Vaporizing burner

A burner and evaporative technology, applied in the direction of burner, combustion type, combustion method, etc., can solve the problems of fuel retention, increase in manufacturing cost, increase in number of parts, etc., and achieve ignition, combustion, and stabilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 》

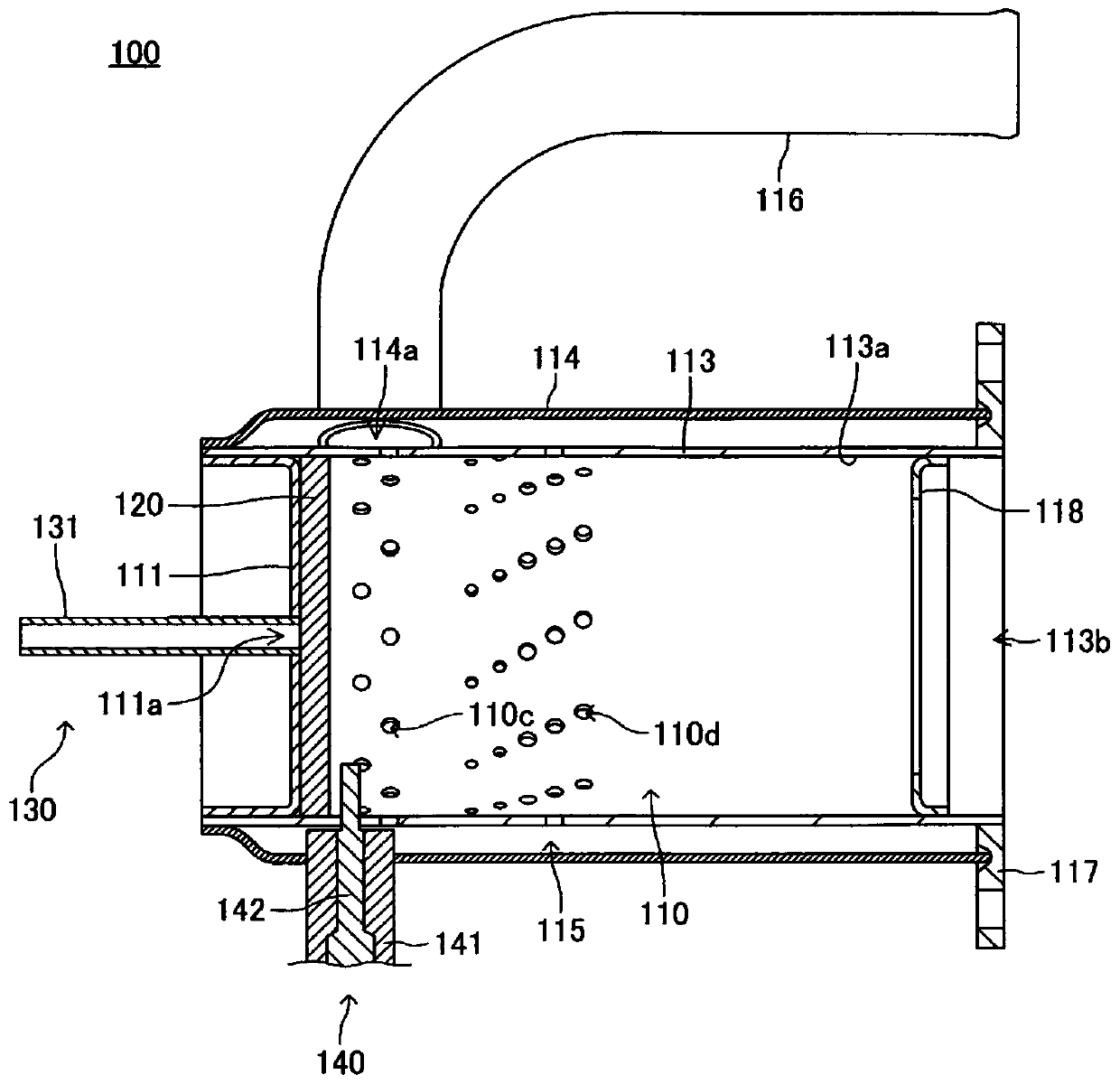

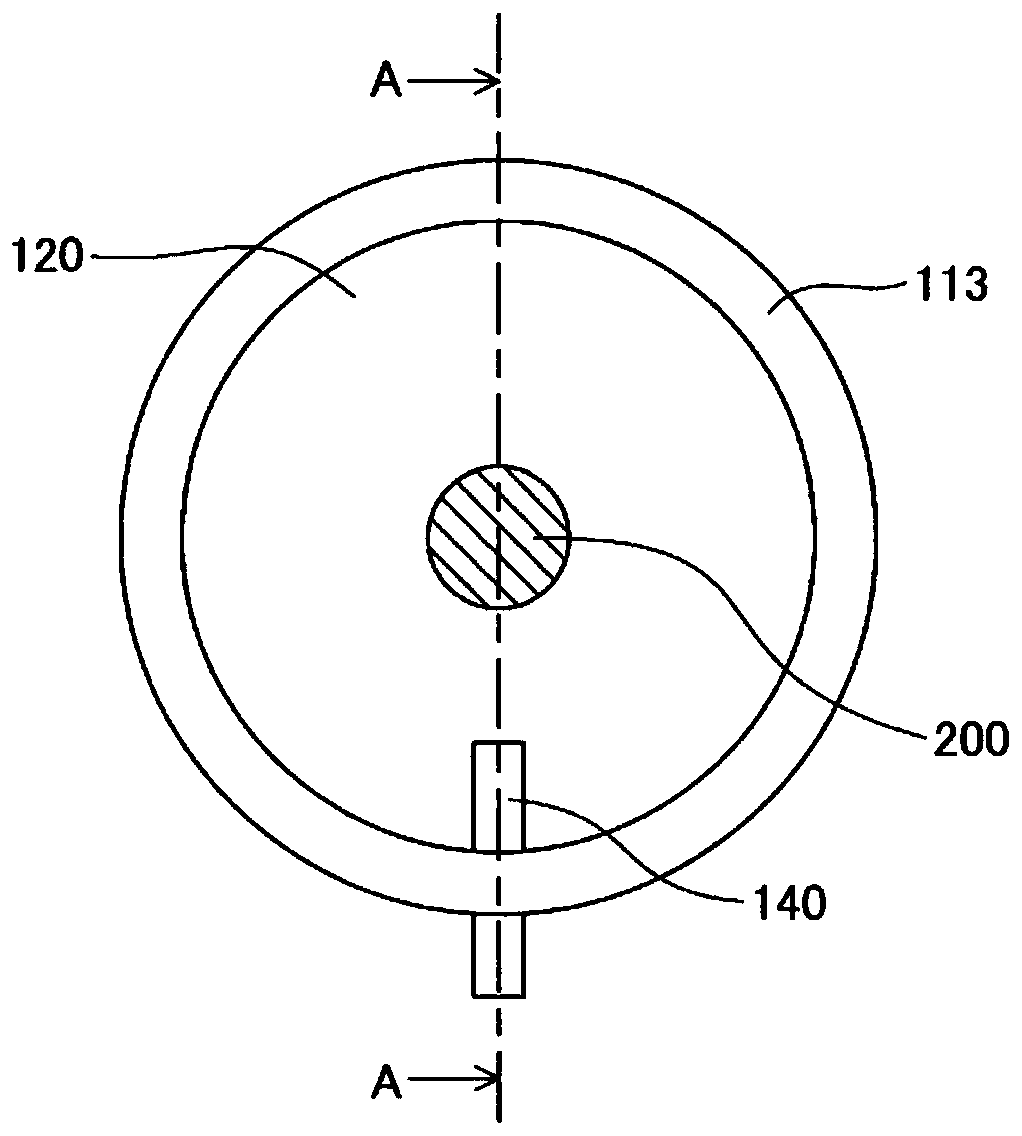

[0057] Hereinafter, an example of the configuration of the evaporative burner (hereinafter, may be referred to as "the first burner") according to the first embodiment of the present invention will be described in more detail with reference to the drawings.

[0058]

[0059] figure 1 It is a schematic cross-sectional view of the first combustor cut along a plane including the axis of the inner casing that defines the combustion chamber. In the following description, the upper side in the vertical direction ( figure 1 The upper side of the sheet) is referred to as "upper", and the opposite side, that is, the lower side, is referred to as "lower". And, towards figure 1 In the paper of , the left side (the impregnated member side) is referred to as the "upstream side", and the opposite side, that is, the right side is referred to as the "downstream side".

[0060] The first burner is an evaporative burner including a combustion chamber, an impregnated member, a fuel supply u...

no. 2 approach 》

[0125] Hereinafter, an example of the configuration of an evaporative burner (hereinafter, may be referred to as a "second burner") according to a second embodiment of the present invention will be described in more detail with reference to the drawings.

[0126]

[0127] The basic composition of the second burner is the same as the reference except for the points explained below. figure 1 The above described first burner 100 is the same. Therefore, description of the basic configuration of the second burner is omitted here.

