Gear broaching key positioning fixture

A technology for positioning fixtures and gears, which is applied to positioning devices, clamping, broaching machines, etc., can solve the problems of inconvenient keyway processing, difficulty in ensuring the angle between keyway and teeth, and difficulty in ensuring accuracy, etc., and achieves simple use, low cost, Highly stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

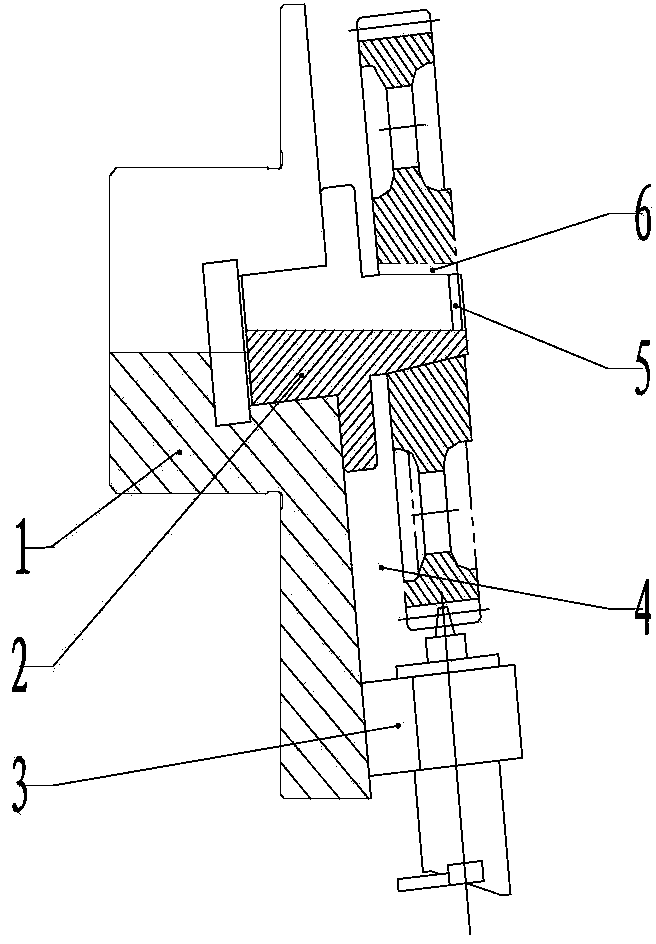

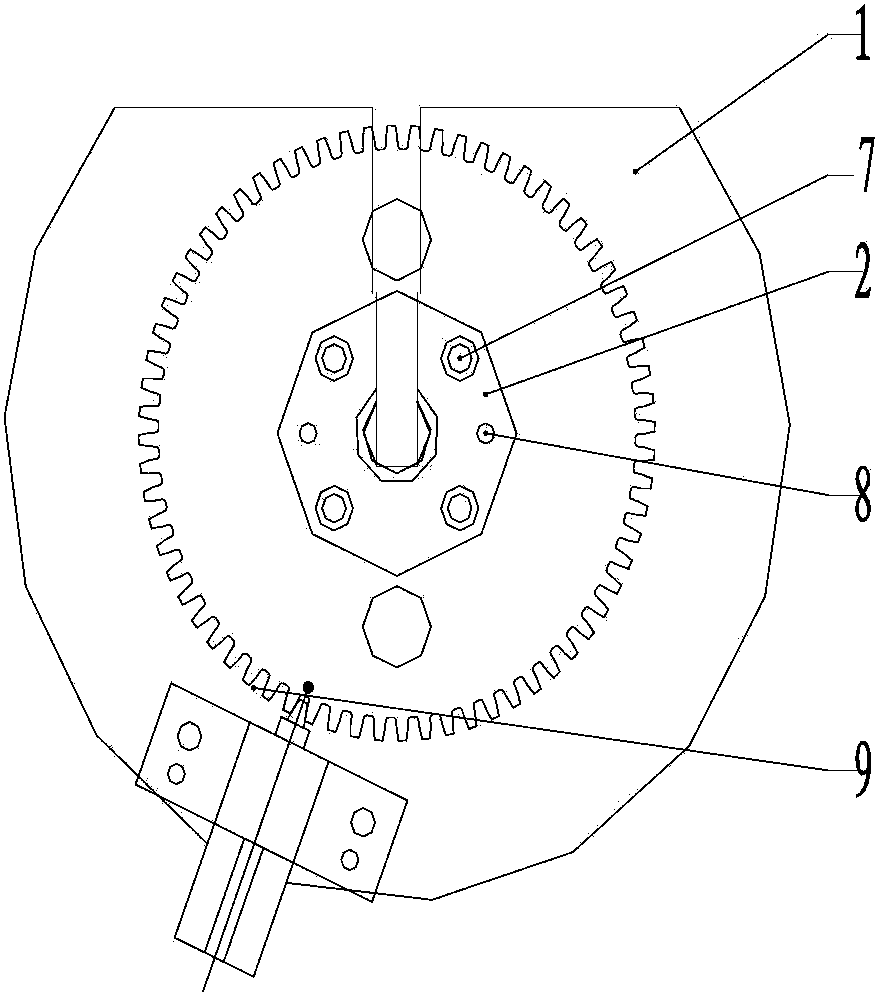

[0010] Such as figure 1 , figure 2 As shown, the gear pull key positioning fixture is composed of a clamp body 1, a guide body 2, and a positioner 3; the left end of the clamp body 1 is connected to a horizontal broaching machine, and the right end is matched with the inner hole of the gear 4 through the mandrel of the guide body 2; the guide body 2 is composed of The screw 7 and the positioning pin 8 are connected and clamped on the clamp body 1 ; The positioner 3 is installed on the clamp body 1 。

[0011] Such as figure 2 As shown, according to the taper of the gear hole and the width of the keyway 6, the taper and width of the mandrel of the clamp body 1 and the guide body 2 are processed, the guide body 2 is installed into the clamp body 1, and the guide body is fixed with the screw 7 and the positioning pin 8. 2. Connect and clamp with the clamp body 1; install the locator 3 on the clamp body 1 according to the angle between the keyway 6 and the marking tooth 9 req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com