chain drive mechanism

A transmission mechanism and chain-type technology, applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of excessively increased frictional resistance, increased contact area, large load, etc., to reduce contact frictional resistance and improve smoothness sex, avoiding the effect of smooth sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

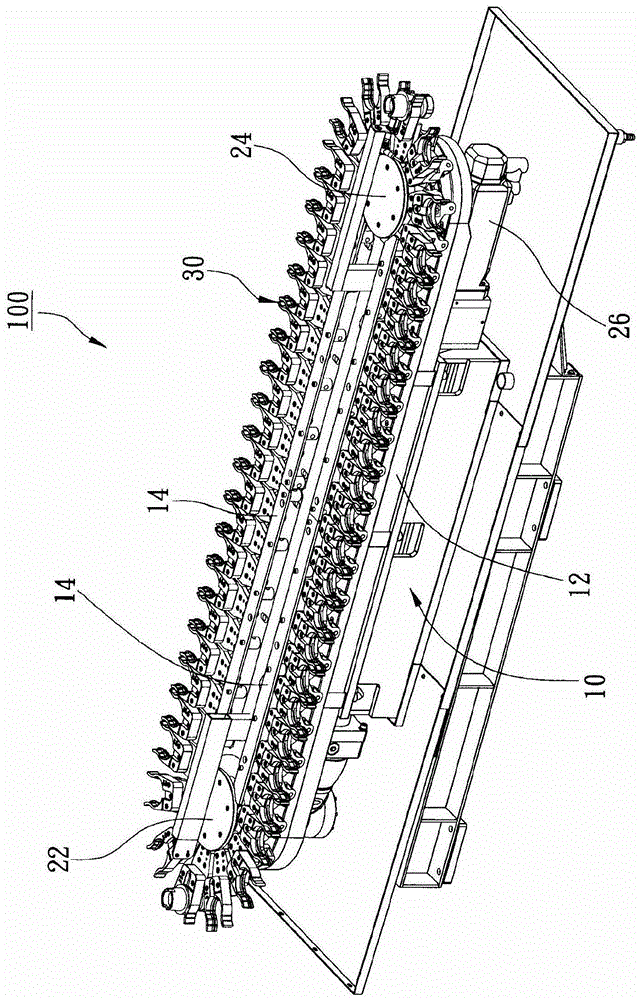

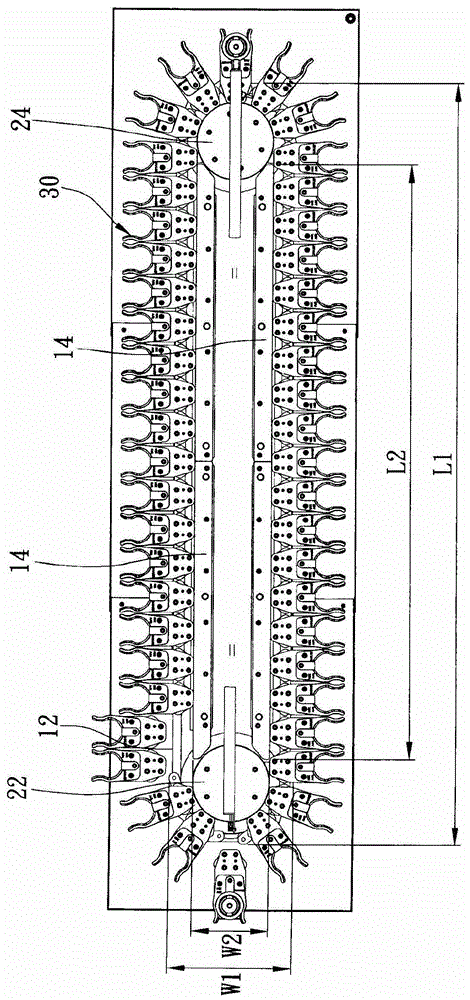

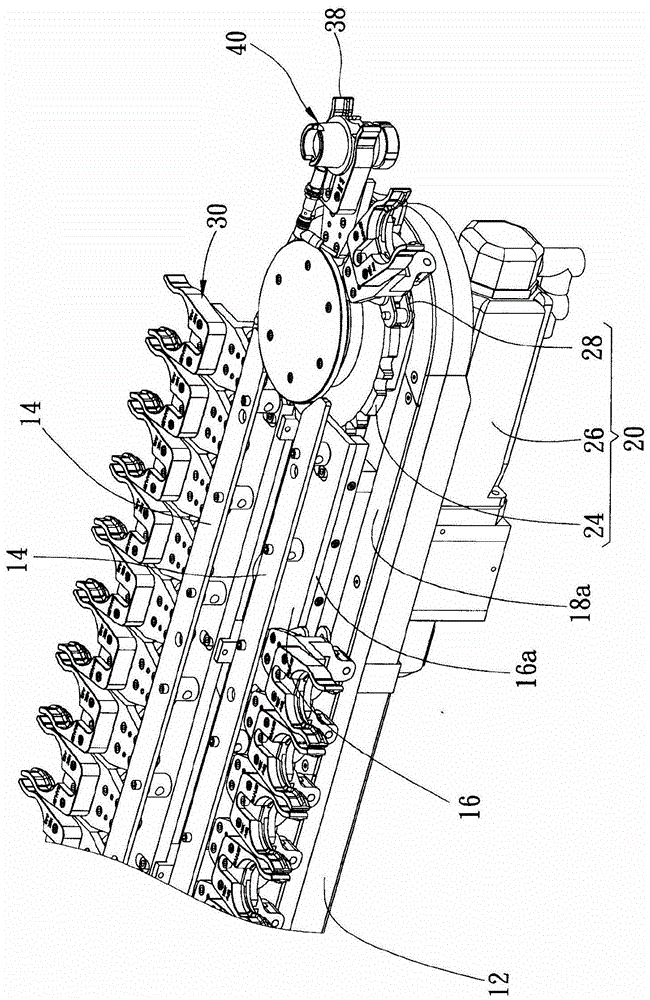

[0036] The chain transmission mechanism provided by the present invention includes a machine table, a transmission unit and a plurality of moving units. Wherein the machine table has a track, and the track defines a first constraint surface and a second constraint surface; the transmission unit has a chain looped in the track of the machine table, and the chain can be driven to follow the track rotation; the moving units are arranged along the track of the machine table, and move synchronously with the rotation of the chain, each of the moving units has a first rolling element and a second rolling element, wherein the first rolling element contacts the The first constraining surface does not contact the second constraining surface, and the second rolling element contacts the second constraining surface but does not contact the first constraining surface.

[0037] Therefore, the rolling contact is used to reduce the frictional resistance, thereby improving the smooth operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com