Anti-loosening type elastic rapid connecting device for welding cables

A welding cable and quick connection technology, which is applied to the two-part connection device, the parts of the connection device, the connection, etc., can solve the problems of fire hazard, false connection or looseness, and burnout of the welding machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

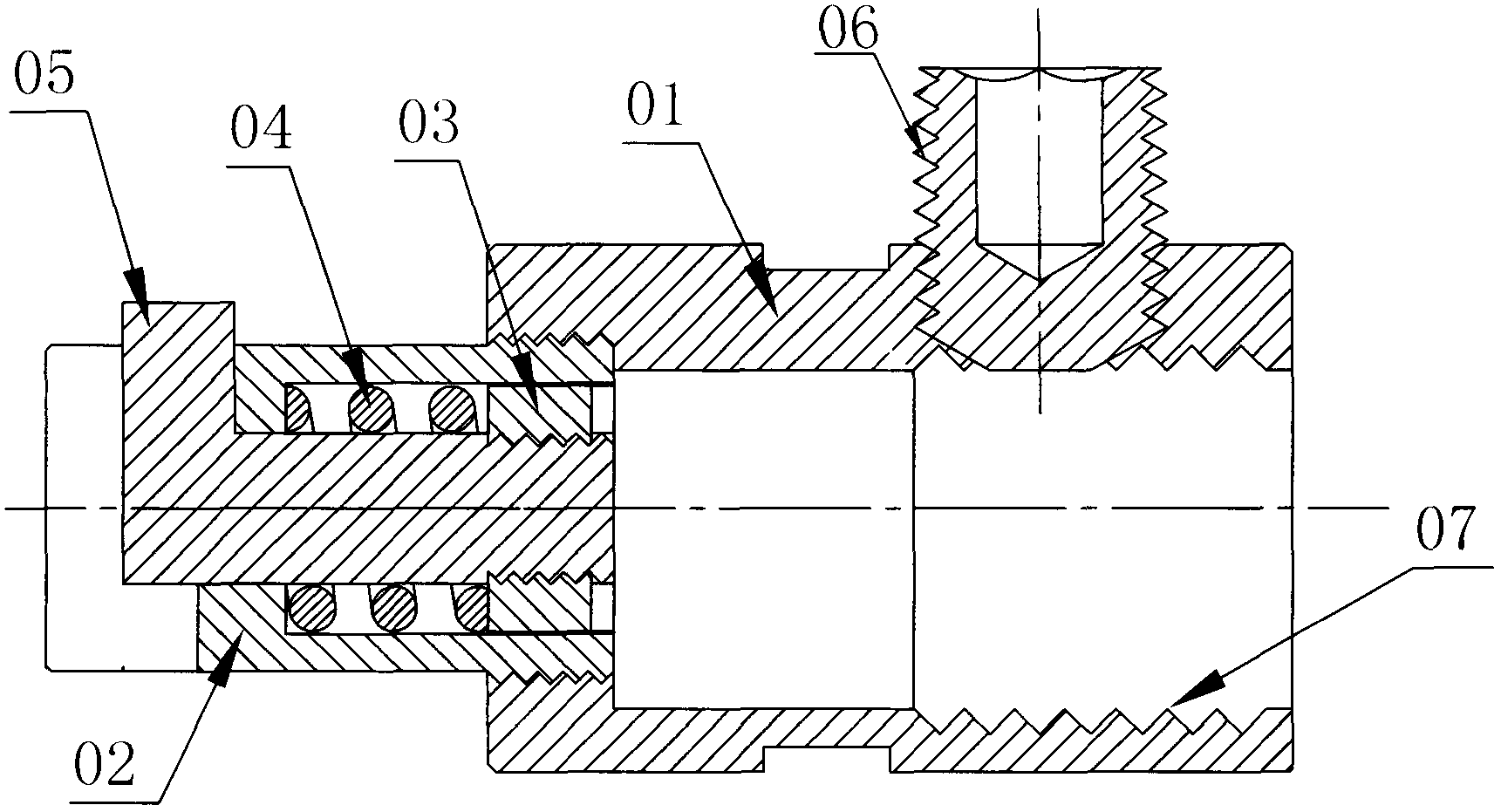

