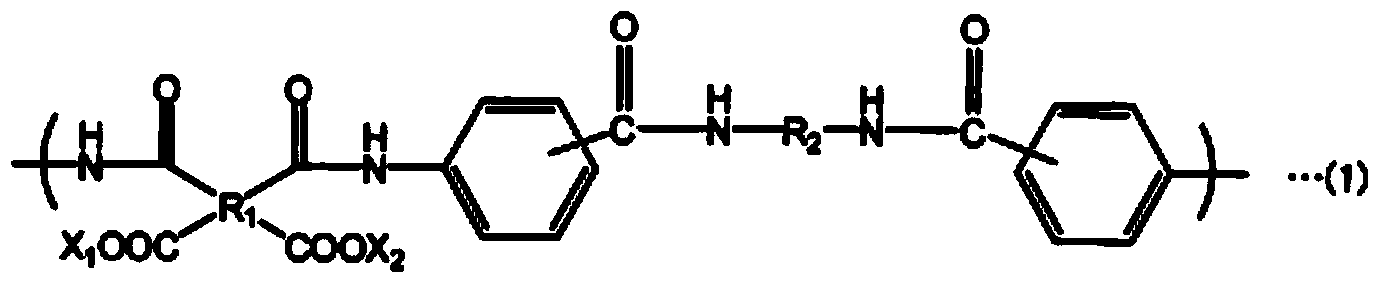

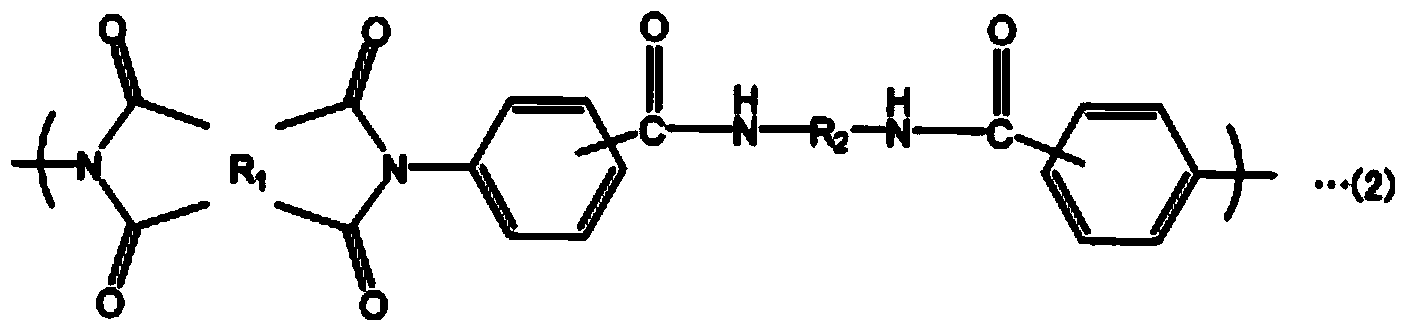

Polyamic acid resin composition, polyimide resin composition, polyimide oxazole resin composition, and flexible substrate containing same

A technology of polyamic acid resin and polyimide resin, applied in the field of flexible substrates, can solve the problems of high transparency and low birefringence, and achieve low birefringence, high light transmittance, and excellent heat resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0182] PMDA-HH 2.7704 g (12 mmol), HFHA 7.4706 g (12 mmol), and NMP 50 g were added to a 100 mL 4-necked flask under a dry nitrogen stream, and heated and stirred at 80°C. After 8 hours, cool to form a varnish.

Embodiment 2

[0184] PMDA-HS2.7704g (12mmol), HFHA7.4706g (12mmol), and NMP50g were added to a 100mL 4-necked flask under dry nitrogen flow, and it heated and stirred at 80 degreeC. After 8 hours, cool to form a varnish.

Embodiment 3

[0186] 3.4441 g (11 mmol) of BPDA-H, 6.7969 g (11 mmol) of HFHA, and 50 g of NMP were added to a 100 mL four-neck flask under a dry nitrogen flow, and heated and stirred at 80°C. After 8 hours, cool to form a varnish.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap