Solar cell and method for manufacturing the same

A solar cell and back electrode layer technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of reducing solar cell efficiency and increasing contact resistance, so as to increase electron collection efficiency and reduce Effects of improving contact resistance and current characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments will be described in more detail below with reference to the accompanying drawings.

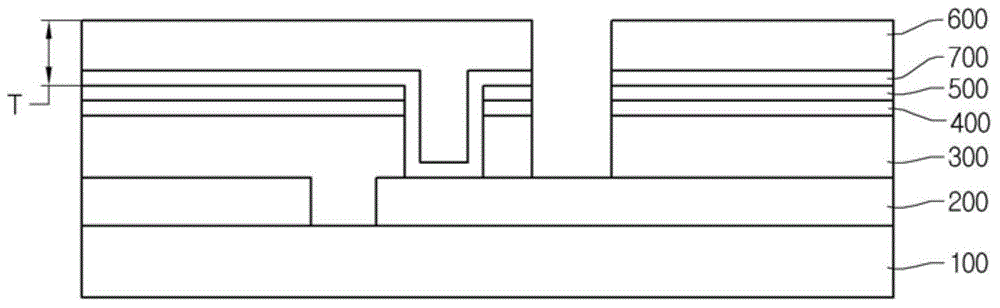

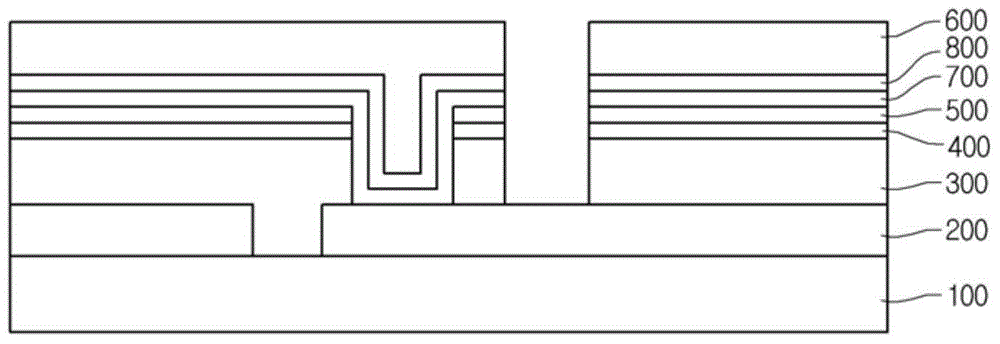

[0018] figure 1 is a sectional view showing a solar cell according to an embodiment, and figure 2 is a cross-sectional view showing a modified example of the solar cell according to the embodiment.

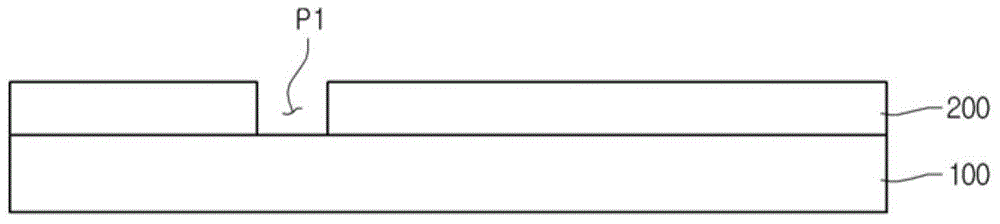

[0019] see figure 1 , The solar cell according to the embodiment includes a substrate 100, a back electrode layer 200 on the substrate 100, a light absorbing layer 300 on the back electrode layer 200, a first buffer layer 400 and a second buffer layer on the light absorbing layer 300 500 , the transparent electrode layer 600 on the second buffer layer 500 and the impurity doped layer 700 between the light absorbing layer 300 and the transparent electrode layer 600 .

[0020] The substrate 100 may have a flat plate shape and include a transparent glass material.

[0021] Substrate 100 may be rigid or flexible. Besides a glass substrate, a plastic substrate or a metal subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com