Stripping conveying belt

A conveyor belt and comb stripping technology, applied in conveyors, threshing equipment, belt fasteners, etc., can solve problems such as inability to adapt to long-term operation, shortening of conveyor belt service life, fatigue and heating of lap joints, etc. The effect of removing efficiency, reducing breakage and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

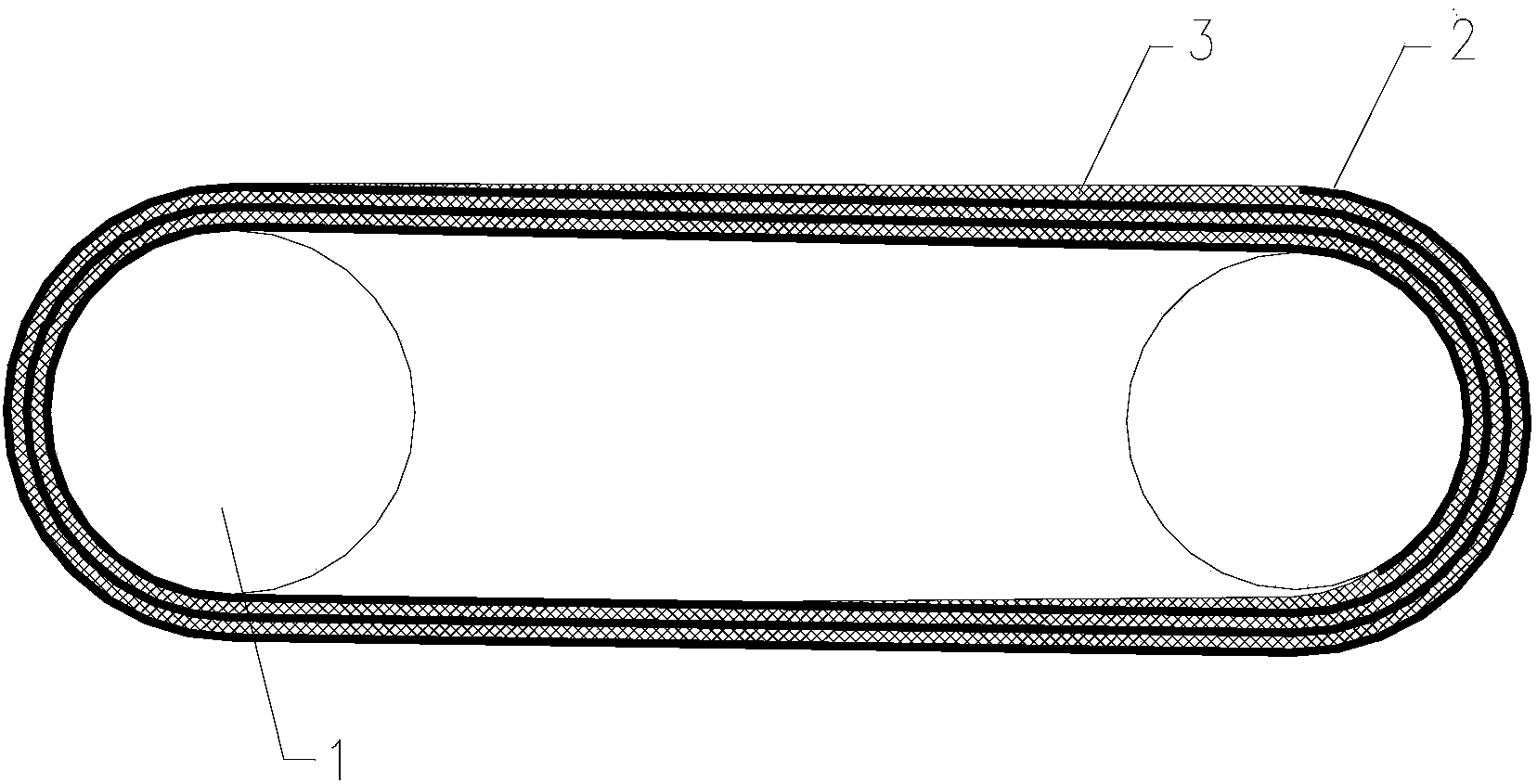

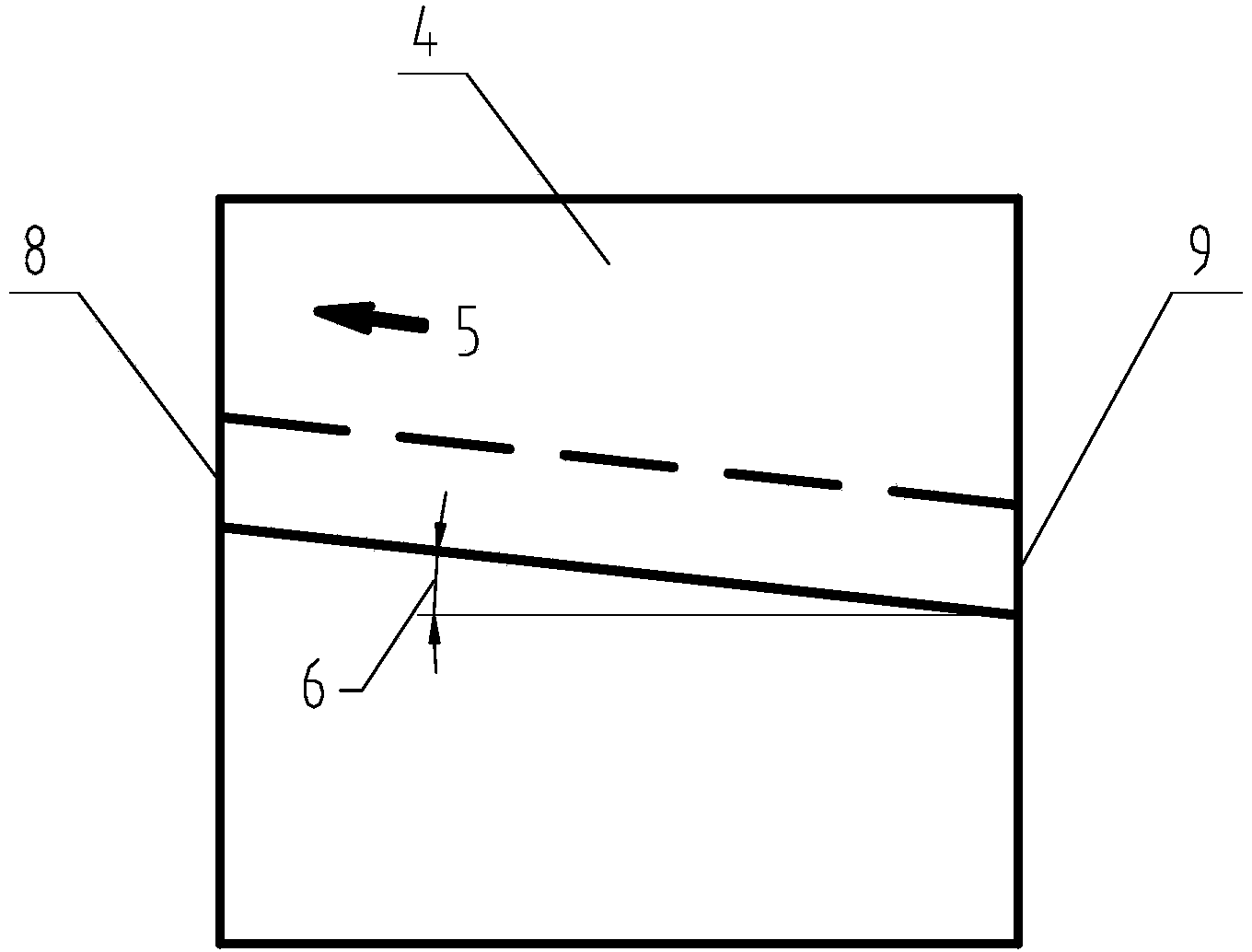

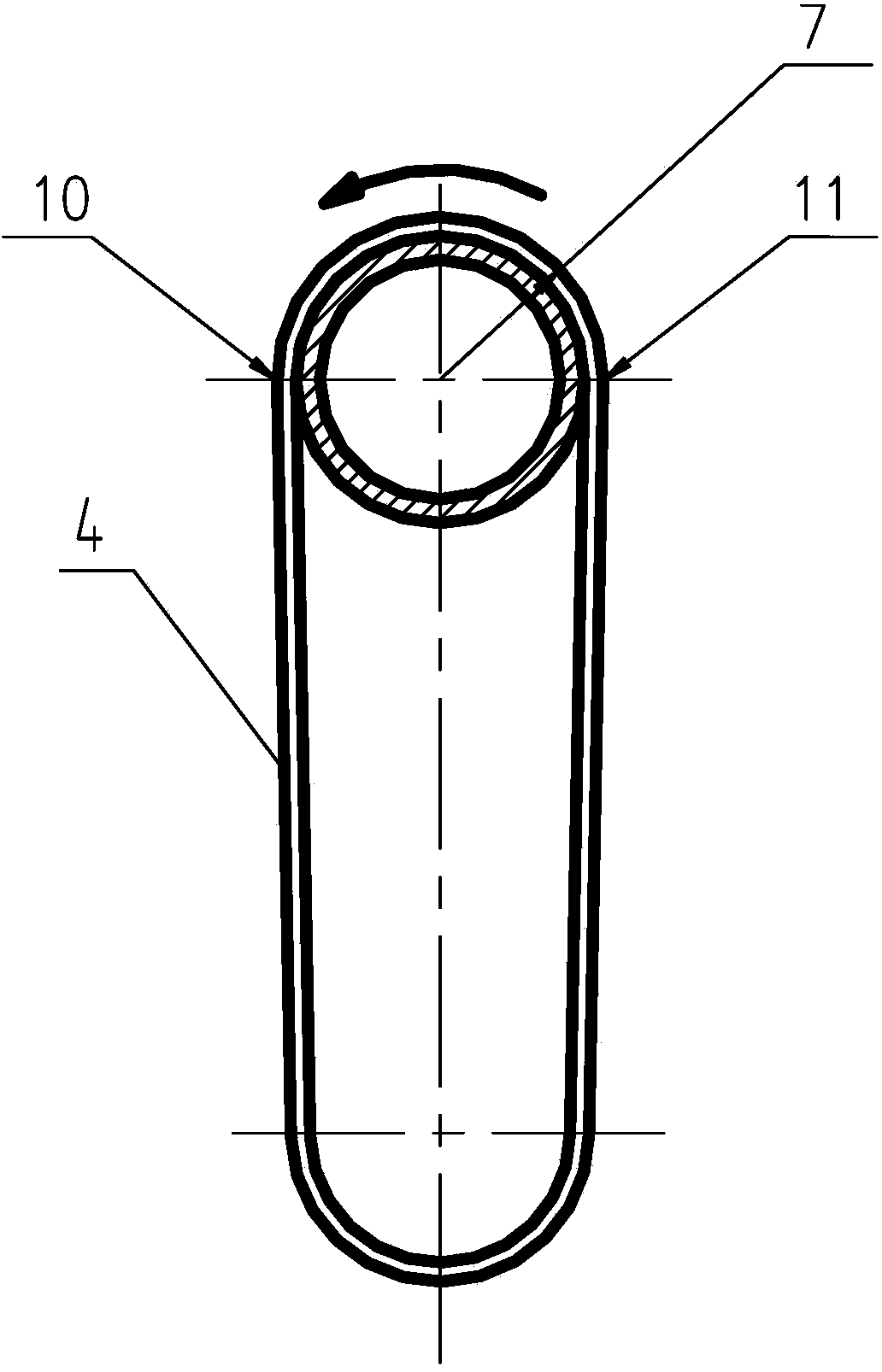

[0013] The preferred embodiment of the present invention is like this: with reference to Figure 1 ~ Figure 3 , the polyester fabric skeleton is wound more than one circle without interruption between two custom-made rollers 1 to make a multi-layer annular polyester fabric skeleton 2. During the winding process, natural rubber is evenly laid on the surface of the skeleton 3. Accelerators, vulcanizing agents, softeners, and fillers are added to the natural rubber 3 in a certain proportion, and finally the multi-layer annular polyester fabric skeleton 1 and the natural rubber 2 are integrally bonded by a vulcanization process to form a conveyor belt . The multi-layer annular polyester fabric skeleton 2 is used to increase the flexibility and strength of the conveyor belt, so that the conveyor belt can withstand greater pulling force, which can increase the life of the conveyor belt several times. On the surface of the polyester (polyester) fabric skeleton 2 The natural rubber 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com