An intelligent edging machine with a movable grinding head group

A technology of edge grinding machine and moving mechanism, which is applied in the direction of grinding head, machine tool suitable for grinding the edge of workpiece, and parts of grinding machine tool, etc. It can solve the problems of affecting work efficiency, unstable grinding speed, grinding equipment shutdown, etc. problems, to improve work efficiency, realize automation, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

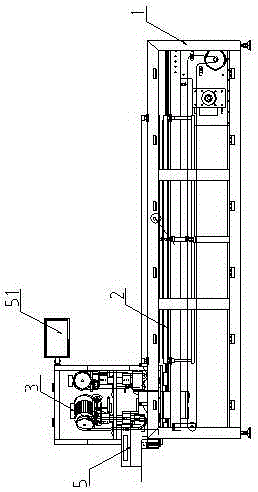

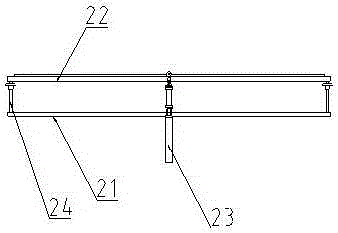

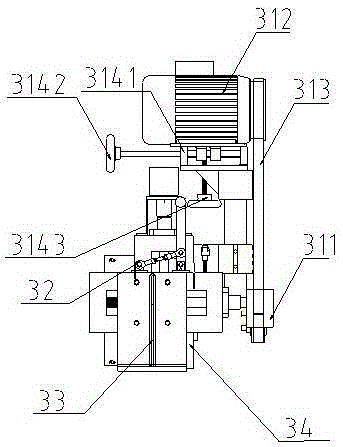

[0023] see figure 1 , figure 2 , image 3 as well as Figure 4 , as shown in the legend therein, an intelligent edging machine with a movable grinding head group is used for grinding the edge of a sandpaper workpiece, including a frame 1, an edging jig 2, a grinding head assembly 3, A moving mechanism and a PLC control system 5, the sandpaper workpiece is set on the edging jig 2; the edging jig 2 is set on the frame 1; Grinding the edge of the workpiece with sandpaper; the moving direction of the moving mechanism is the same as the grinding direction of the workpiece; the PLC control system 5 controls and connects the edging fixture 2, the grinding head assembly 3 and the moving mechanism.

[0024] The moving mechanism includes a synchronous belt 41, an active synchronous wheel 42, three passive synchronous wheels 43 and a transmission wheel servo motor 44, the transmission wheel servo motor 44 is arranged on the frame 1; the active synchronous wheel 42 is connected to the...

Embodiment 2

[0038] see Figure 1-Figure 5, as shown in the legend therein, the rest are the same as the first embodiment, the difference is that the intelligent edging machine with the movable grinding head group also includes a dust removal device, and the dust removal device includes a dust removal cover 61, an air curtain Mechanism and a dust suction device (not shown in the figure), the dust removal cover 61 is provided with an opening; The pipe 621 is provided with slits or several holes in the axial direction; the dust removal cover 61 is set on the outside of the grinding head assembly and the opening of the dust removal cover 61 is set at the grinding head 311; the air curtain tube 621 is erected on the opening of the dust removal cover 61; The air curtain formed by the air curtain pipe 621 seals the opening of the dust cover 61; the suction pipe of the dust suction device is connected to the bottom and / or side of the dust cover 61;

[0039] A large amount of dust will be produce...

Embodiment 3

[0041] The rest are the same as in the above-mentioned embodiment 2, the difference is that the intelligent edging machine with the movable grinding head group is used for grinding the back side of the sandpaper workpiece, and includes four grinding head mechanisms, and the grinding head mechanisms are arranged successively to remove the abrasive belt. Rubber rotary peripheral surface grinding, steel wire or copper wire rotary peripheral surface grinding, black gold steel rotary peripheral surface grinding and black gold steel end face grinding; the grinding head mechanism is arranged along the moving direction of the moving mechanism.

[0042] Abrasive belt degumming rotary peripheral face grinding is used to remove the adhesive strips on the back of the sandpaper workpiece; steel or copper wire rotary peripheral face grinding is used for rough grinding; black gold steel rotary peripheral face grinding is used for fine grinding and forming pile face; black gold steel end groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com