Method and device for improving flexibility of loudspeaker driver

A driver and speaker technology, applied in the direction of sensors, electrical components, etc., can solve the problems of unfavorable production, low sensitivity, and complicated structure of the equalizer, and achieve the effect of increasing power, enhancing sensitivity, and improving sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

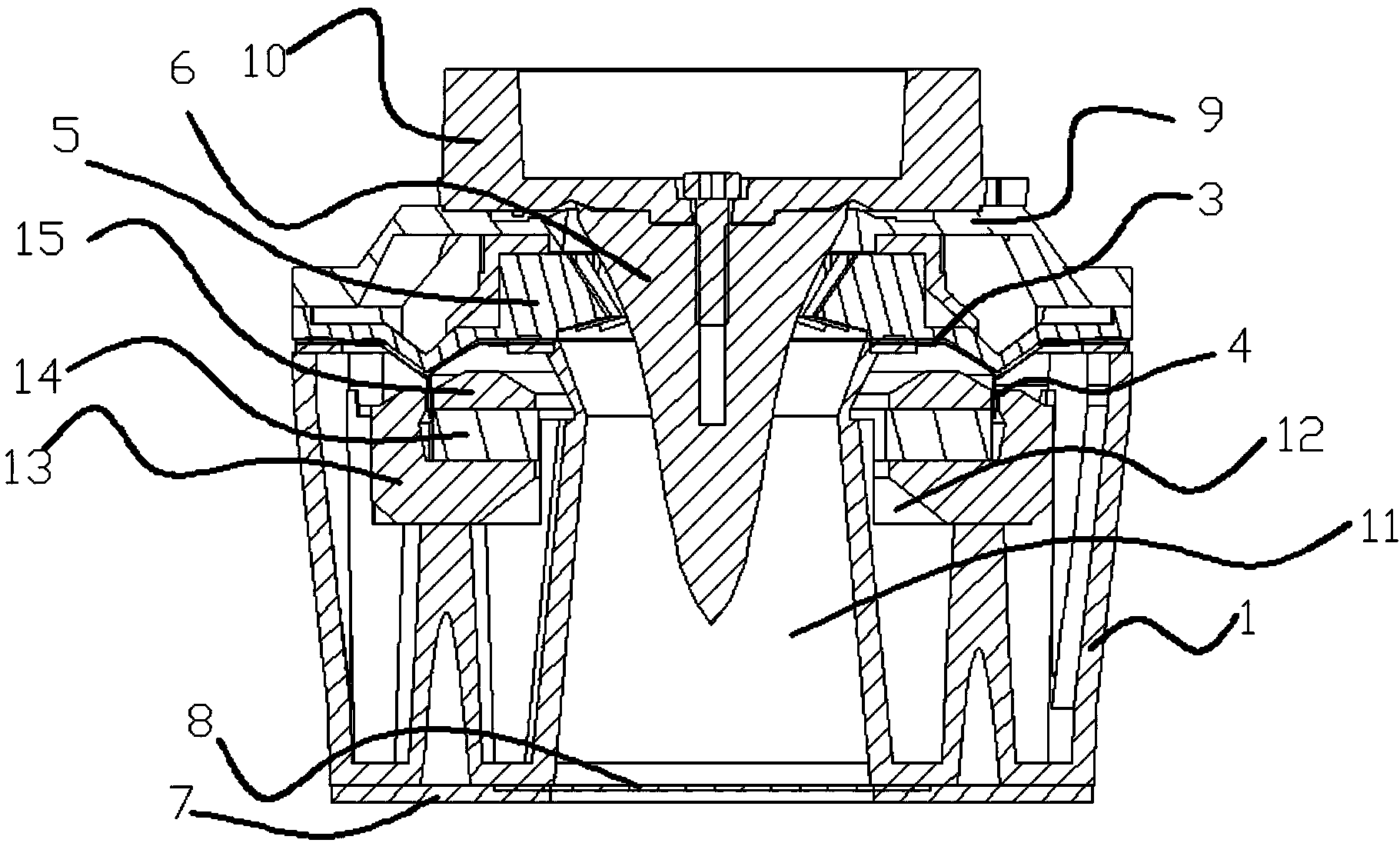

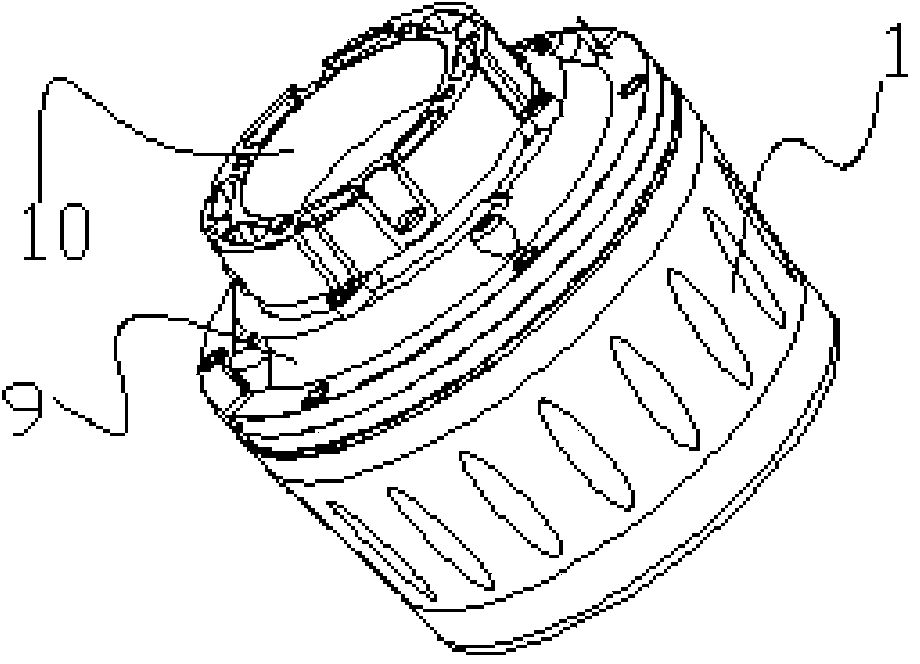

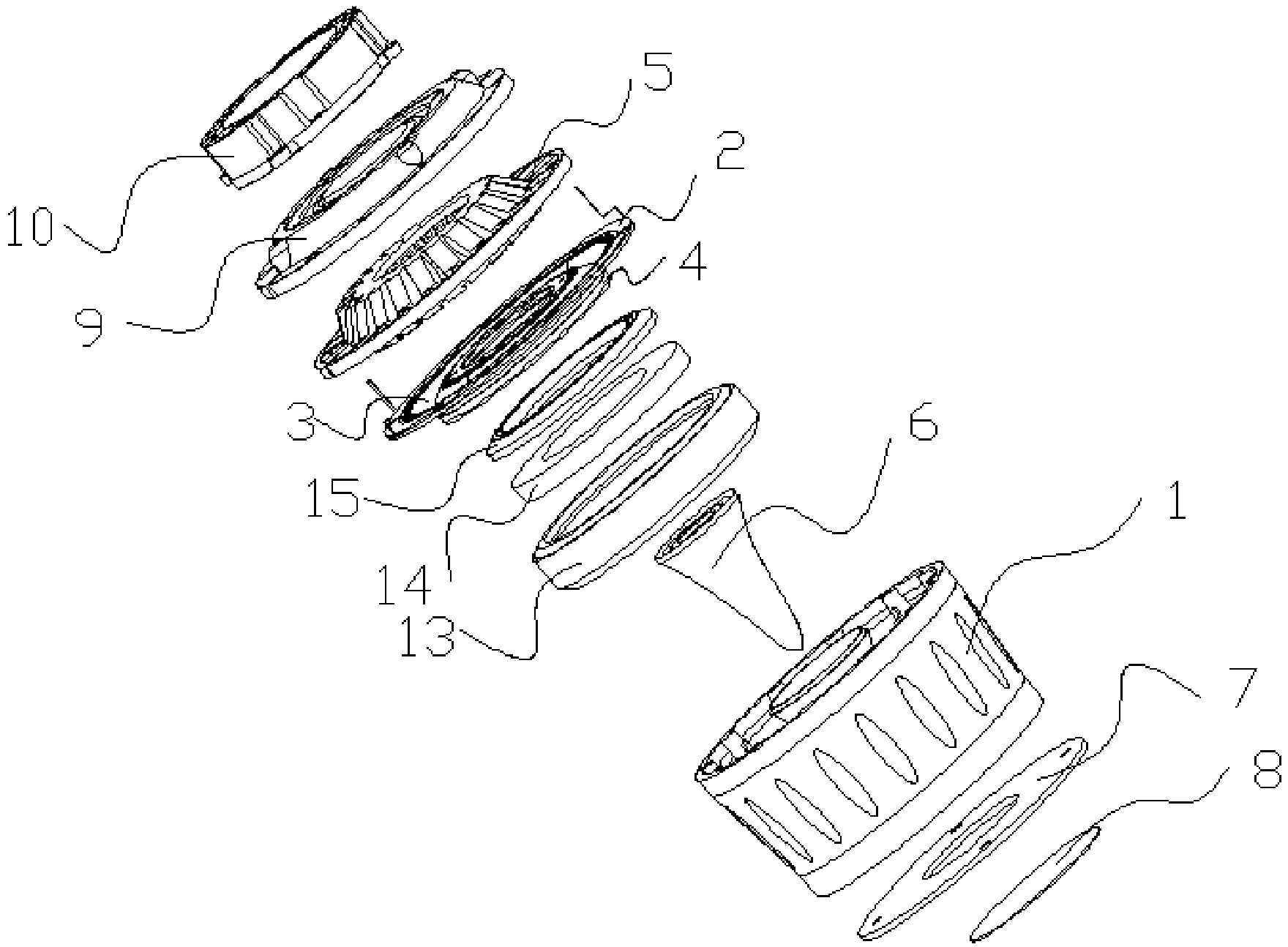

[0046] see Figure 1 to Figure 5 , a kind of method for improving the sensitivity of loudspeaker driver provided by the present invention, it specifically comprises the following steps:

[0047] (1) a tweeter cylinder body 1 is set;

[0048] (2) A pot frame 2, a magnetic circuit system, a diaphragm 3 and a voice coil 4 combined with the pot frame 2 are set, the upper end of the voice coil 4 is fixed to the diaphragm 3, and the lower end penetrates into the magnetic circuit system. In the gap; the basin frame 2 is arranged at the opening of the treble cylinder body 1, and the magnetic circuit system is arranged inside the treble cylinder body 1;

[0049] (3) An equalizer assembly is set, which includes a compression-type equalizer structure 5 and a diffusion-type equalizer structure 6, and the compression-type equalizer structure 5 is connected to the basin frame 2, and the described The diffusion equalizer structure 6 is arranged inside the treble cylinder body 1;

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com