Detecting and reloading technology for load box

A technology of load box and supplementary load, applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve problems such as hidden safety hazards, inability to support the upper piles of foundation piles, and later construction of houses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

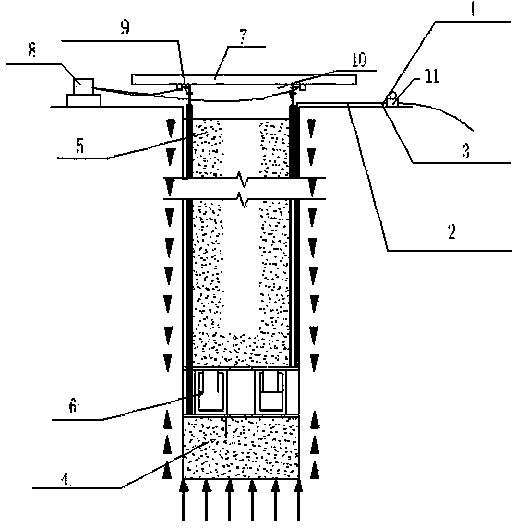

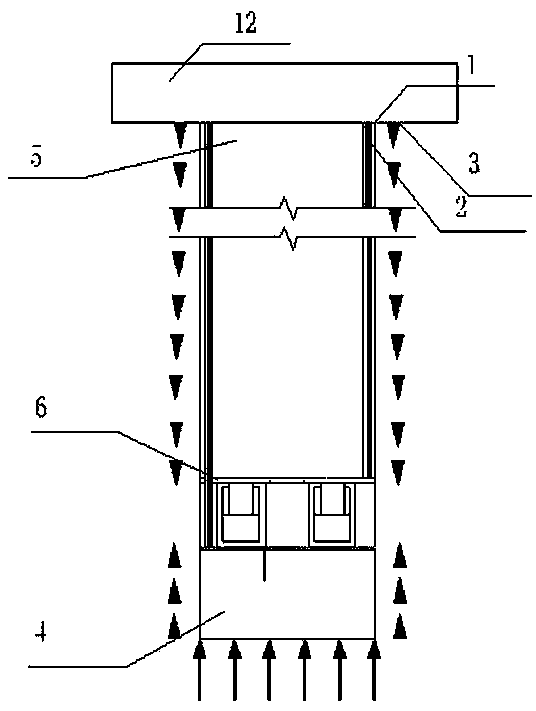

[0020] Attached below figure 1 , 2 The present invention is described in detail:

[0021] A load box detection supplementary loading process, the process includes the following process steps:

[0022] A), loading stage:

[0023] According to the tonnage of the load box 6, the load is carried out step by step, and the load of the next level can be added after the load of each level reaches a relatively stable level until the predetermined maximum load value is detected;

[0024] B), Unloading stage:

[0025] When the load reaches the maximum value, keep the pressure for a period of time and start to release the pressure. After each level of unloading, measure and read the residual settlement every 15 minutes. After reading twice, read it again every 30 minutes to unload the next level of load until the pressure is zero;

[0026] C), Supplementary loading stage:

[0027] After unloading, determine the maximum pressure of supplementary loading, load it to the characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com