A type selection method and device for a fuel injector

A technology of injector and optimization method, which is applied in the directions of fuel injection device, charging system, machine/engine, etc., can solve the problems of long time consumption, large influence of selection results, and complicated selection process of injector, so as to save time. , Fast and accurate selection, accurate and objective results of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to enable those skilled in the art to better understand the solution of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and implementation manners.

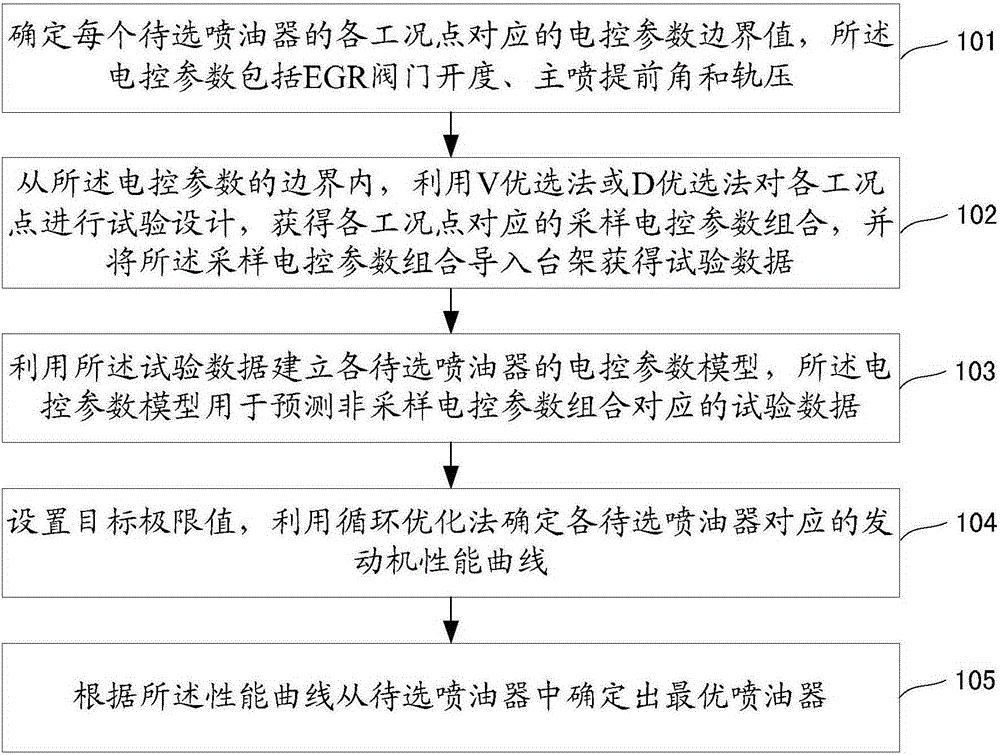

[0053] see figure 1 , shows the flow chart of Embodiment 1 of the fuel injector type selection method of the present invention, which may include:

[0054] Step 101, determine the boundary value of the electronic control parameter corresponding to each operating point of each candidate injector, and the electronic control parameter includes the opening degree of the EGR valve, the advance angle of the main injection and the rail pressure.

[0055] The scheme of the present invention is to select the type of fuel injector through modeling and simulation. The electric control parameters involved in the model mainly include EGR valve opening, main injection advance angle, and rail pressure. Electronic control para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com