Technology for manufacturing strong non-woven cloth

A manufacturing process and technology of non-woven fabrics, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of separation of skin non-woven fabrics and glass fiber mesh cloth, loss of usability, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

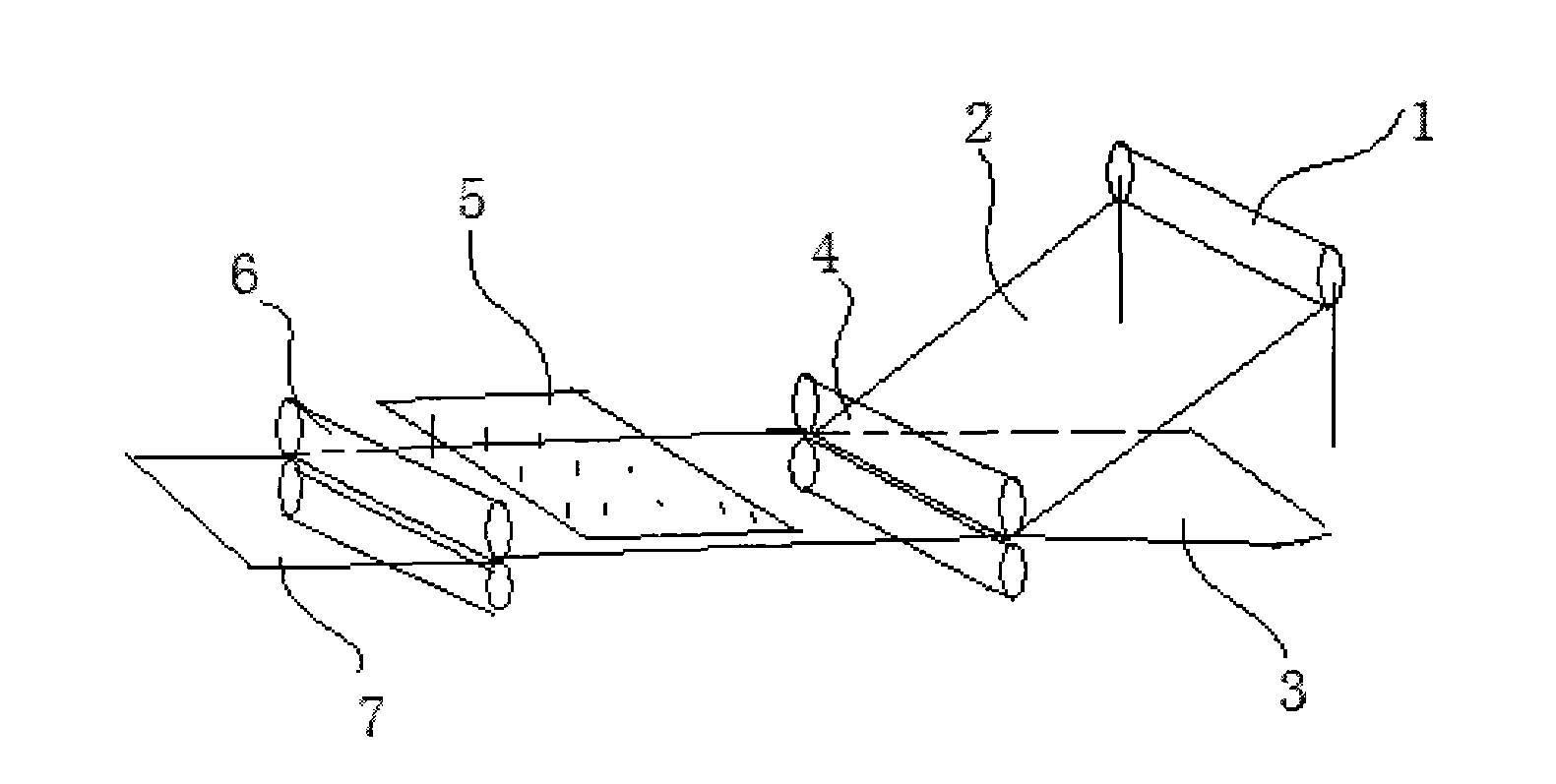

[0015] Below in conjunction with accompanying drawing, the invention is further described:

[0016] Firstly, the raw materials of polyester staple fiber are opened and loosened into filaments that are easy to card, and then combed. Many filaments are carded into cotton webs. Sometimes in order to increase the strength, it is necessary to combine two or three different polyester staple fibers. It is opened, then blended and carded into a web. After the cotton net is obtained, the net is laid, that is, the cotton net is repeatedly overlapped, and the number of overlapping layers is increased, generally four layers, or more layers, depending on the thickness and strength of the required product, the greater the required thickness and strength , the more overlapping layers are required.

[0017] The overlapping cotton nets are needled by the needling machine. Generally, four rows of needling machines are used for needling in sequence. The needles are fixed on the needle plate. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com