[0128]

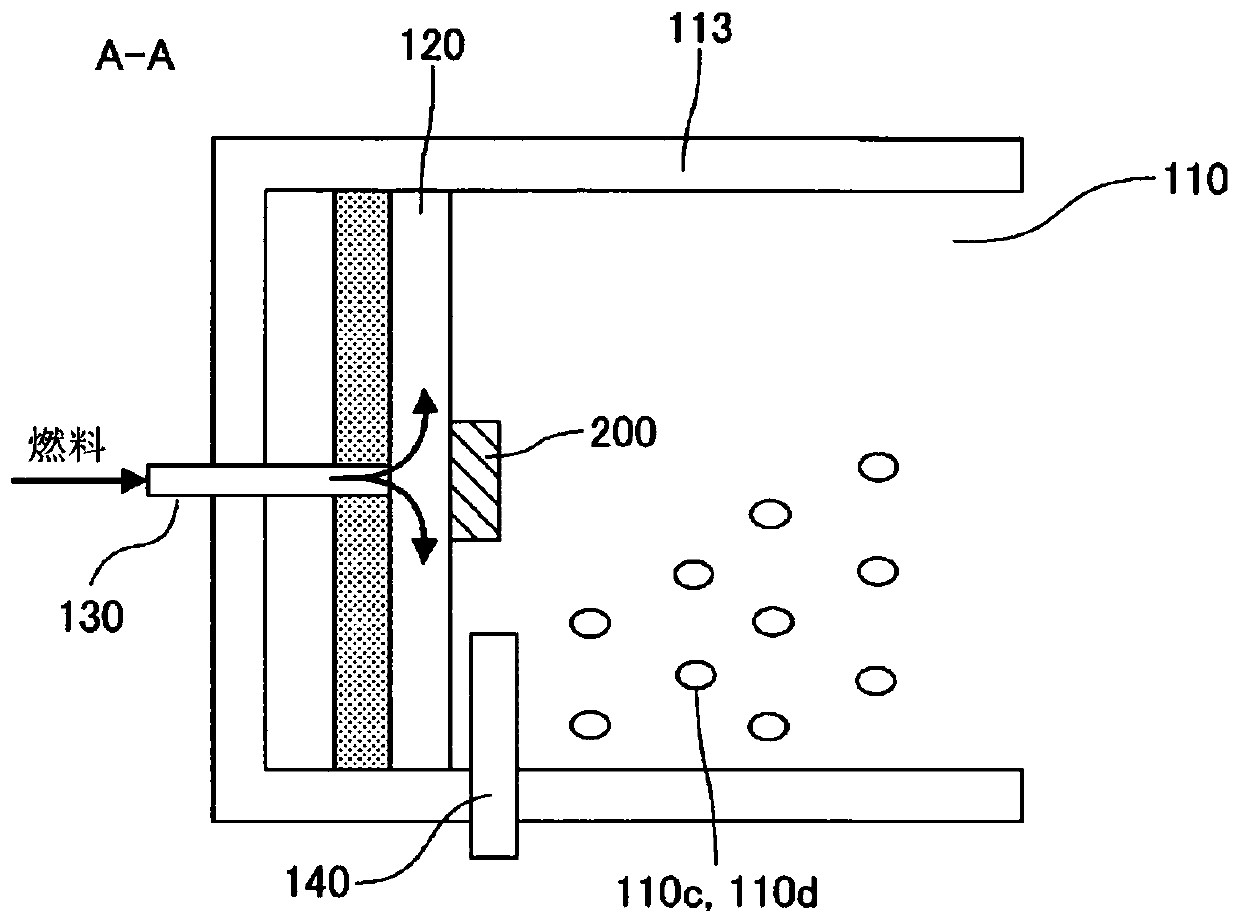

[0129] In the description of the first burner 100, as described above, the seepage preventing member 200 included in the burner of the present invention may be entirely embedded in the impregnated member, or may be entirely buried. It may be arranged outside the impregnated member, or part of it may be buried inside the impregnated member and the other part may protrude from the surface of the impregnated member.

[0130] The anti-seepage ...

no. 3 approach 》

[0135] Hereinafter, an example of the configuration of an evaporative burner (hereinafter, may be referred to as a "third burner") according to a third embodiment of the present invention will be described in more detail with reference to the drawings.

[0136]

[0137] The basic configuration of the third burner is the same as that of the above-mentioned first burner 100 and the second burner except that a partition member is further provided. Therefore, the structure of the third combustor will be described below focusing on the partition member. Thus, in Figure 10 in, with figure 1 Similarly, although the seepage prevention member 200 provided in the third burner 103 is omitted, the third burner 103 can have the seepage prevention member 200 and the rear burner that can be provided in the first burner 100 and the second burner described above. Various seepage prevention members 200 represented by the seepage prevention member 200 that can be provided in the modified ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com