Metal winding gasket outer ring lathe groove chuck

A metal winding and outer ring technology, applied in the direction of the chuck, etc., can solve the problems such as the inability to guarantee the machining accuracy, the inability to reliably clamp the parts, and the distortion and deformation, and achieve the effects of simple structure, reliable clamping and increased contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

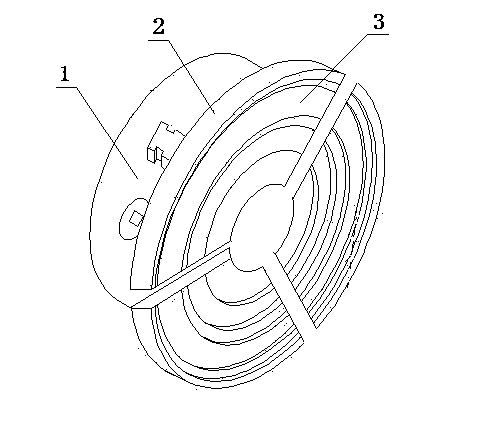

[0015] Such as figure 1 As shown, a metal winding pad outer ring groove chuck is composed of a three-jaw chuck 1 and a fan-shaped claw 2, and there are three fan-shaped claws 2, which are respectively fixed on the three claws of the three-jaw chuck 1; Each fan-shaped claw 2 forms a hollow ring shape with a gap of 8-13mm; the fan-shaped claw 2 has circular arc steps 3 that descend successively when getting on the car; the number of circular arc steps 3 is 10-15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com