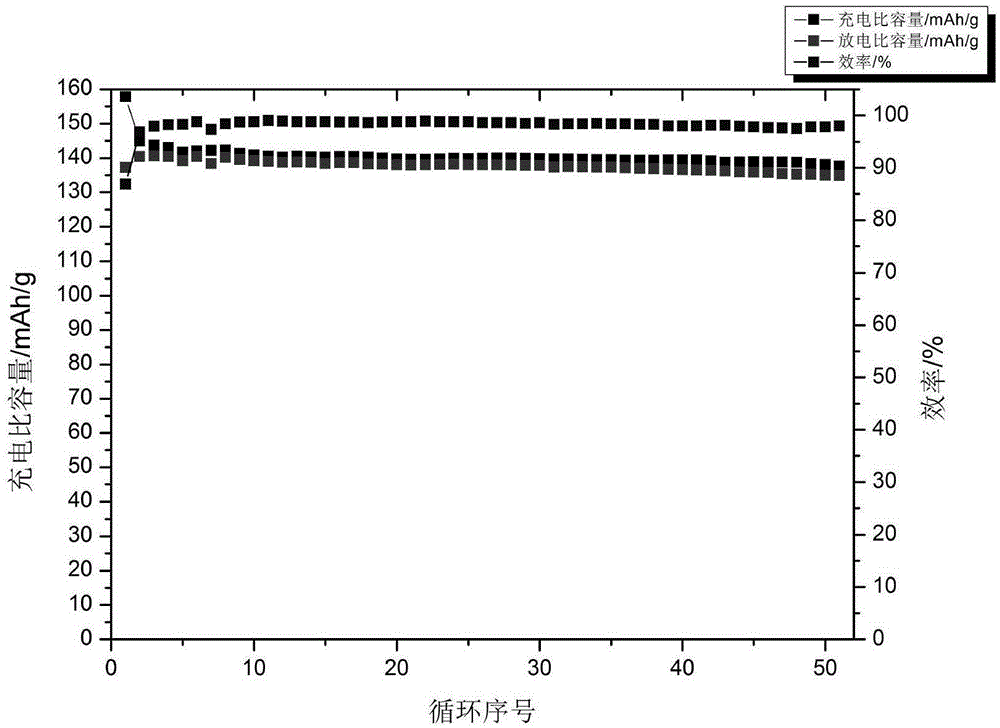

[0025] A method for preparing LiNi battery 0.5 Mn 1.5 O 4 The method of cathode material, the specific steps are:

[0026] 1) According to the stoichiometric ratio Li:Ni:Mn=1.05:0.5:1.5 (the excess lithium of 5% is to supplement the lithium element lost during high temperature calcination), weigh the target product as 2g of Ni(CH 3 COO) 2 ·4H 2 O, LiCH 3 COO·2H 2 O and Mn(CH 3 COO) 2 ·4H 2 O, mix and fully dissolve in 10ml deionized water, place it on a magnetic stirrer and stir at a constant speed until it is completely mixed.

[0027] 2) Weigh citric acid with a molar ratio of 1:1 to metal ions, dissolve it in 5ml of deionized water, add 3ml of liquid PEG400 to it, and place it on a magnetic stirrer and stir at a constant speed until fully mixed.

[0028] 3) Use a peristaltic pump to drop the mixture obtained in step 2) into the metal salt mixture prepared in step 1) at a rate of 0.3 ml / min. After stirring for 1 hour at a constant temperature of 50°C, the temperature was raised to ...

Embodiment 2

[0034] A method for preparing LiNi battery 0.5 Mn 1.5 O 4 The method of cathode material, the specific steps are:

[0035] 1) According to the stoichiometric ratio Li:Ni:Mn=1.05:0.5:1.5 (the excess lithium of 5% is to supplement the lithium element lost during high-temperature calcination), weigh the target product as 2g of LiOH, Ni(CH 3 COO) 2 ·4H 2 O and Mn(CH 3 COO) 2 ·4H 2 O, mix and fully dissolve in 10ml deionized water, place it on a magnetic stirrer and stir at a constant speed until it is completely mixed.

[0036] 2) Weigh citric acid with a molar ratio of 0.5:1 to metal ions, dissolve it in 5ml of deionized water, add 0.5g of PEG4000 to it, and place it on a magnetic stirrer and stir at a constant speed until fully mixed.

[0037] 3) Use a peristaltic pump to drop the mixture obtained in step 2) into the metal salt mixture prepared in step 1) at a rate of 0.5 ml / min. After stirring for 1 hour at a constant temperature of 50°C, the temperature was raised to 80°C to obtain a...

Embodiment 3

[0043] A method for preparing LiNi battery 0.5 Mn 1.5 O 4 The method of cathode material, the specific steps are:

[0044] 1) According to the stoichiometric ratio Li:Ni:Mn=1.05:0.5:1.5 (the lithium excess 5% is to supplement the lithium element lost during high temperature calcination), weigh the target product as 2g of Li 2 CO 3 , NiCO 3 , And MnCO 3 , Mix and fully dissolve in 10ml deionized water, place it on a magnetic stirrer and stir at a constant speed until it is completely mixed.

[0045] 2) Weigh citric acid with a molar ratio of 1.5:1 to metal ions, dissolve it in 5ml of deionized water, add 0.5g of CTAB to it, and place it on a magnetic stirrer and stir at a constant speed until fully mixed.

[0046] 3) Use a peristaltic pump to drop the mixture obtained in step 2) into the metal salt mixture prepared in step 1) at a rate of 0.3 ml / min. After stirring for 1 hour at a constant temperature of 50°C, the temperature was raised to 80°C to obtain a green fluffy floc.

[0047] 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com