Main motors for railway vehicles

A technology for main motors and railway vehicles, applied in AC motor control, electric motors, electric vehicles, etc., can solve problems such as main motor loss, achieve the effects of reducing low-order harmonic components, suppressing circulating current, and suppressing switching losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

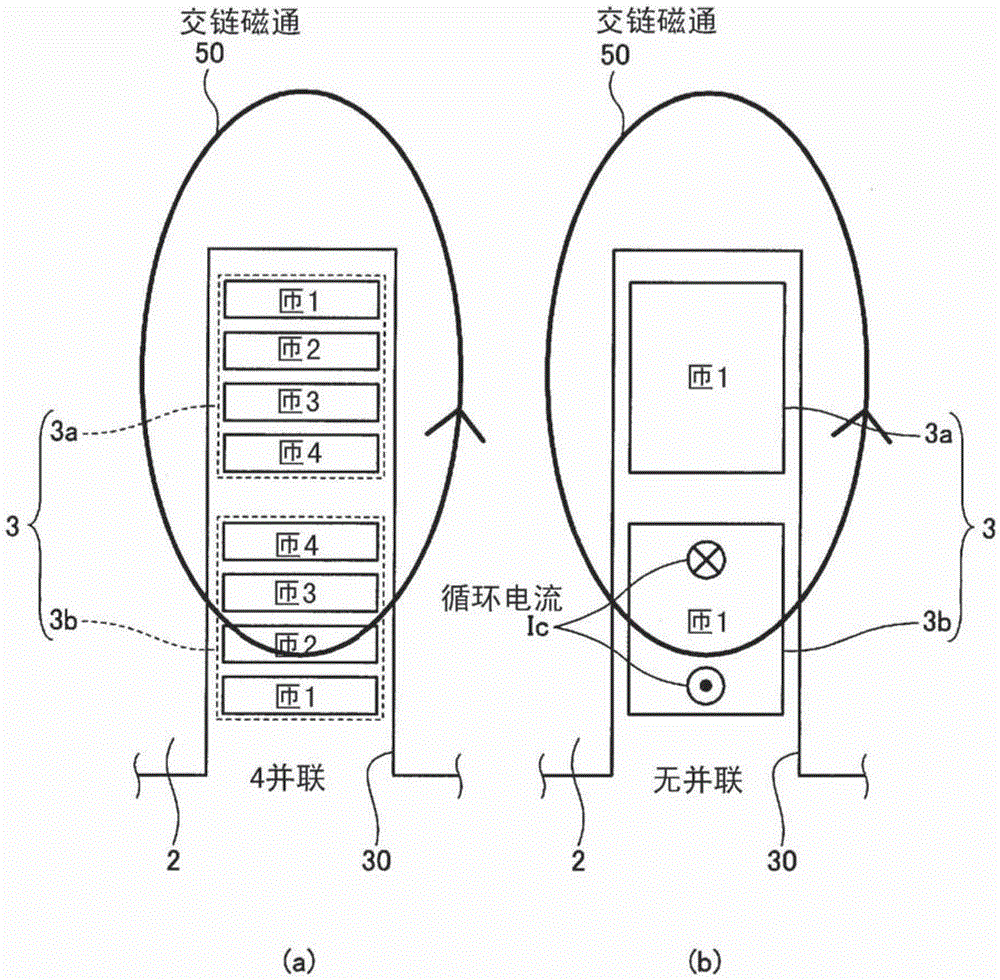

Problems solved by technology

Method used

Image

Examples

Embodiment approach

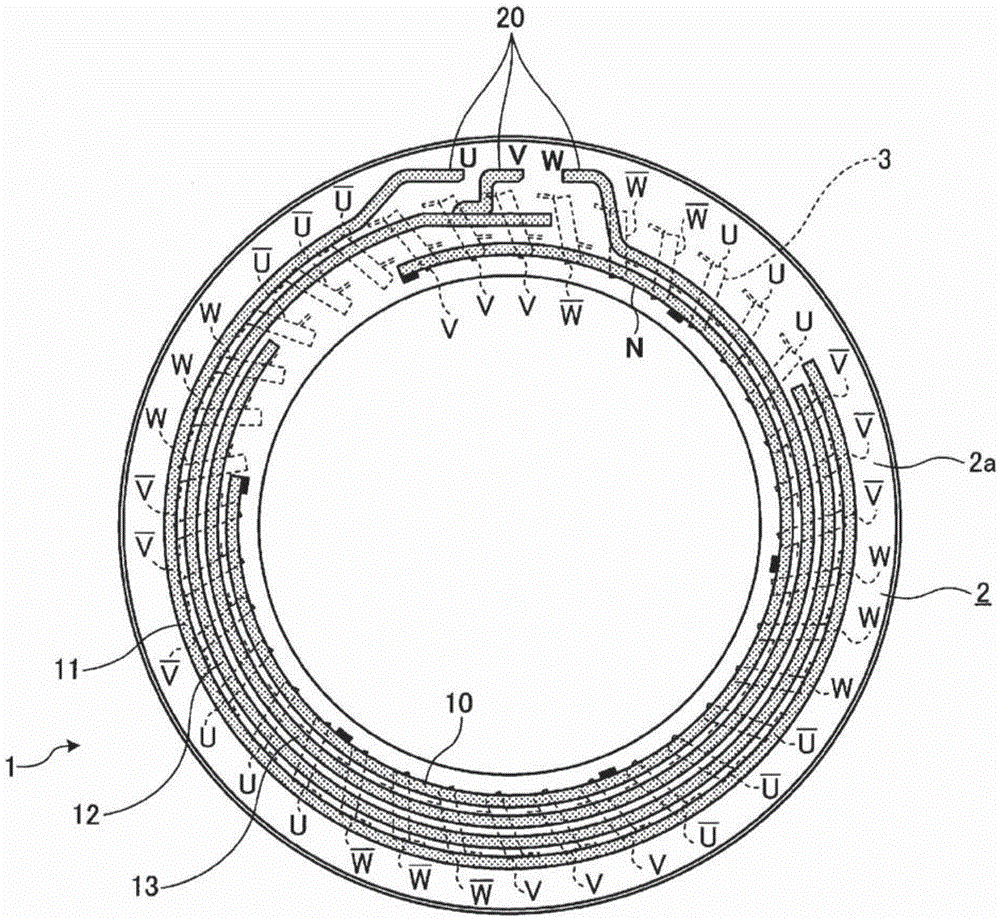

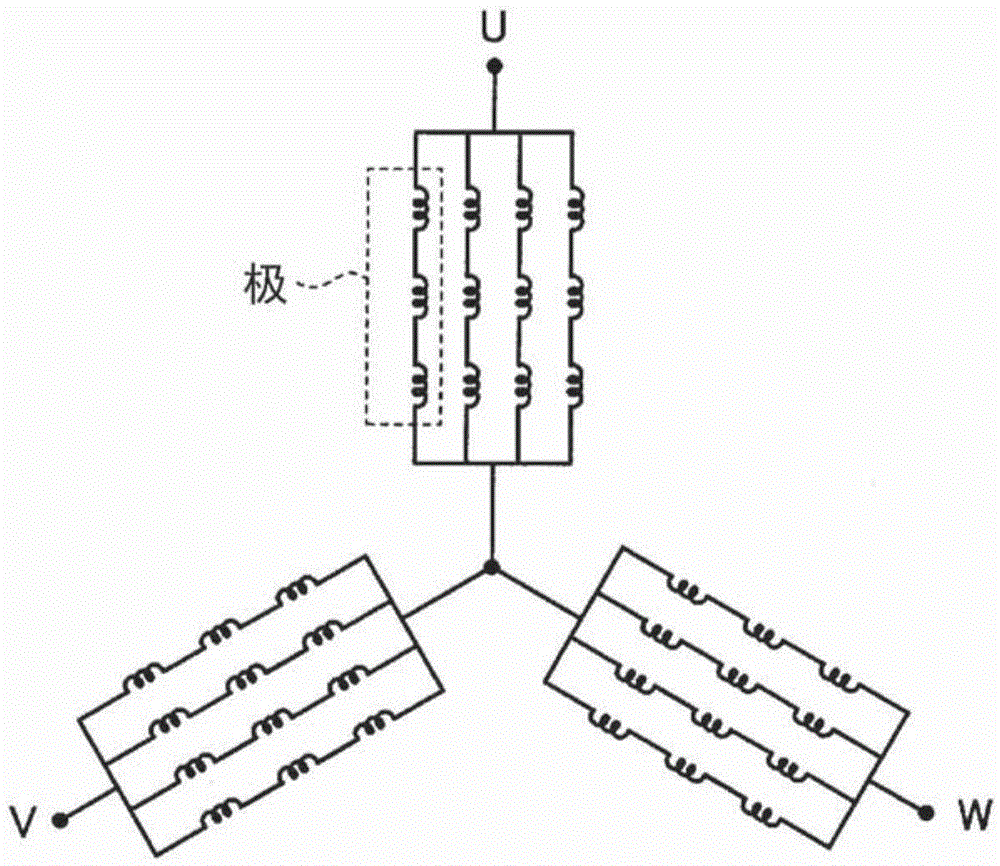

[0030] The main electric motor for railway vehicles (hereinafter simply referred to as "main electric motor") according to the present invention is an electric motor mounted on an electric train for driving a vehicle. The main motor is a three-phase AC motor, such as an induction motor. However, as long as the main motor has the same structure as the stator described below, it may be other than the induction motor, for example, may be a synchronous motor.

[0031] In electric vehicles, the inverter circuit usually converts the electric power collected by the overhead line into three-phase alternating current, and supplies the alternating current to the main motor. Here, when the trolley line is a DC trolley line, the DC power supplied from the trolley line is converted into AC power with variable voltage and variable frequency by an inverter circuit, and the AC power is supplied to the main motor. When the overhead line is an AC overhead line, the rectifier circuit is used to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap