Pipe-bending machine

A technology of pipe bending machine and pipe bending shaft, which is applied in the field of long overall length or softer heat dissipation pipes, where there are many production elbows, and can solve the problems that the bending cannot be completed smoothly, so as to reduce the working intensity and control the process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

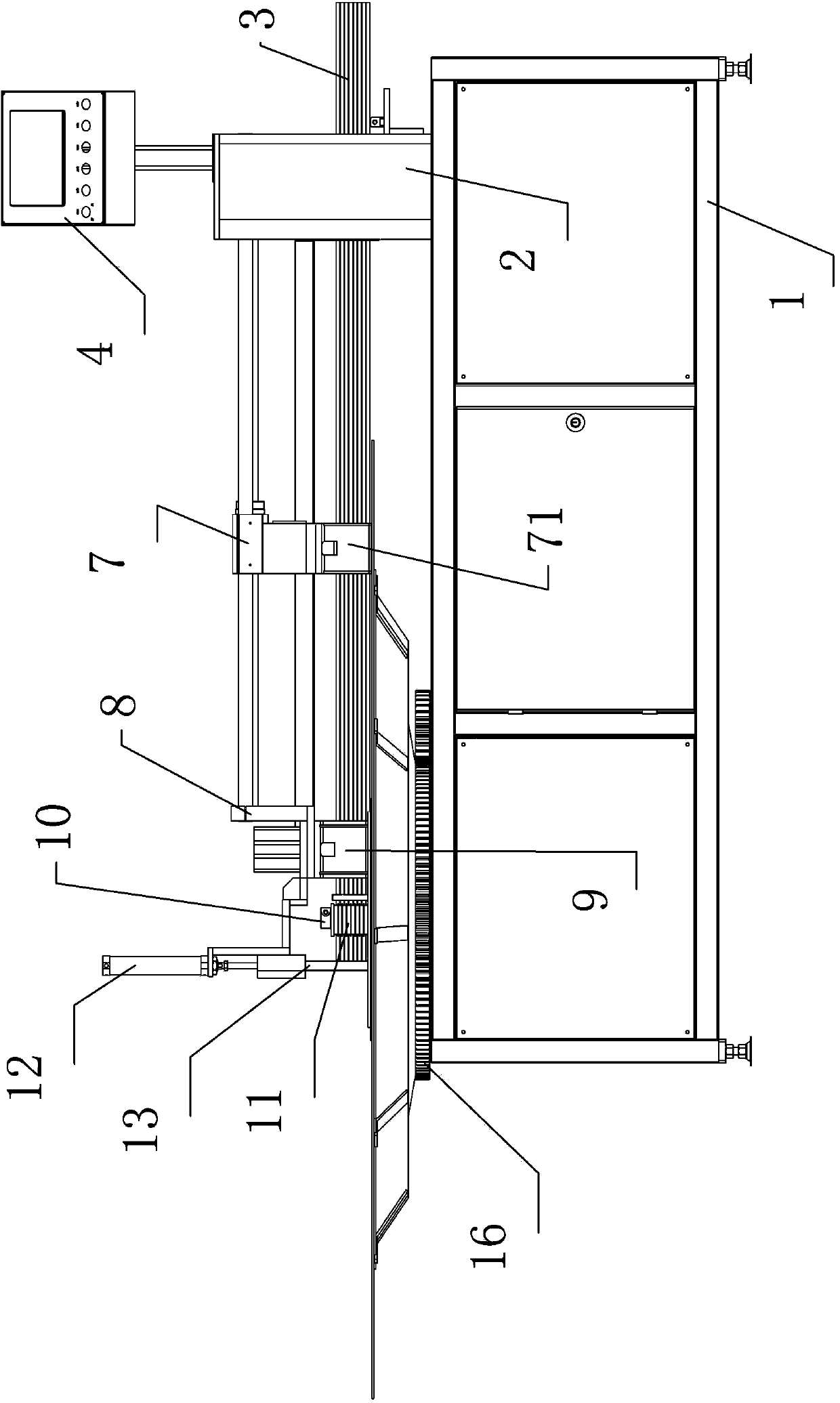

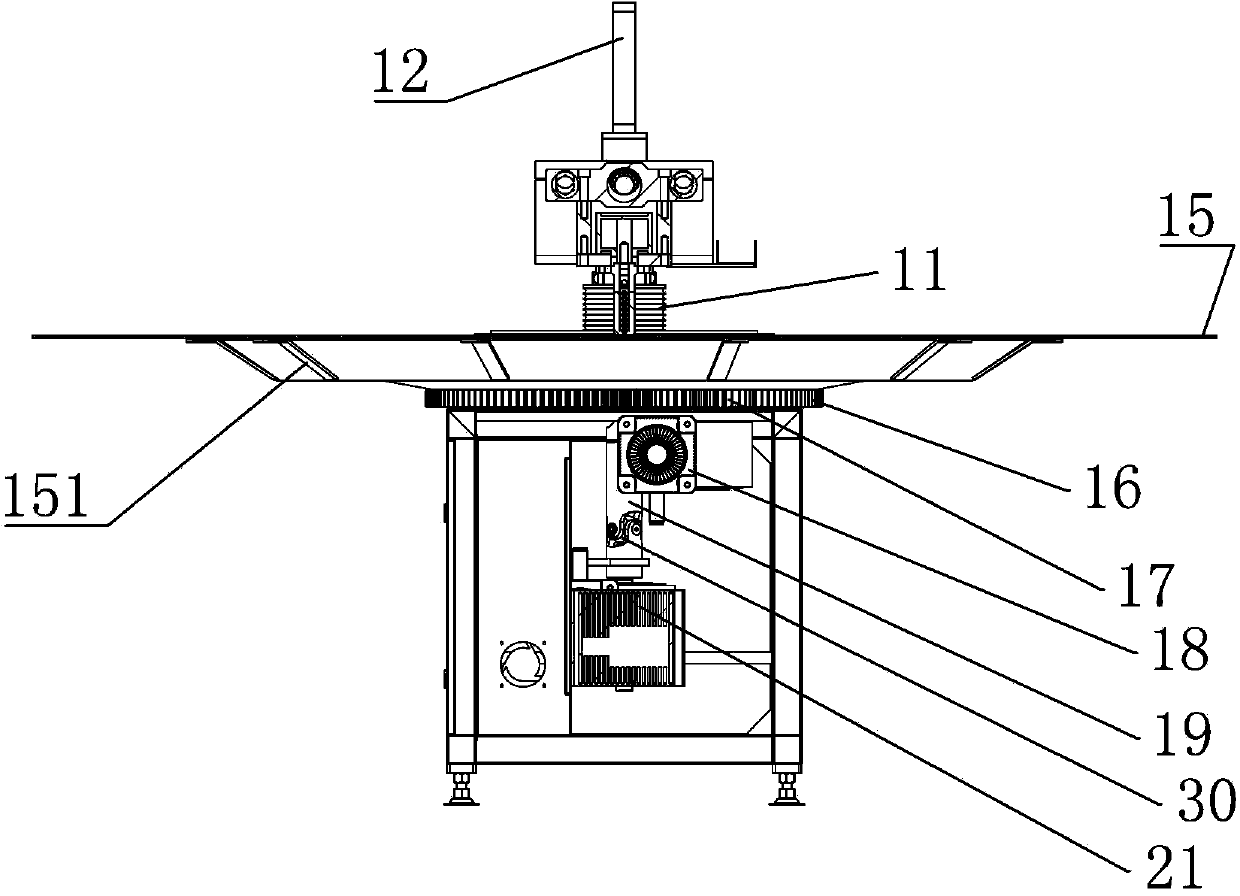

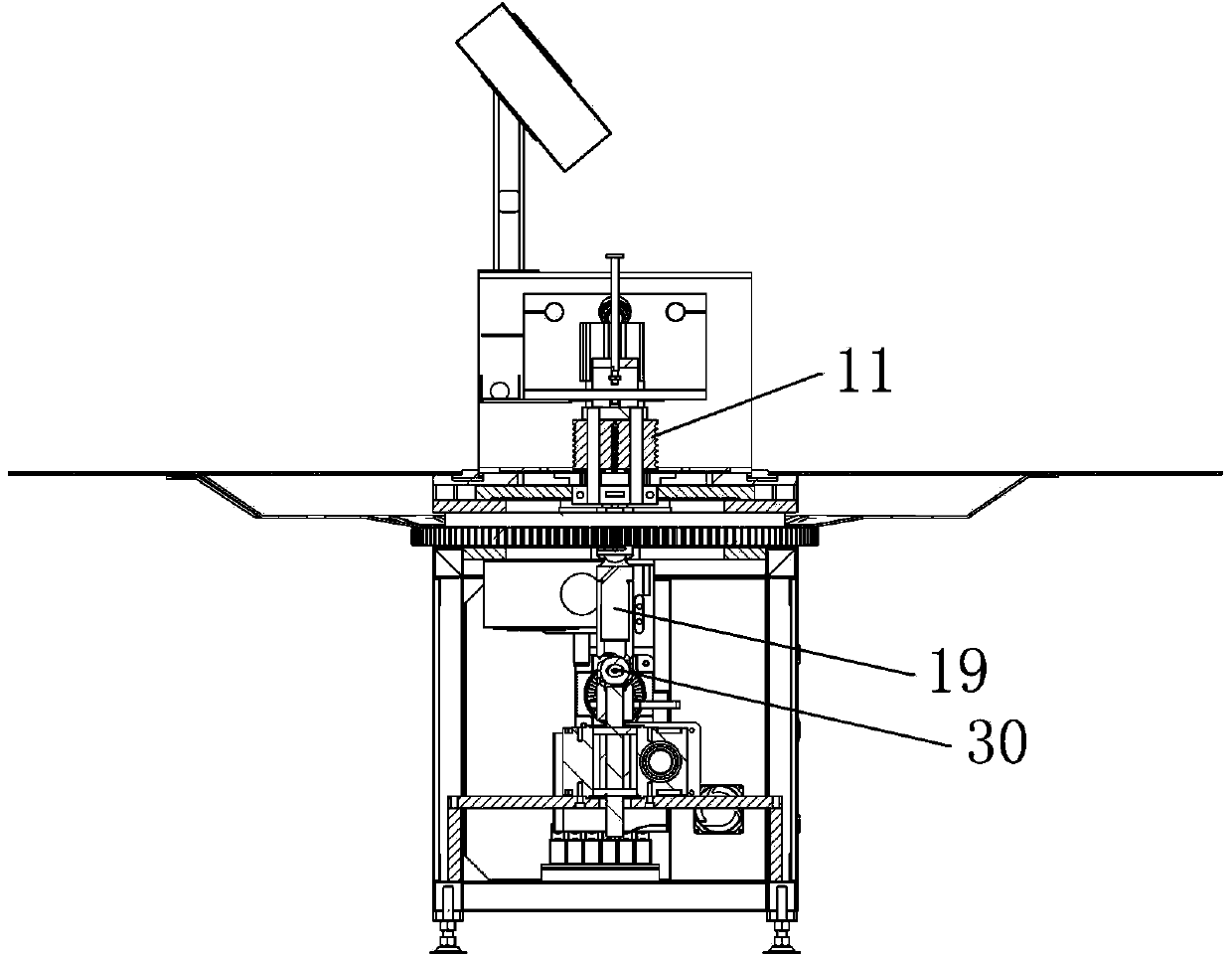

[0032] Such as figure 1 As shown in -6, the pipe bending machine of the present invention includes: a cabinet 1, a frame 2, pipe fittings 3, a console 4, a guide rail 5, a screw 6, a feeding clamp 7, a support 8, a clamping mechanism 9, and a pipe bending shaft 10, pipe bending wheel 11, cylinder 12, bar 13, supporting plate 14, turntable 15, large gear 16, pinion 17, servo motor 1 18, transmission shaft 19, first universal joint 20, gearbox 21, Servo motor two 22, limit seat 23, eccentric positioning mechanism 24, disk one 25, annular boss one 26, fixed plate 27, hollow support 28, the second universal joint 30.

[0033] The upper part of the chassis 1 is provided with a frame 2, the upper part of the frame 2 is provided with a console 4, the left side of the frame 2 is fixed, and a guide rail 5 and a lead screw 6 are arranged in parallel, and a through hole for passing through the pipe fitting 3 is provided in the frame 2. The left end of the guide rail 5 and the lead screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com