Flocculation reaction pool of maze turbulent folded plate

A folded plate flocculation and reaction tank technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of high-strength secondary collision that cannot form a dense reaction zone, and the efficiency of flocculation reaction needs to be improved, so as to save investment costs and improve The effect of the reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

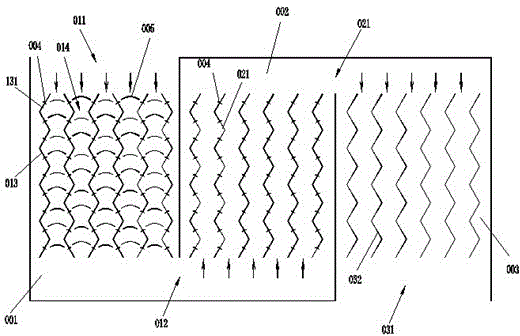

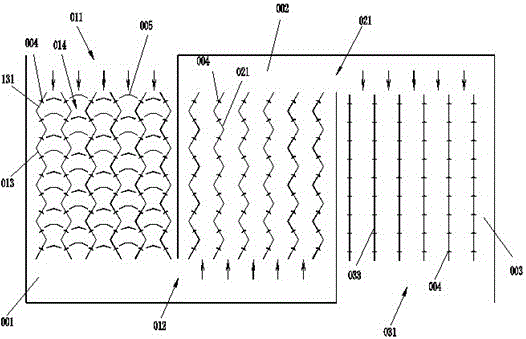

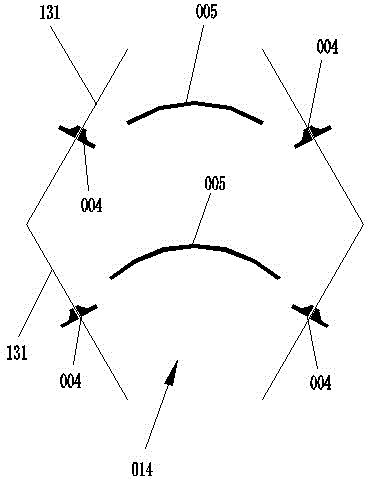

[0012] Example 1: A labyrinth turbulent baffle flocculation reaction tank, including A reaction tank 001, B reaction tank 002 and C reaction tank 003 connected in series, the upper end of A reaction tank 001 is the water inlet 011, the bottom end 012 is connected to the B The reaction pool 002 is connected, the overflow port 021 at the upper end of the reaction pool B is connected with the reaction pool C 003, and the bottom end 031 of the reaction pool C is connected to the water. The A reaction pool 001 is provided with several baffles 013 symmetrically arranged at intervals. The baffle 013 is a wavy plate body composed of a number of slanted plates 131 zigzag spliced, and the flocculation channel 014 is formed between adjacent baffles 013, and the middle section of each slanted plate 131 of the baffle 013 is provided with fins 004, the center of each flocculation channel 014 is provided with several arc-shaped turbulence plates 005. Corresponding. The fins 004 are arc-shap...

Embodiment 2

[0013] Example 2: A labyrinth turbulent flow baffle flocculation reaction tank, including A reaction tank 001, B reaction tank 002 and C reaction tank 003 connected in series, the upper end of A reaction tank 001 is the water inlet 011, and the bottom end is 012 It is connected to the B reaction pool 002, the overflow port 021 at the upper end of the B reaction pool is connected to the C reaction pool 003, and the water is discharged from the bottom end 031 of the C reaction pool. The A reaction pool 001 is provided with several baffles 013 symmetrically arranged at intervals , the baffle 013 is a wave-shaped plate formed by a number of slanted plates 131 zigzag spliced, and the flocculation channel 014 is formed between adjacent baffles 013, and the middle section of each slanted plate 131 of the baffle 013 is provided with Fins 004, each flocculation channel 014 center is provided with a number of arc-shaped turbulence plates 005, the arc-shaped openings of each arc-shaped tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com