Numerical control six-roller veneer reeling machine

A technology of trigger and roll, which is applied in the field of forging machine tool equipment, can solve the problems of low degree of automation, low processing precision, and low production efficiency, and achieve the effects of reducing labor intensity, improving processing efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

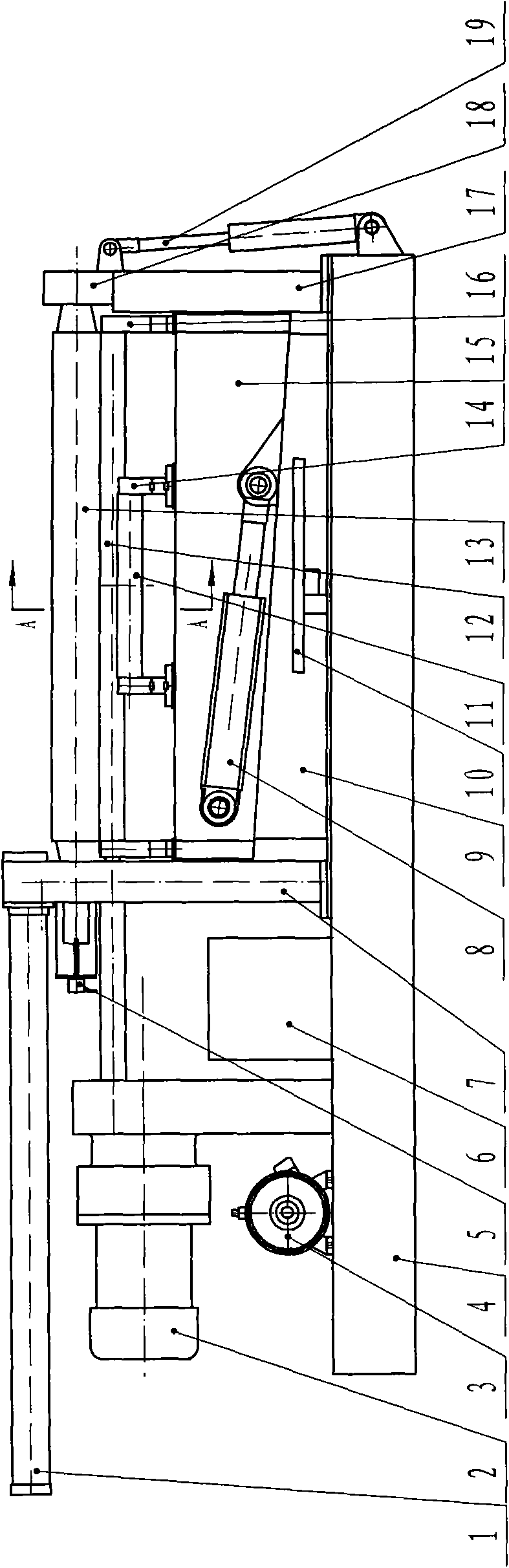

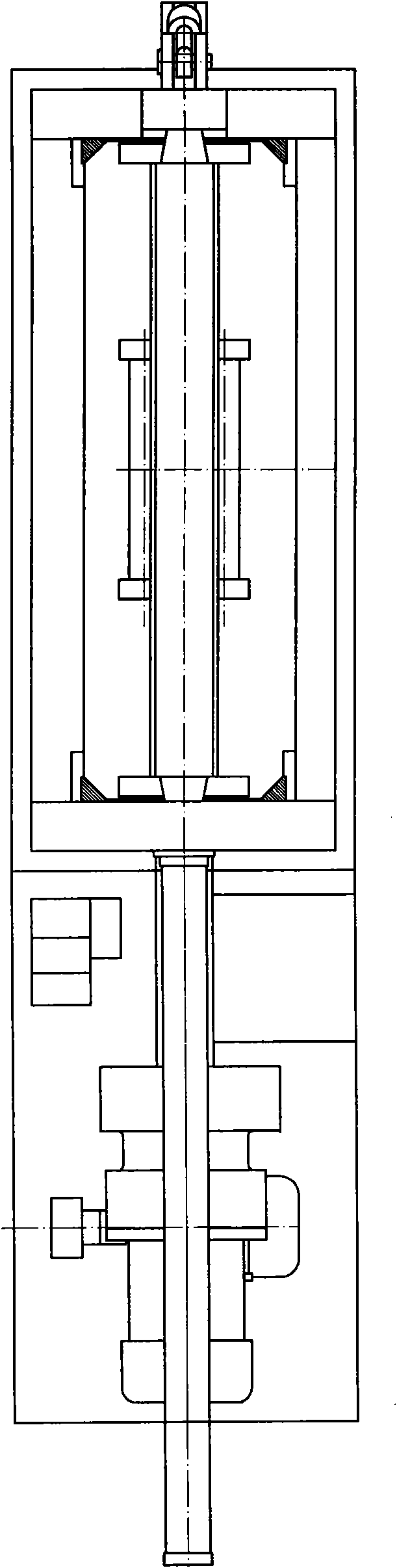

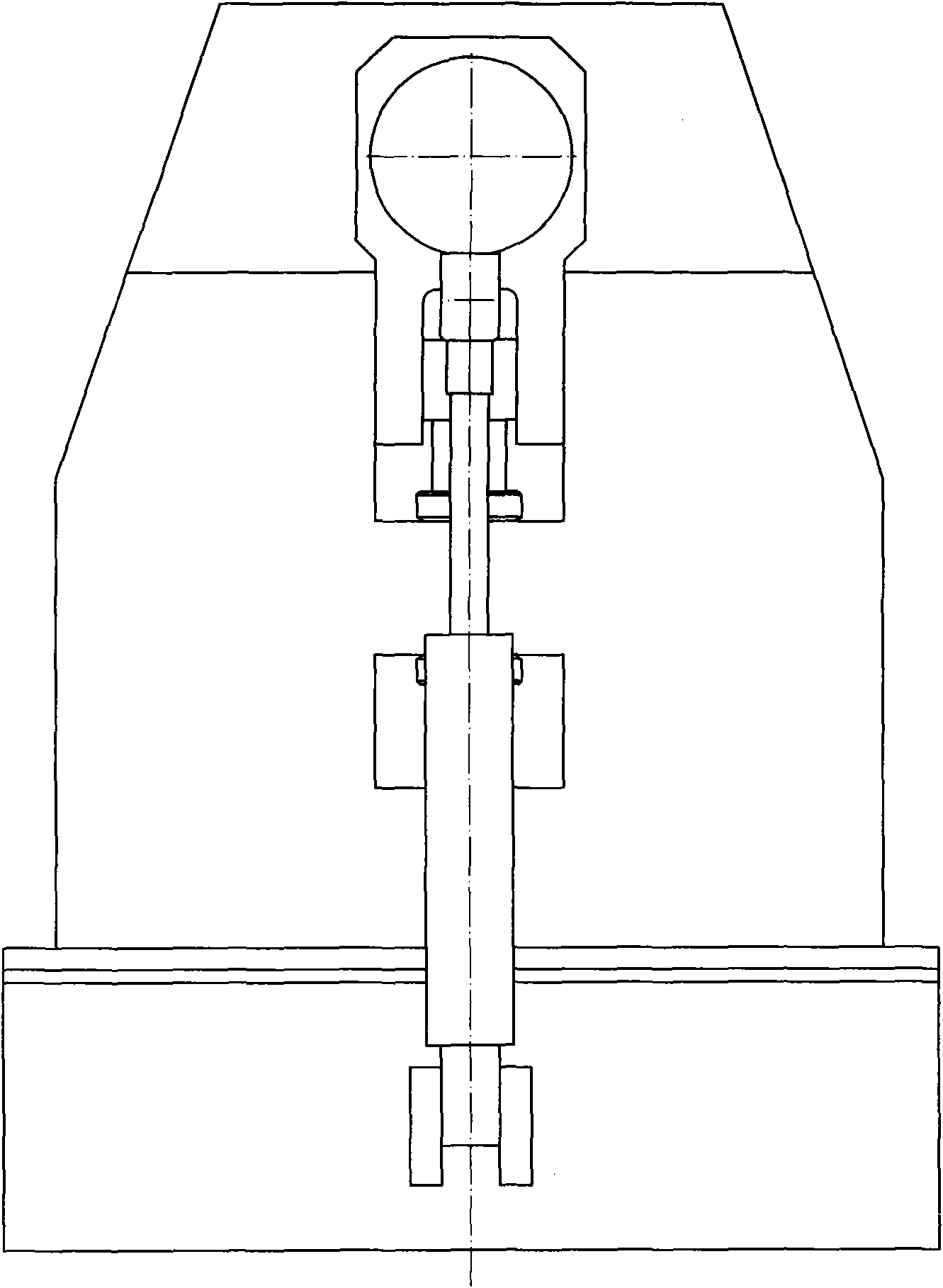

[0014] Refer to attached Figure 1-7 :

[0015] This CNC six-roll plate rolling machine is an improvement on the existing six-roll plate rolling machine. It consists of cylinder 1, main motor 2, hydraulic system motor 3, base 4, encoder 5, hydraulic system 6, left frame 7, and main oil cylinder 8. Lower inclined block 9, grating ruler 10, supporting roller 11, lower roller 12, upper roller 13, idler seat 14, upper inclined block 15, lower roller seat 16, right frame 17, upper roller movable support 18, turning Composition to oil cylinder 19, CPU, touch screen. Left frame 7 and right frame 17 are fixedly installed on bottom frame 4, upper roller 13 left ends are fixed on left frame 7, and encoder 5 is installed, upper roller 13 right ends and upper roller movable support 18 are assembled on the right Rack 17. The lower roller 12 is a driving roller, and a coupling is installed on the left end of the lower roller 12. The coupling is connected with the low-speed shaft of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com