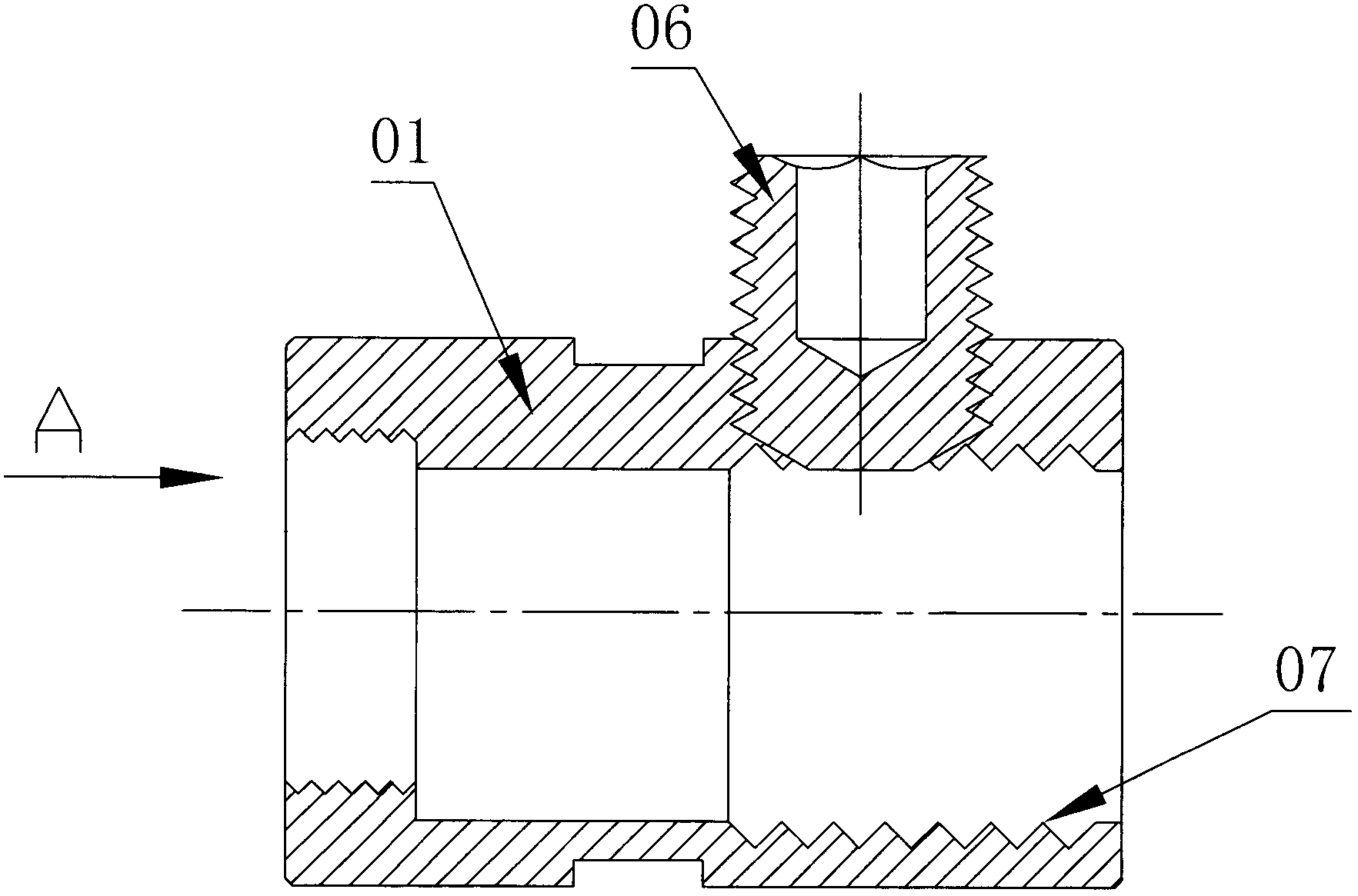

[0018] The anti-loose elastic welding cable quick connection device of the present invention is divided into two parts: respectively, the male plug ( figure 1 ) and female socket ( figure 2 ), the male plug is divided into: cable connection body 01, connecting rod 02, movable chuck 05, spring 04, spring compression nut 03, and cable compression screw 06.

