Systems and methods for LP-EGR delivery in a variable displacement engine

A technology of LP-EGR and engine, which is applied in the direction of combustion engine, engine control, machine/engine, etc., and can solve the problems of increasing combustion instability and misfire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

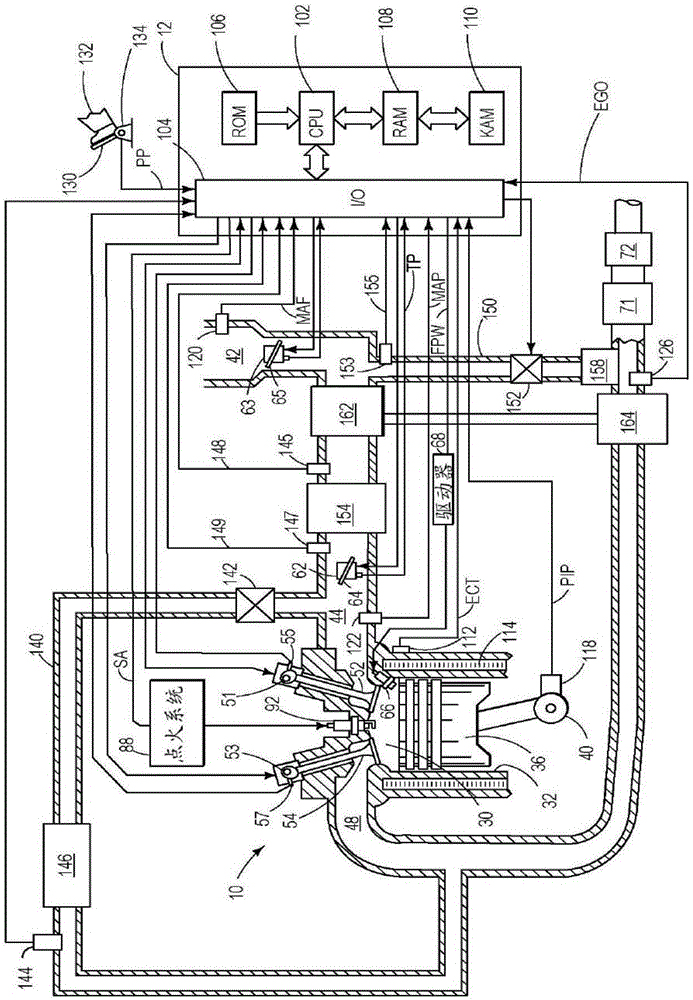

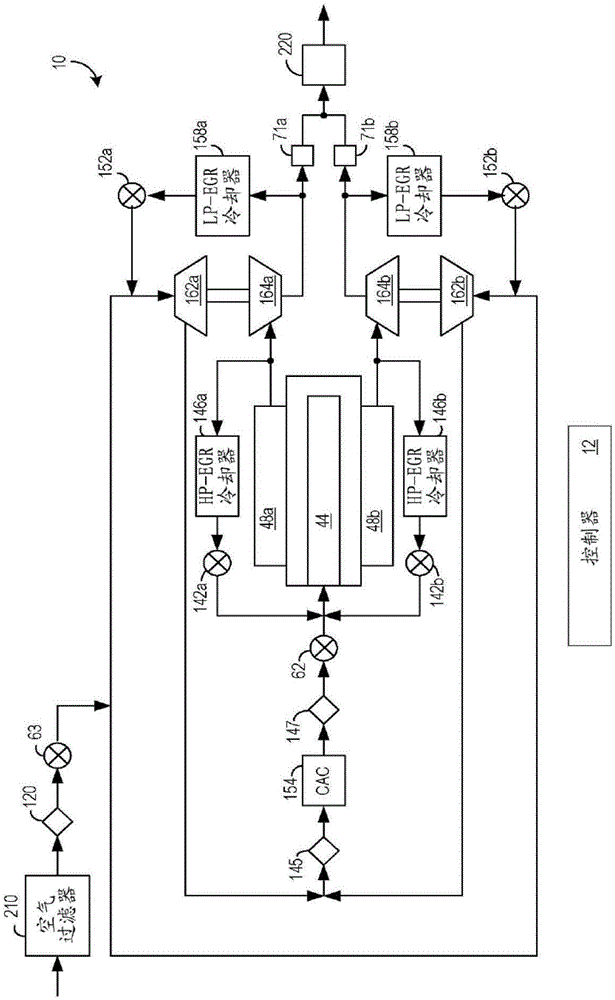

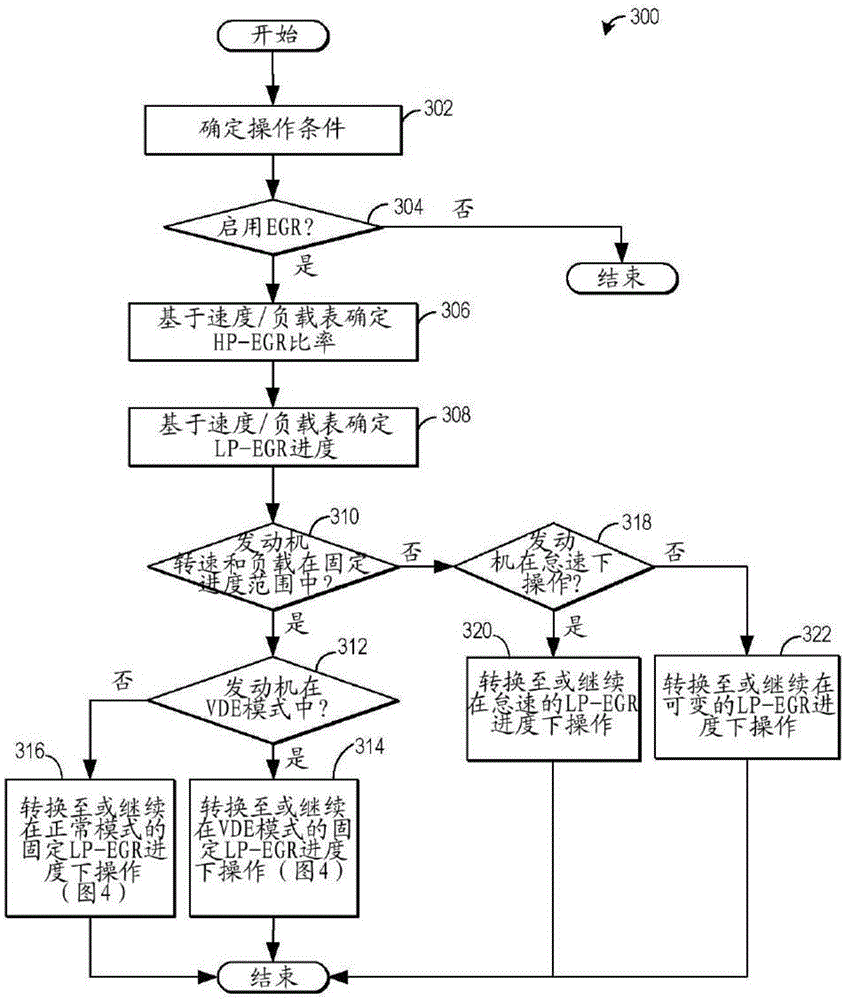

[0017] The present description relates to an EGR system connected to a turbocharged variable displacement engine in a motor vehicle. In one non-limiting example, a VDE engine may be configured to figure 1 A portion of an engine system shown in , wherein the engine includes at least one cylinder, a control system, a turbocharger, an exhaust gas recirculation system, and other components. The engine is also configured to have as in figure 2 Multiple cylinder banks shown in . The engine controller may be configured to execute control programs such as Figure 3 to Figure 4 Exemplary routine) to adjust LP based on the minimum cylinder load requirement of the engine when the engine transitions between operation with all cylinders enabled (non-VDE mode) and operation with one or more cylinders deactivated (VDE mode) - EGR schedule (schedule). Different EGR schedules may be selected based on engine speed load maps, such as the speed load maps of FIGS. 5A and 5B . refer to Imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com