Pressure gage

A technology of pressure gauge and liquid pressure, which is applied in the direction of fluid pressure measurement by changing the ohmic resistance, which can solve the problems of complex structure of pressure gauge, high cost, unfavorable maintenance, etc., to reduce test equipment and manpower and material resources, reduce impact, and debug and easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained by way of examples below, but the present invention is not limited to the scope of the described examples.

[0028] The pressure gauge of this embodiment uses a low-power MCU, battery power supply, and periodic measurement methods, so that the power supply is built in the pressure gauge. On the one hand, the structure of the pressure gauge is reduced and the interference resistance is improved.

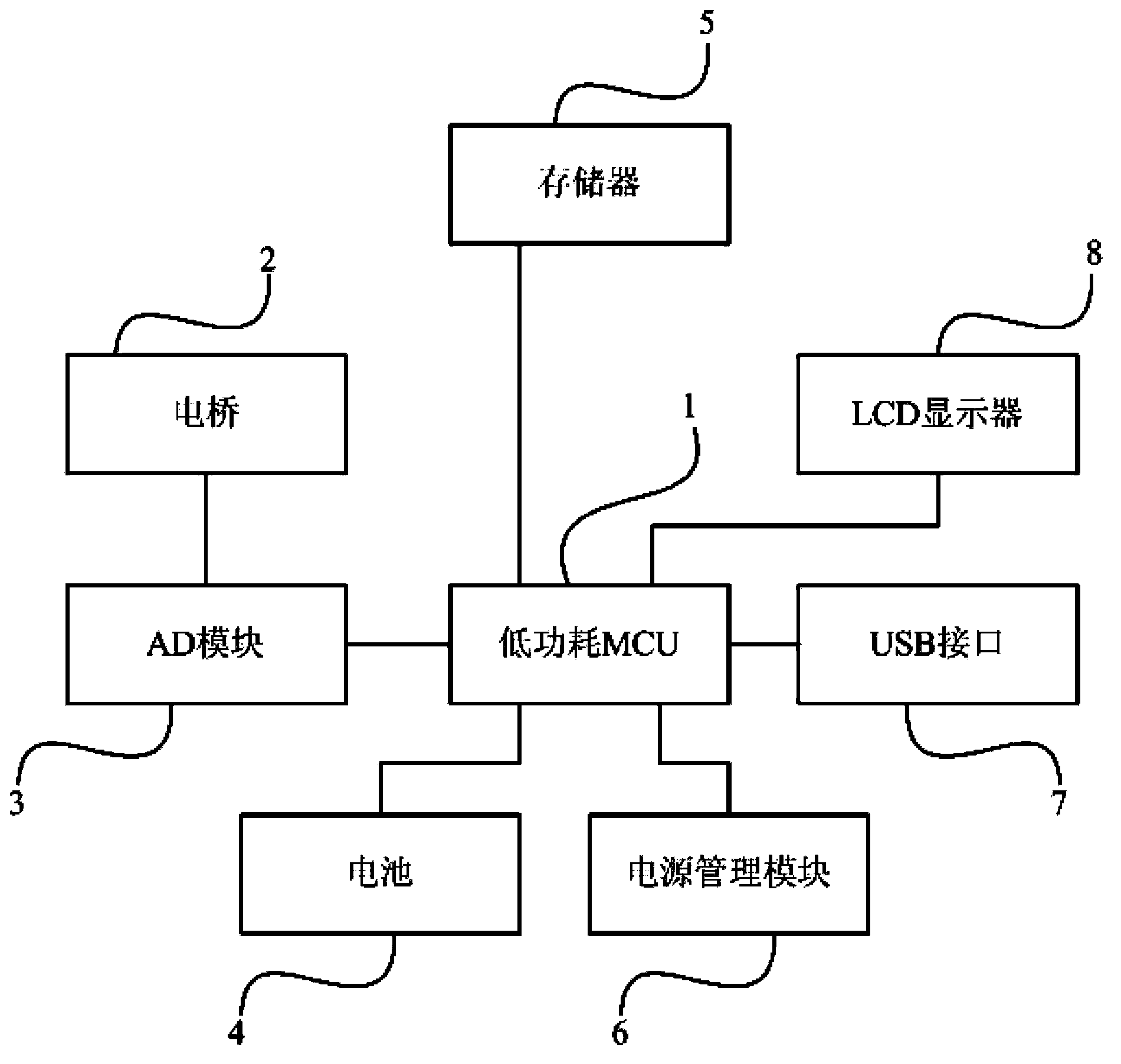

[0029] Specifically, such as figure 1 As shown, the pressure gauge of this embodiment includes a low-power MCU1, a bridge 2, an AD module 3, a battery 4, a memory 5, a power management module 6, a USB interface 7 and an LCD display 8.

[0030] The electric bridge 2 is composed of 4 strain gauges and attached to an elastic body (not shown in the figure), and the output of the electric bridge 2 composed of the strain gauges is connected to the AD module 3. The AD module 3 is connected to the low power consumption MCU1 through an SPI (High...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com