Anti-tension triple-connected middle string clamp for 1,000kV ultrahigh-voltage power transmission line

A transmission line and ultra-high voltage technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of large structure size of shielding pressure equalizing ring and large space occupied by triple series

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The utility model relates to a replacement jig for tension-resistant triple series insulators of 1000kV UHV transmission lines, which is suitable for replacing the first insulator at the cross-arm end of the triple series and the first insulator at the conductor end. The specific operation method is as follows:

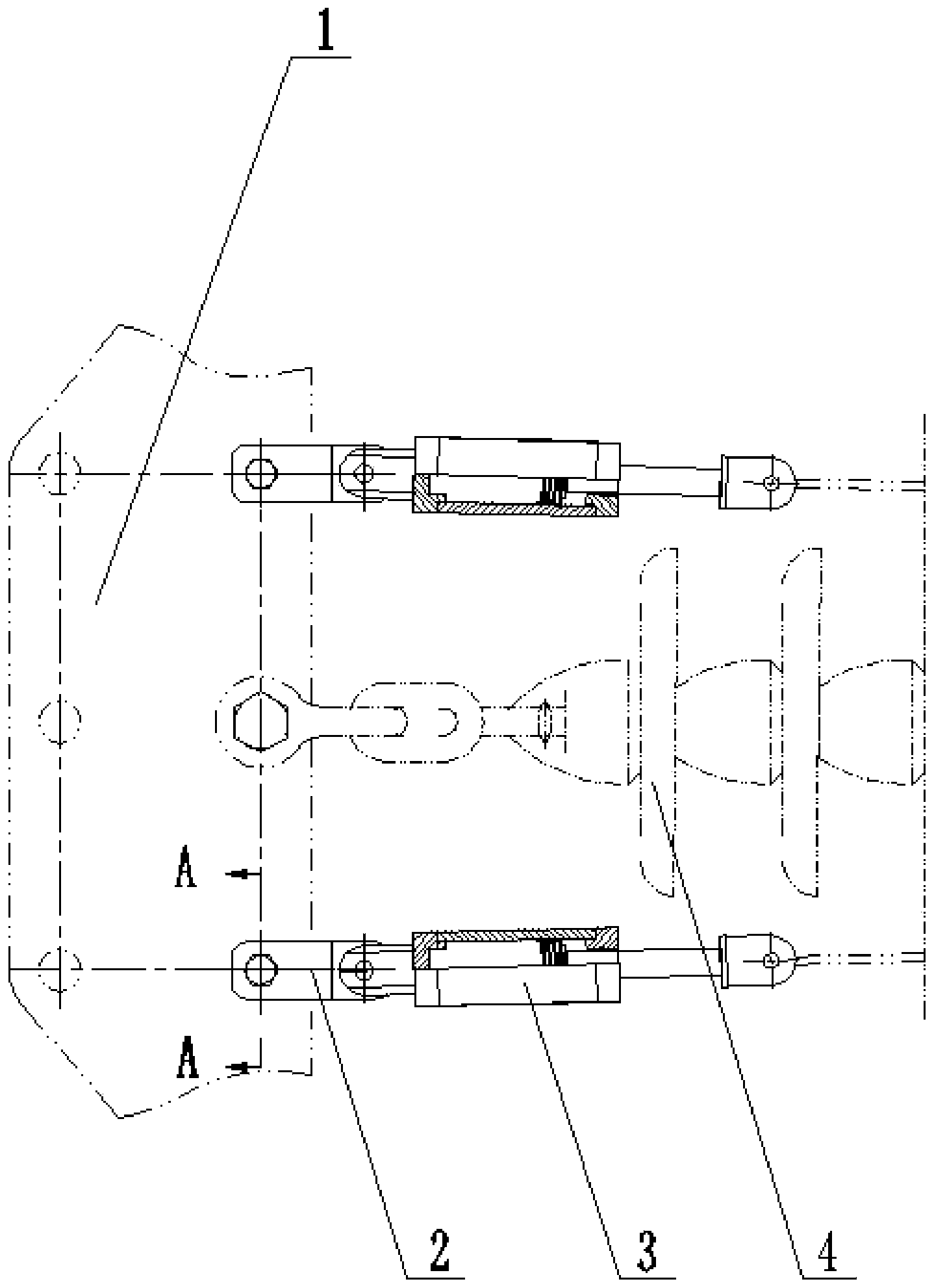

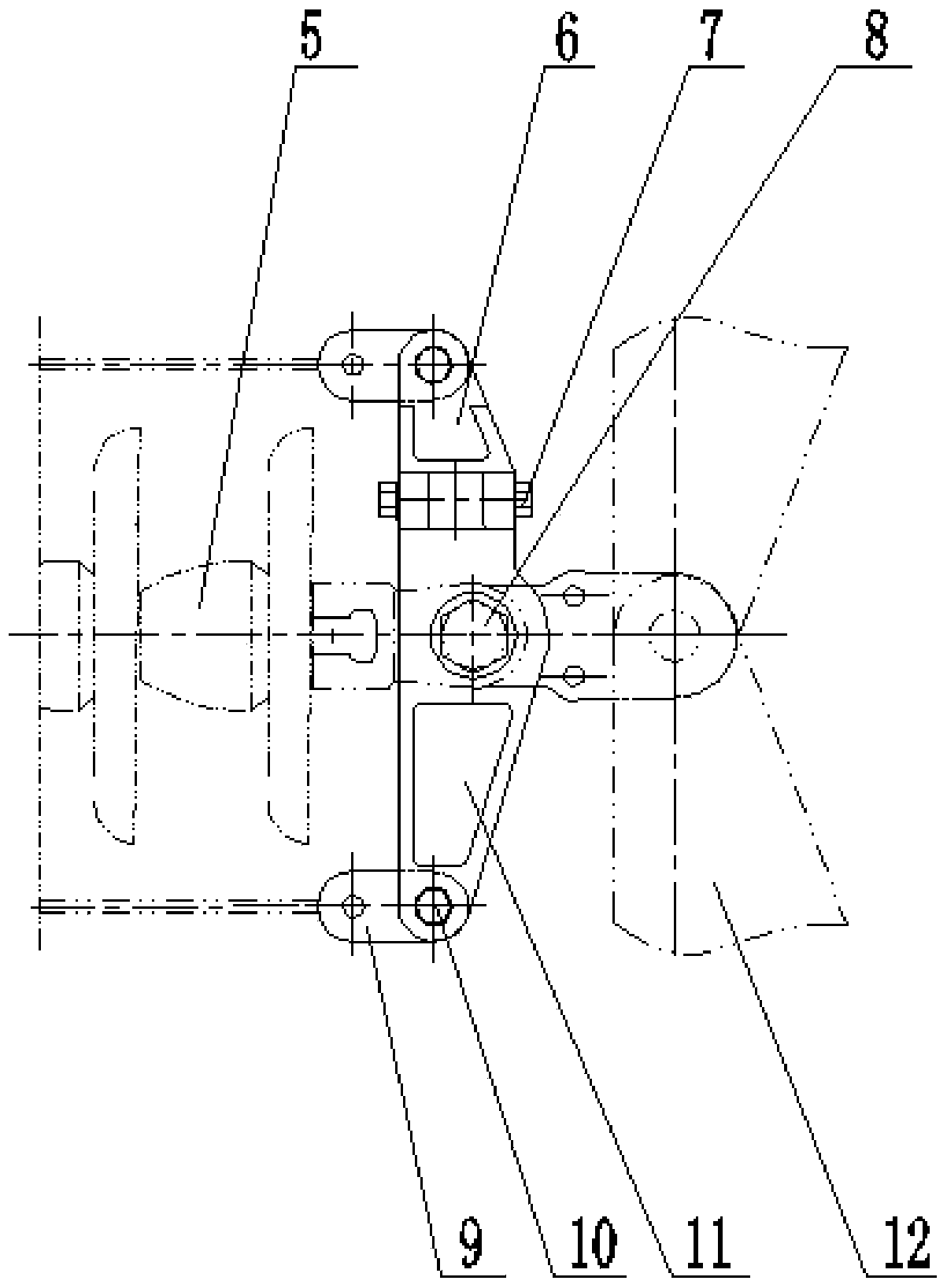

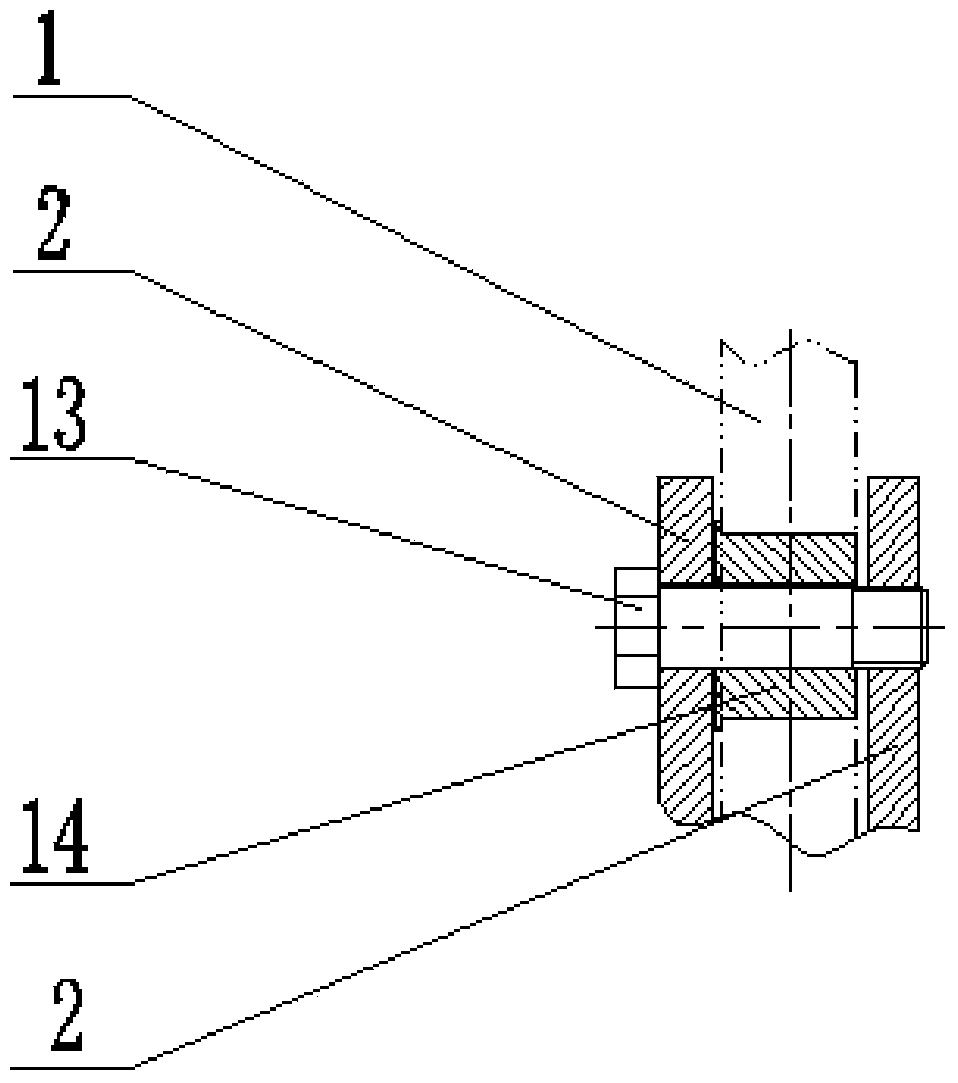

[0020] Replace the first piece of insulator at the cross-arm end such as figure 1 Shown: Use cross-arm end clamp 2 to connect hydraulic screw 3 and closed clamp front clamp (closed clamp front clamp is in figure 1 not marked in) implementation. During operation, the other ends of the upper and lower cross-arm end clips 2 are respectively installed on the construction holes of the three-connected series plate 1 through connecting pins 15 and pin sleeves 14 ( image 3 ). Arrange the cross-arm end cards 2 on both sides of the middle string insulator 5 . The other end of the clamp 2 at the end of the cross arm is connected to the bottom end of the hydraulic scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com