Method for manufacturing lithium ion secondary battery

一种制造方法、二次电池的技术,应用在二次电池、电解质蓄电池制造、电极制造等方向,能够解决干燥设备尺寸增大、生产效率降低、浪费蒸发的溶剂本身以及干燥能量等问题,达到设备成本和安装空间减小、减少浪费、液体保持能力低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

[0055]

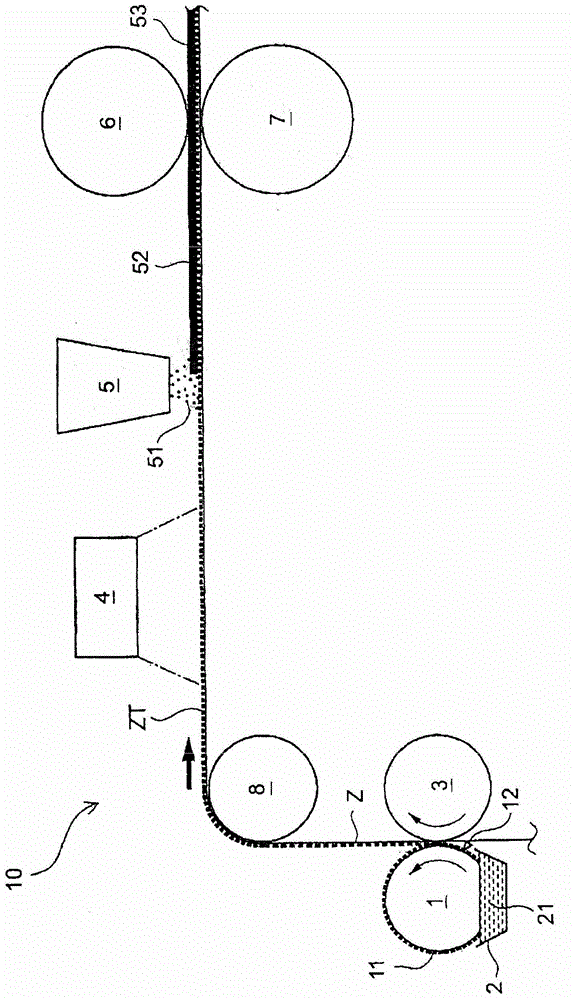

[0056] A method of forming a mixture layer on one surface of a current collector, which is a specific technical feature of and included in the method of manufacturing a lithium ion secondary battery according to the first embodiment, will be explained below. image 3 A part of the apparatus for manufacturing a lithium ion secondary battery according to the first embodiment is shown.

[0057] Such as image 3 As shown, the apparatus 10 for manufacturing a lithium ion secondary battery according to the first embodiment includes an intaglio gravure roll 1, a liquid pool 2, a back-up roll 3, a radiator 4, a powder feeder 5, pressure rolls 6, 7 And delivery roller 8. The intaglio gravure roll 1 is a cylindrical roll that applies a binder coating liquid 21 on the surface of the current collector Z in a patterned manner. The current collector Z has a thickness of about 20 μm. Intaglios 11 engraved according to a predetermined pattern shape are formed on the outer periph...

no. 2 example )

[0091]

