Bevel gear combination

A technology combining gears and helical gears, applied to belts/chains/gears, elements with teeth, portable lifting devices, etc., to achieve the effects of less difficulty in production, convenient assembly, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

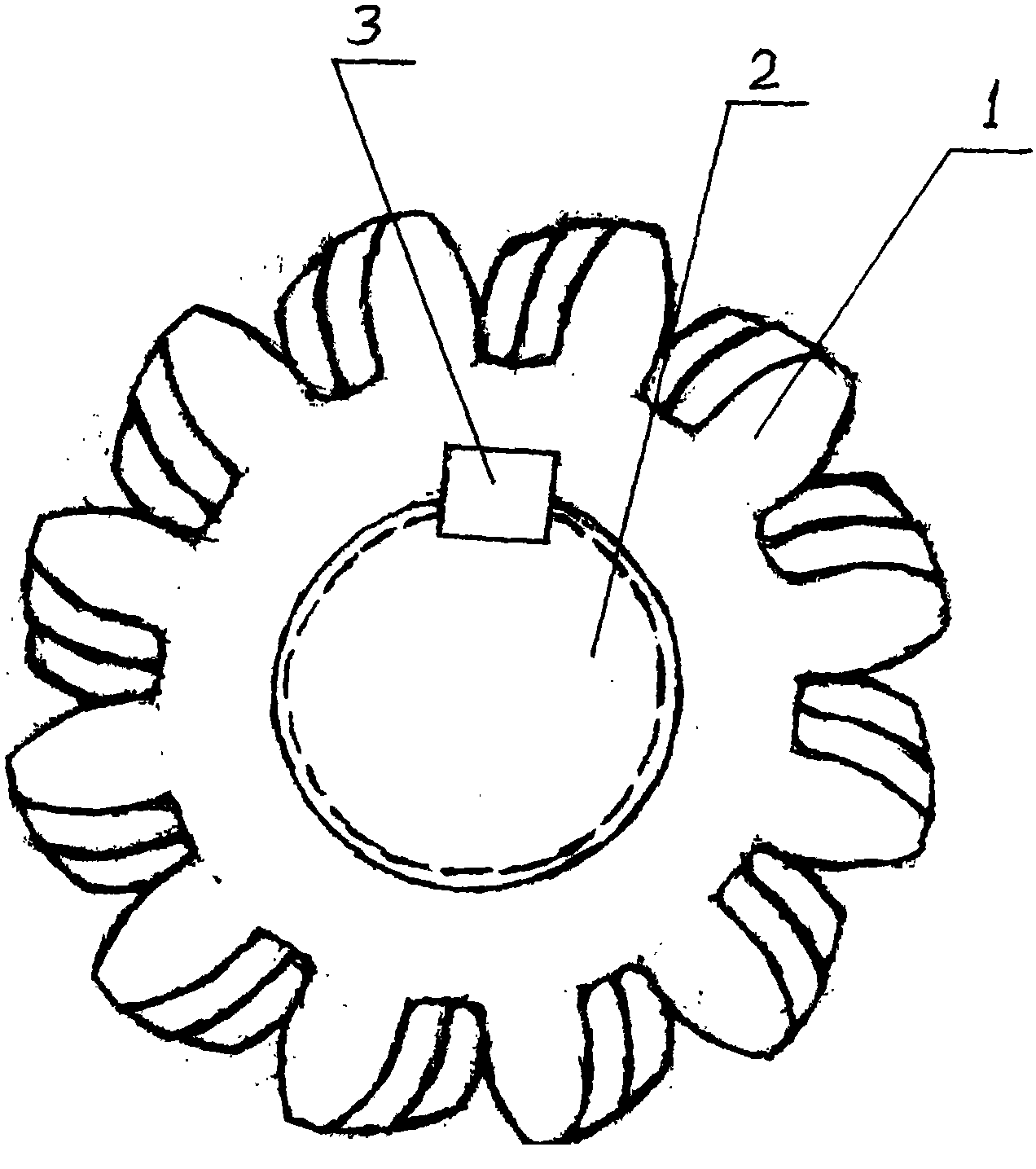

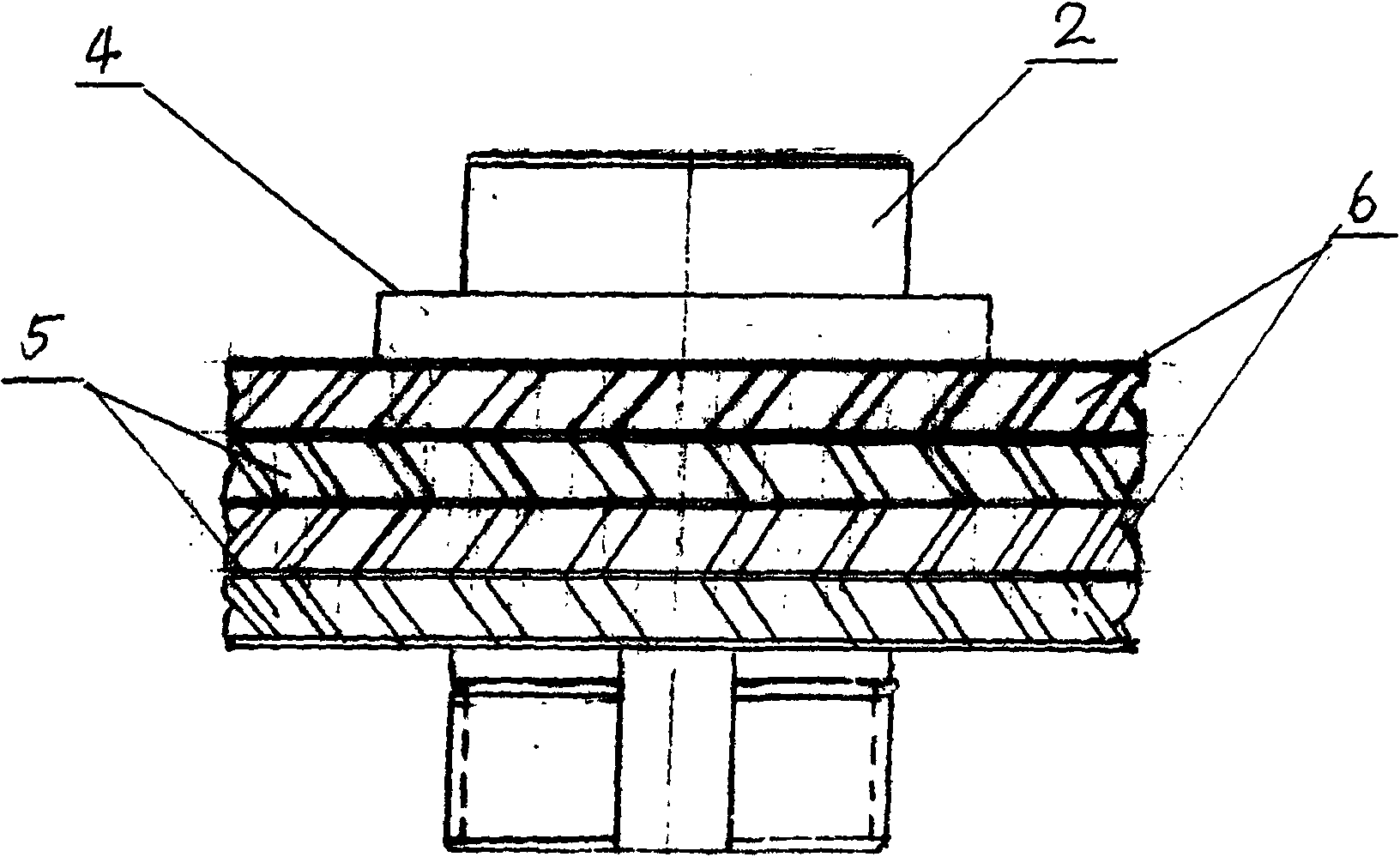

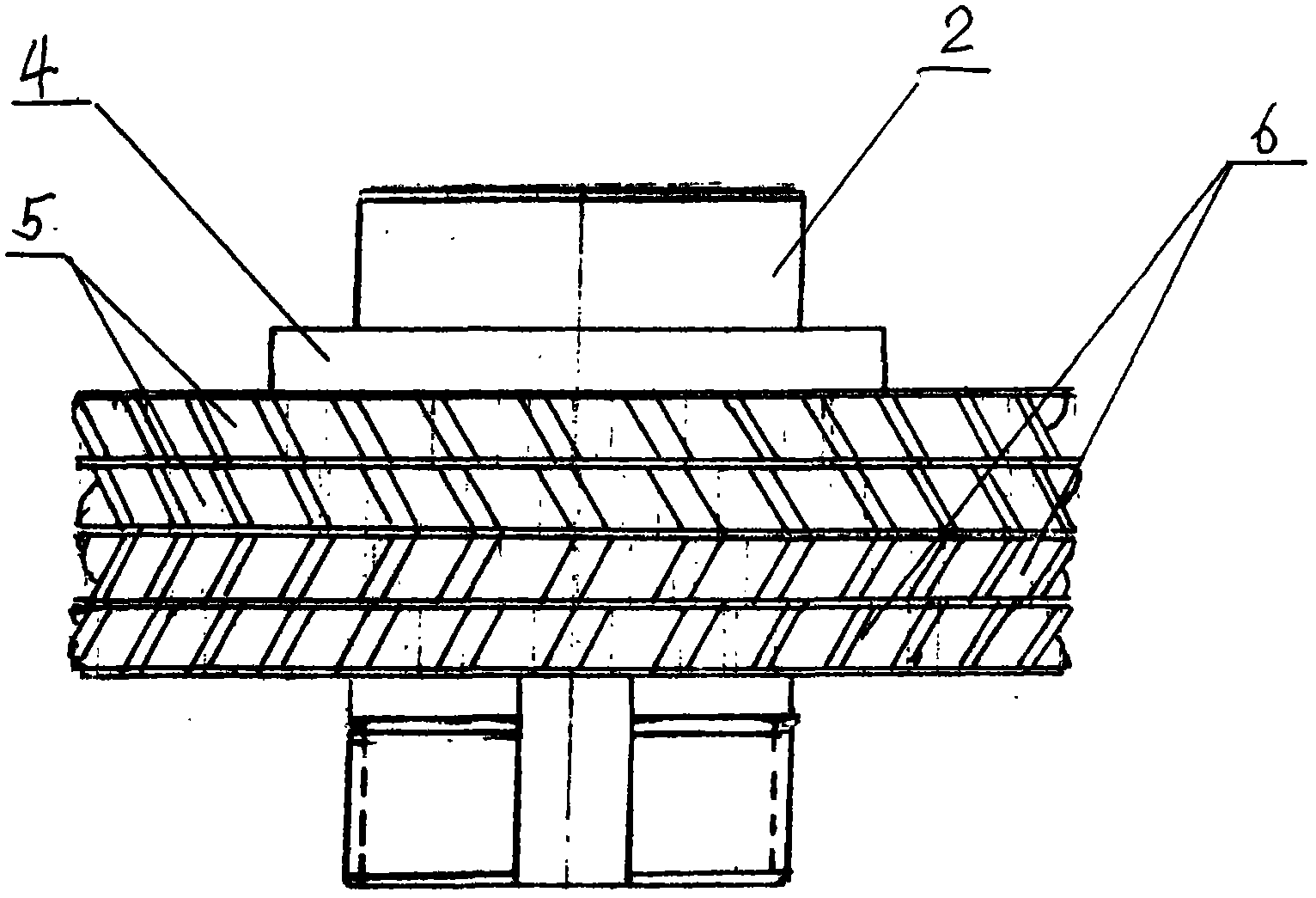

[0011] In the figure, the helical gear combined gear (1) is installed on the gear central shaft (2), the keyway is machined on the gear central shaft (2), and the center holes of each gear in the helical gear combined gear (1) are machined respectively. The positioning keyway, the helical gear combination gear (1) is connected together with the gear central shaft (2) through the inner positioning key (3), and the shaft shoulder (4) acts as a limit to the helical gear combination gear (1). Gear Combination Gear (1) has two combinations, the first is left-handed helical gear (5) and right-handed helical gear (6) are divided into two groups, and then these two groups of helical gears are arranged opposite to each other and assembled on the gear central axis (2 ), the second is that the left-handed helical gear (5) and the right-handed helical gear (6) are combined into a pair in units of two, and then arranged and assembled on the gear central shaft (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com