Tool special for tower assembling and welding

A pairing and tower technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as high requirements for welding skills, difficulty in ensuring the safety of staff, and height restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below according to the drawings and specific embodiments.

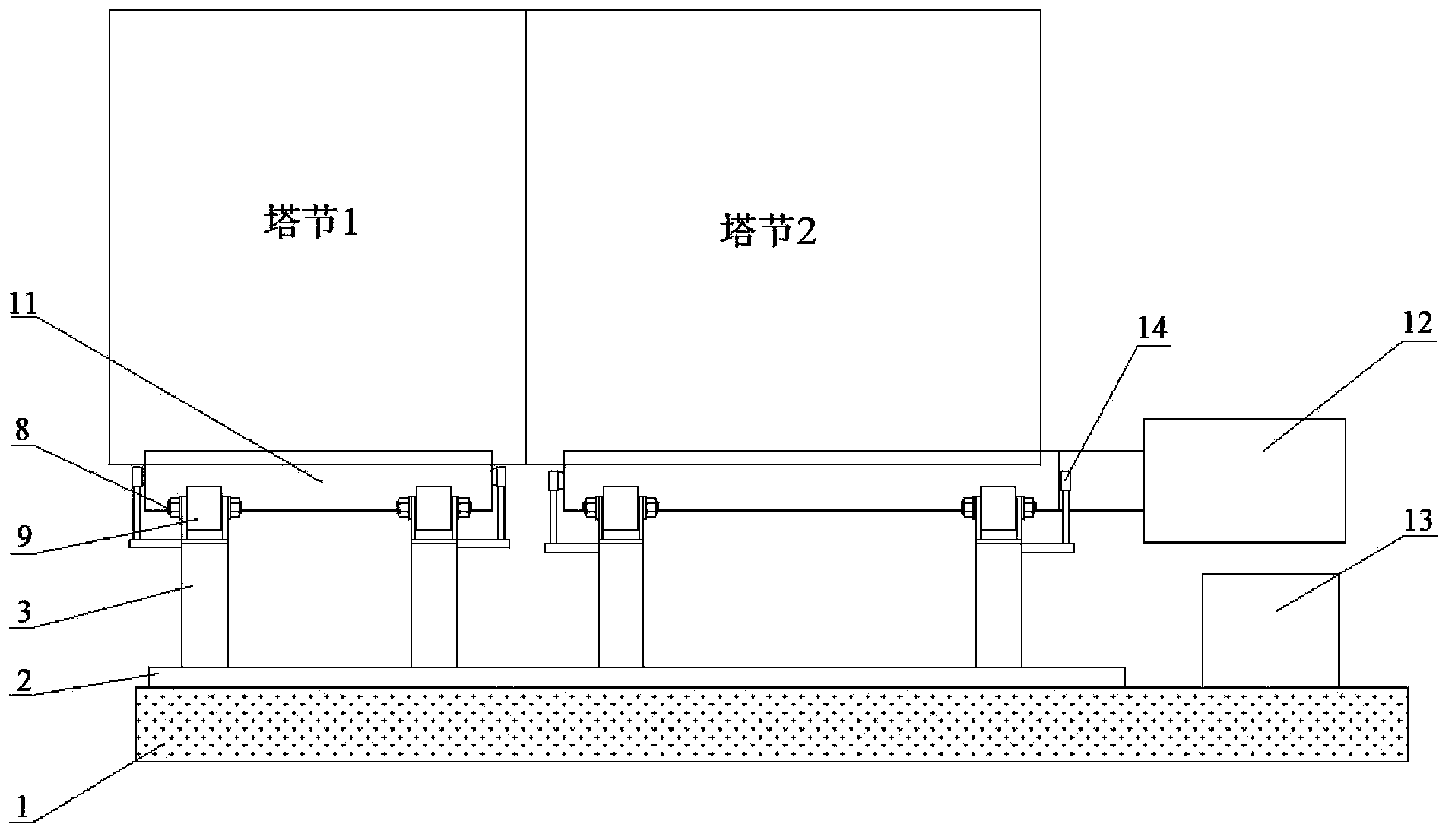

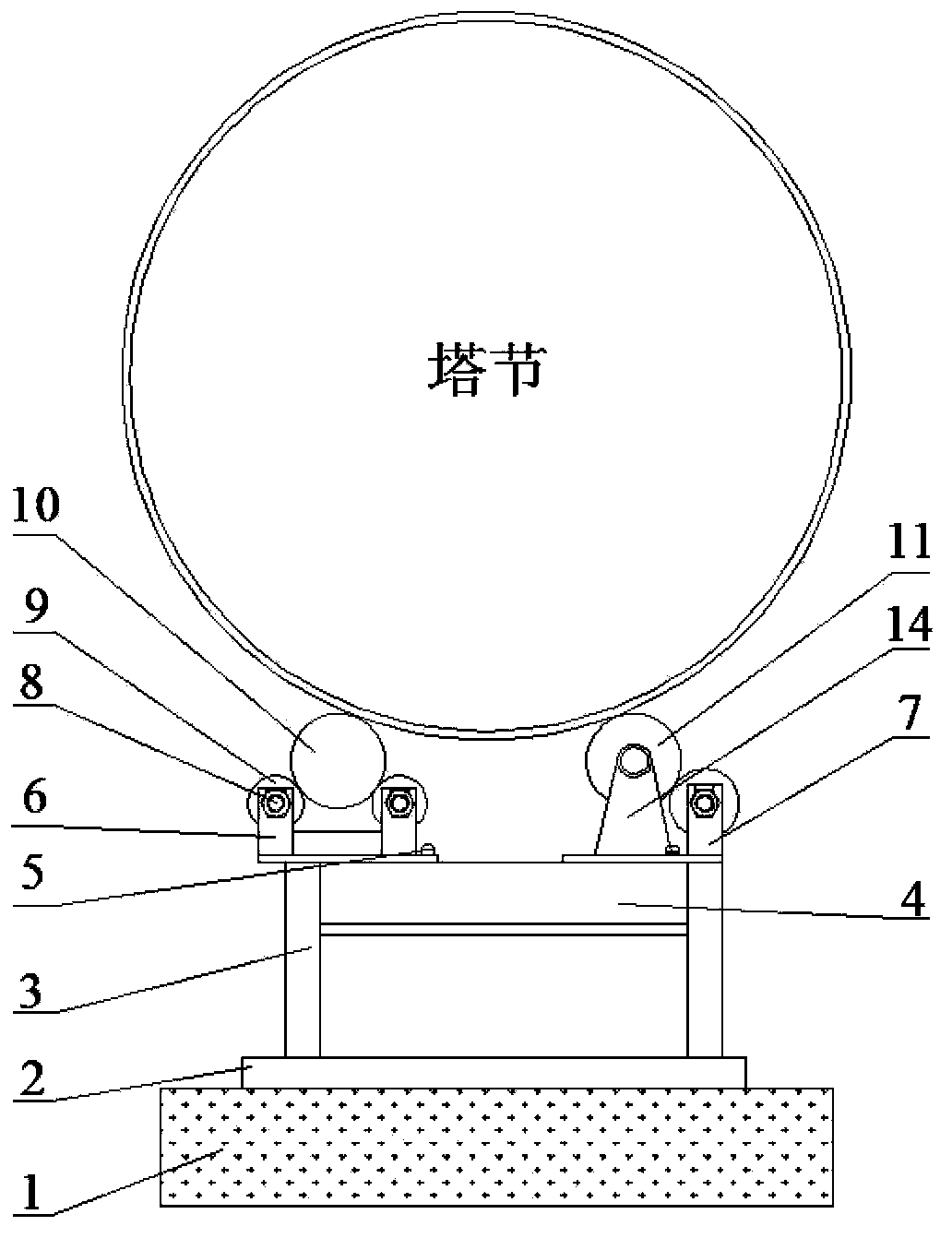

[0021] Such as figure 1 with figure 2 As shown, a special tooling for butt welding of a tower group is characterized in that it includes a base 1, a support base 2 and a control cabinet 13, and a column 3 is arranged on the support base 2, and a column 3 is arranged between the columns 3 horizontally. The roller frame base 4, the two ends of the roller frame base 4 are respectively provided with a driving roller bracket 6 and a driven roller bracket 7, and the driving roller bracket 6 and the driven roller bracket 7 are provided with guide bolts 8 fixed guides. Wheel 9, drive roller 10 is arranged between two guide wheels on the drive roller frame 6, and described drive roller 10 is connected with motor reducer 12, and the guide wheel on the driven roller frame 7 is provided with The driven roller 11, the two ends of the driven roller 11 are fixed by the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com