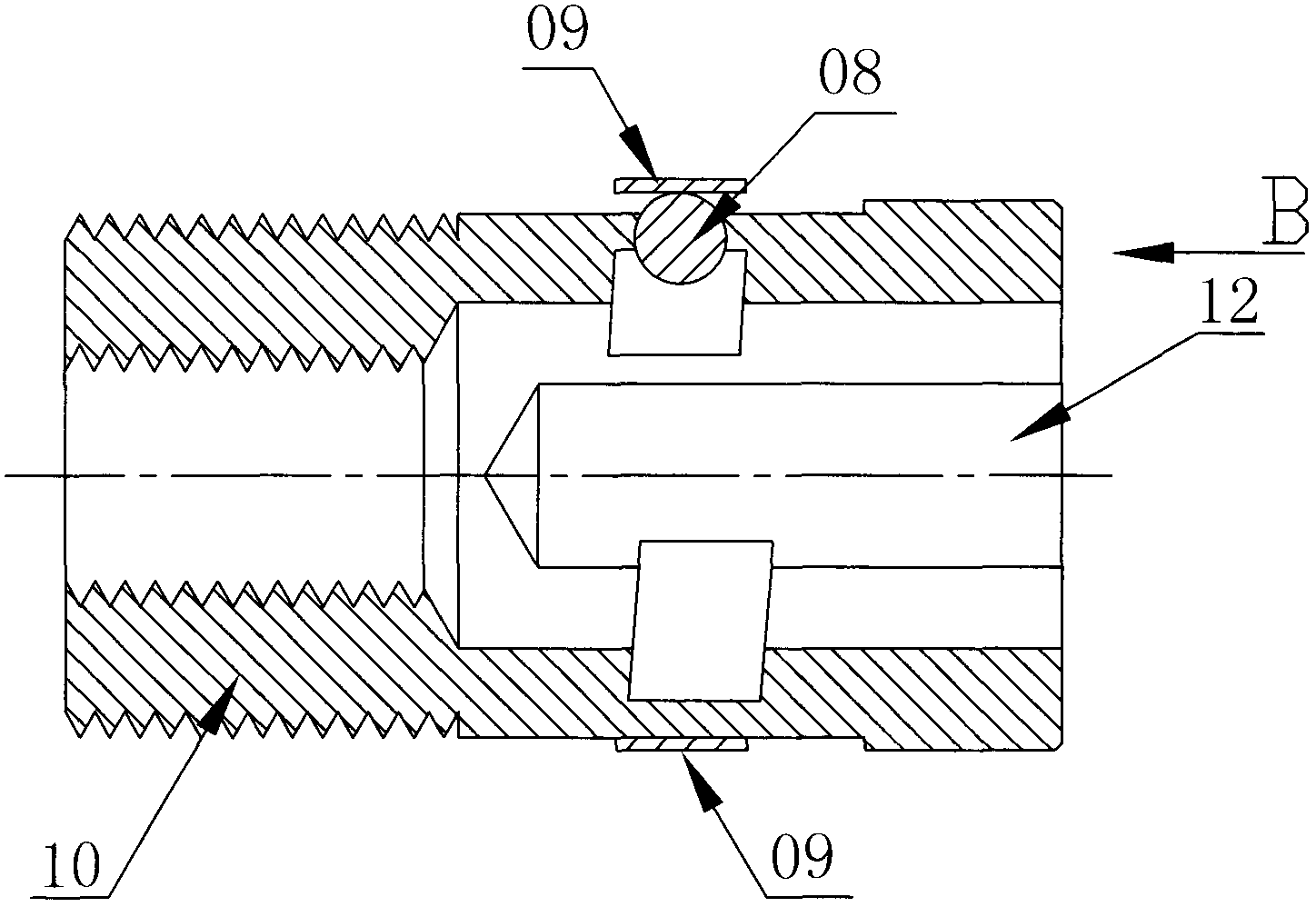

[0019] female socket figure 2 Divided into: cable connection main body 11, limit steel ball 08, elastic steel sheet 09.

[0020] Will Figure 7 Activity card head from Figure 4 Insert the connecting rod on the left, from the Figure 4 Install the spring 04 on the right side, then install the spring compression nut 03, and tighten the spring compression nut 03 to the appropriate strength, and screw the connecting rod with the movable chuck into the image 3 Tighten.

[0021] On the female socket slot, drill a counterbore at the ultimate position of the buckle stroke, install the upper limit steel ball 08 on the count...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com