Method of stabilizing soft foundation through deep processing of bagged sand bed in freezing environment

A soft soil foundation and sand cushion technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of high economic cost, long construction time, long construction period, etc., and achieve good economic benefits and social benefits Benefits, construction cost reduction, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

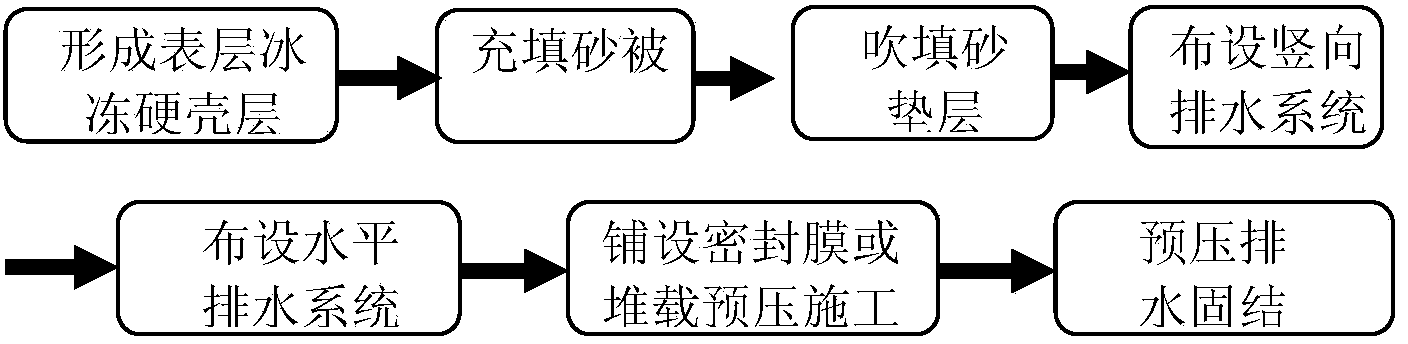

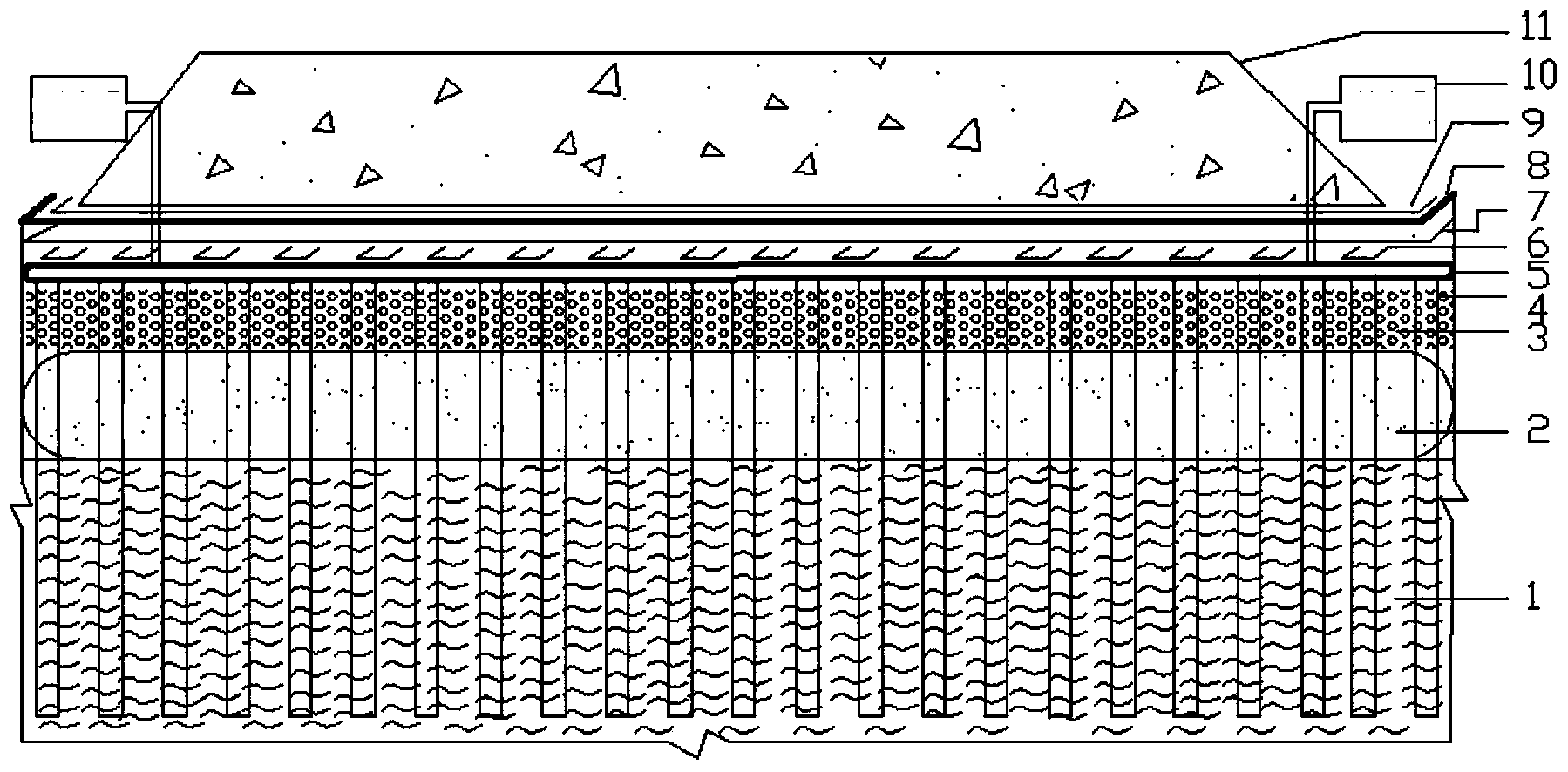

[0029] like figure 1 As shown, it is the construction process of the present invention, which includes the following steps in turn: forming the surface frozen hard crust, filling sand quilt, blowing and filling sand cushion, laying out vertical drainage system, laying out horizontal drainage system, laying sealing film or stacking Preloading construction, preloading drainage consolidation.

