Intercooler condensate to sump or positive crankcase ventilation flow

A technology for crankcase ventilation and condensate, which is applied in the direction of crankcase ventilation, machine/engine, engine lubrication, etc. It can solve problems such as unstable combustion, not allowing condensate to fully vaporize, and misfires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

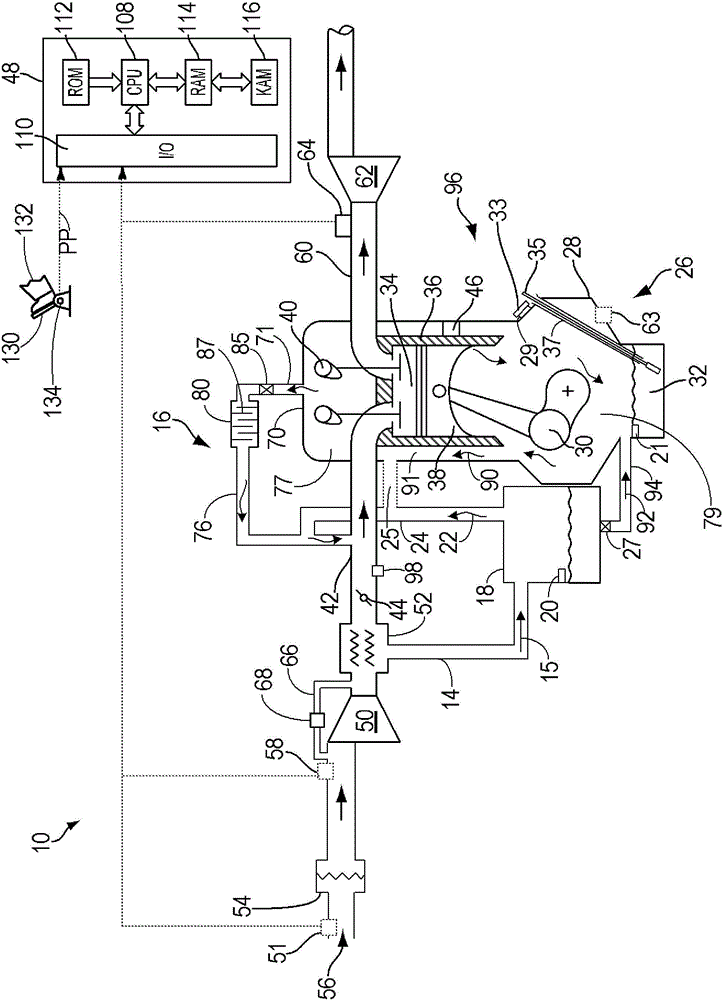

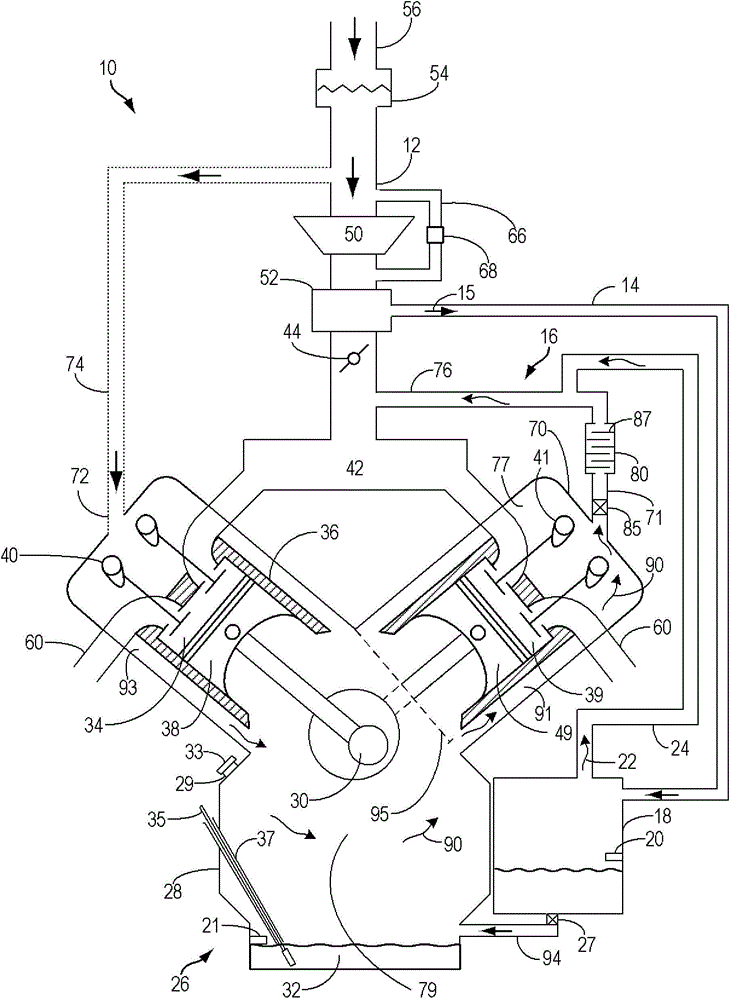

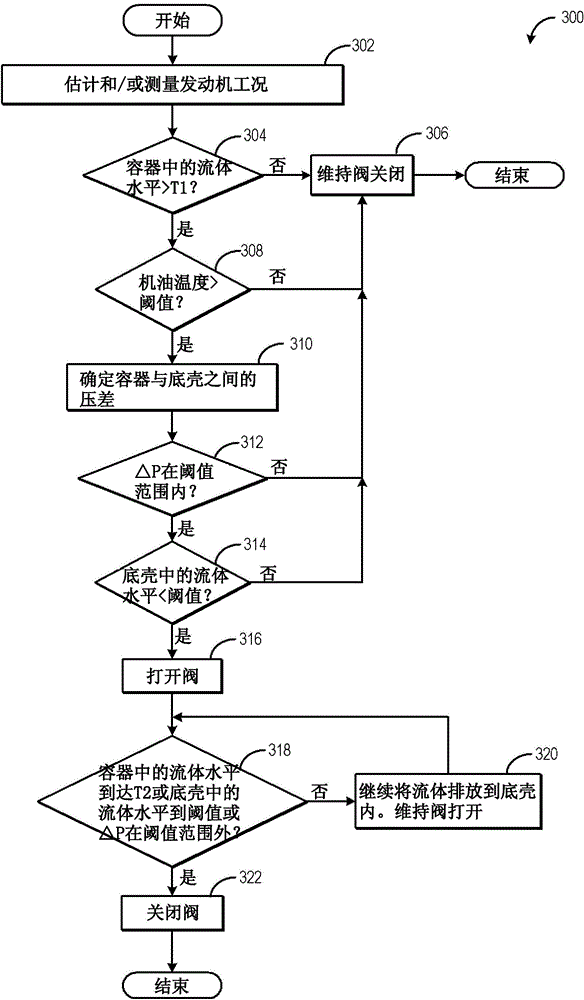

[0022] The following descriptions relate to methods for draining condensate from the charge air cooler (CAC) and introducing condensate into an engine system such as Figure 1-2 Systems and methods for at least one of forced crankcase ventilation flow and an engine oil sump for the engine system shown in . Liquid condensate can be drained into a liquid storage container where some of the liquid can evaporate into water vapor. Water vapor can leave the liquid storage container and enter the forced crankcase ventilation flow. Liquid condensate stored in a container can be drained into the engine sump for vaporization and removal. A drain valve in the fluid storage container controls the flow of liquid condensate into the engine oil sump. exist image 3 An example method of adjusting a drain valve in response to a fluid storage container and engine oil sump condition is described at . exist Figure 4 Example bleed valve adjustments in response to these conditions are shown at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com