Method for forming photo composition

A patterning and line patterning technique used in the field of forming nanoscale structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

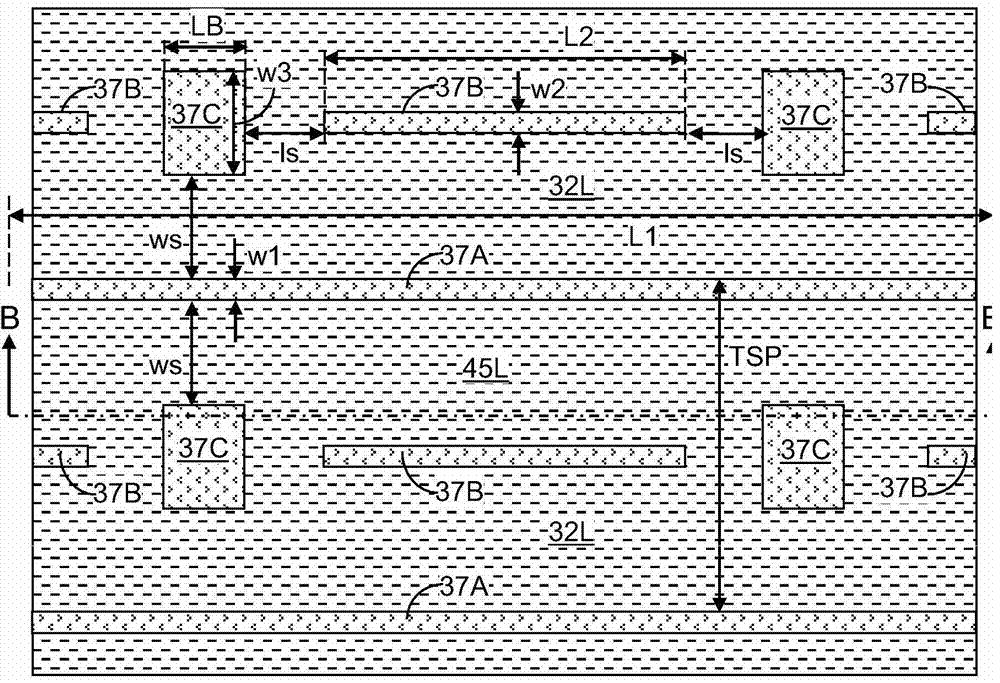

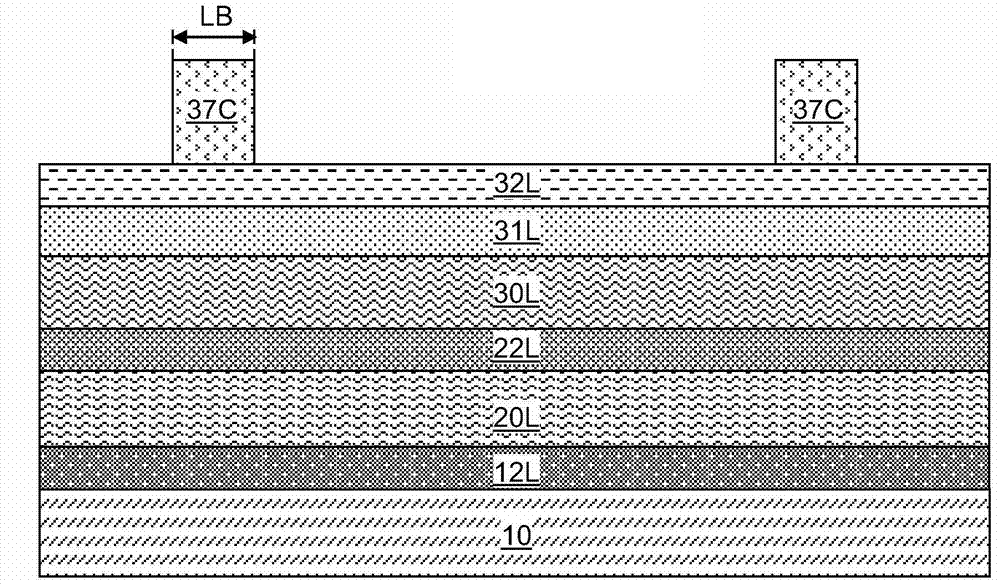

[0049] As described above, the present disclosure relates to a method of forming a nanoscale structure, and more particularly, to a method of forming a nanoscale fin structure cut perpendicular to a length direction, and a structure for forming the nanoscale fin structure. Aspects of the present disclosure will now be described in detail using the accompanying drawings. It should be noted that identical and corresponding elements are denoted by the same reference numerals.

[0050] refer to Figure 1A and 1B , the first exemplary patterning structure according to an embodiment of the present disclosure includes a material stack formed over the substrate 10 . The material stack may include, from bottom to top, a first material layer 12L, an underlying organic planarization layer (OPL) 20L, a second material layer 22L, an organic planarization layer (OPL) 30L, a hard mask layer 31L and Neutral polymer layer 32L. Subsequently, a patterned template layer ( 37A, 37B, 37C) is for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com