[0030] Taking the dredging reclamation foundation reinforcement of a certain national-level new area in my country as an example below, the specific implementation of the present invention is described as follows. The area is located at about 39° latitude, and the freezing period is from December to March of the following year. For specific construction operations, it is also necessary to consult meteorological data for many years, and scientifically arrange the process time nodes.

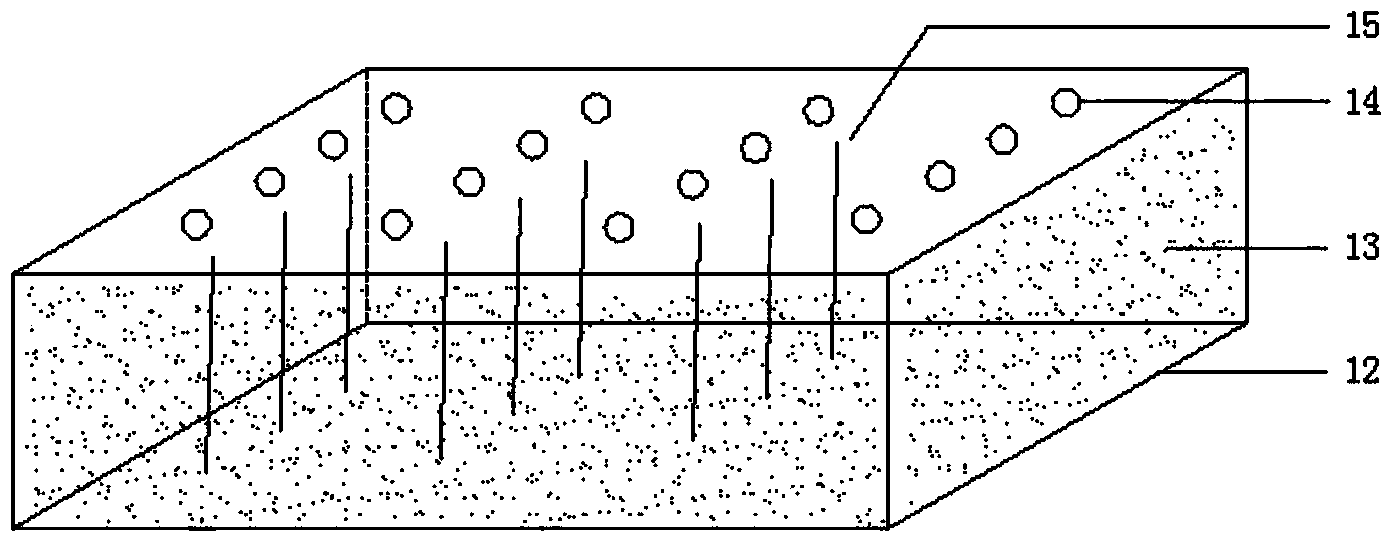

[0031] (1) After entering the freezing period, the soft soil 1 is frozen under natural freezing condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com