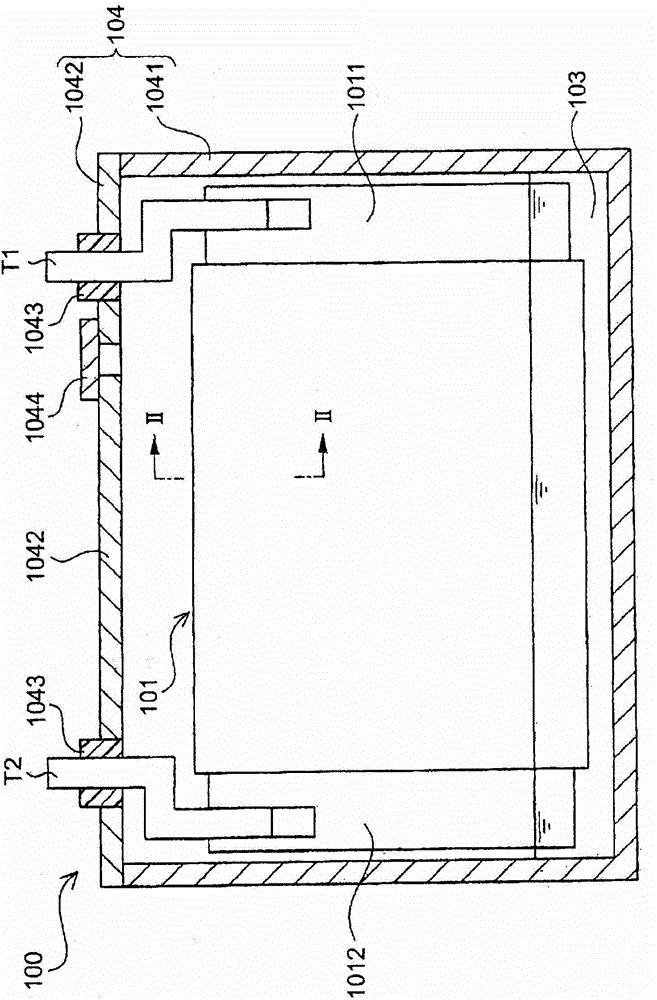

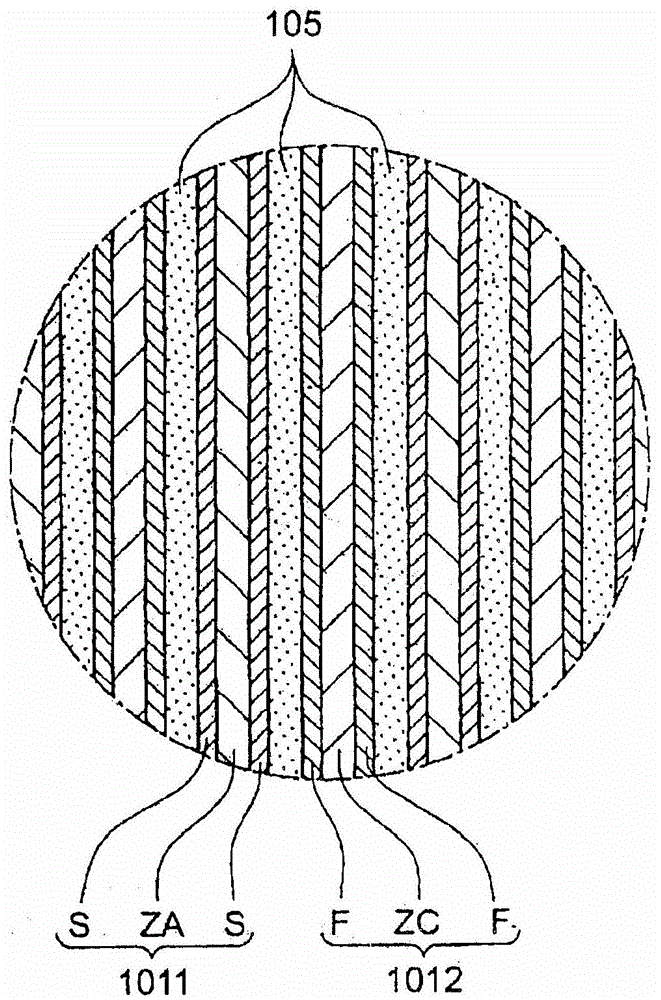

[0092] A method of forming a mixture layer on both surfaces of a current collector, which is a specific technical feature of and included in the method of manufacturing a lithium ion secondary battery according to the second embodiment, will be explained below. Figure 9 A part of an apparatus for manufacturing a lithium ion secondary battery according to a second embodiment is shown. The manufacturing method of the lithium ion battery according to the second embodiment is similar to that of the first embodiment except for features related to the method for forming the mixture layer on both surfaces of the current collector, such as the pattern shape of the intaglio intaglio Examples of manufacturing methods. A detailed description is omitted here.

[0093] Such as Figure 9 As shown, the apparatus 20 for manufacturing a lithium ion secondary battery according to the second embodiment has: a first intaglio gravure roll 1B1, a second intaglio gravure roll 1B2, a fi...

no. 3 example )

[0099] An adhesive coating process is explained below as a third embodiment in which an intaglio gravure roll to be used in intaglio gravure coating is engraved with groove-like recesses having intersections at which Where the grooves intersect each other, the binder coating liquid supplied to the groove-shaped recesses shrinks to the intersections, and forms dot-shaped coating portions on the collector. Figure 10 is a schematic diagram showing how an intaglio roll is engraved with dot-like recesses and how a binder coating liquid is applied on a collector. Figure 11 is a cross-sectional view illustrating the contact angle of a liquid droplet when the liquid is dropped on a solid surface. Figures 12A-12D is a schematic diagram illustrating how an adhesive coating liquid in a groove-like recess having intersections where the grooves intersect each other is shrunk toward the intersections. Figure 13 is a plan view of the groove-shaped recess according to the third embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com