Profile Shearing Device

A shearing device and profile technology, applied in shearing devices, accessories of shearing machines, shearing machine equipment, etc., can solve the problems of high work intensity of workers, long production line adjustment cycle, waste of materials, etc., and achieve section quality. High, good use value, less burr effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

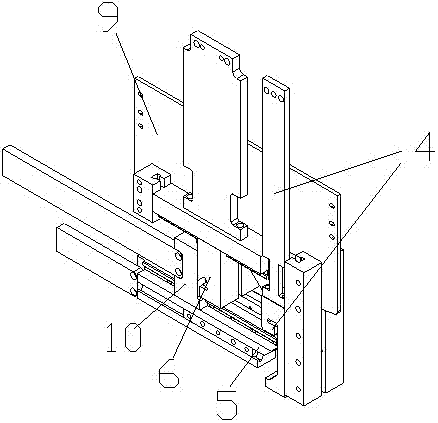

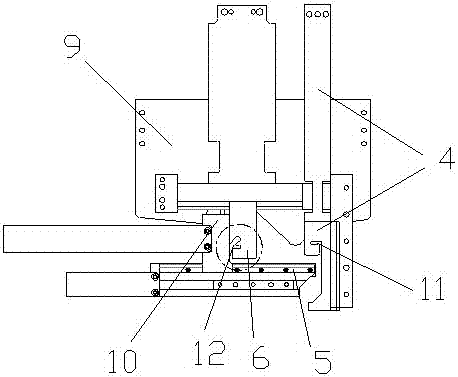

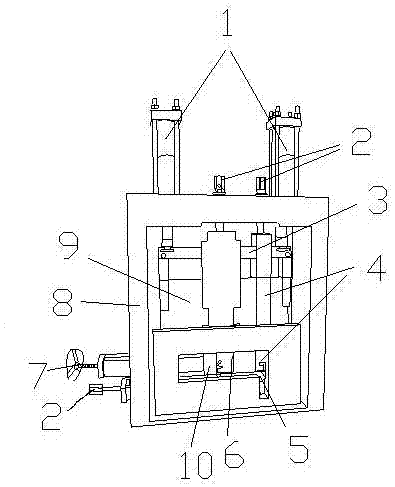

[0023] Referring to illustrations 1 to 7, a profile shearing device includes a blade 9, a front die adjustment mechanism and a rear die adjustment mechanism, and the front die adjustment mechanism and the rear die adjustment mechanism are respectively arranged on the front and rear sides of the blade 9 , the front knife mold adjustment mechanism and the rear knife mold adjustment mechanism both include a left movable knife mold assembly and a right movable knife mold 4, and the right movable knife mold 4 is provided with a right opening 11 matching the profile, and the The left movable knife mold assembly includes a height-adjustable movable knife mold 6 that can move up and down and a width-adjustable movable kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com