Modular combination burner

A combined burner and modular technology, which is applied in the direction of burner, gas fuel burner, combustion method, etc., can solve the problems of inconvenient power change and low heat gain rate, and achieve bottom inventory reduction, capital occupation, and simple processing technology , The effect of fully and evenly mixed gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

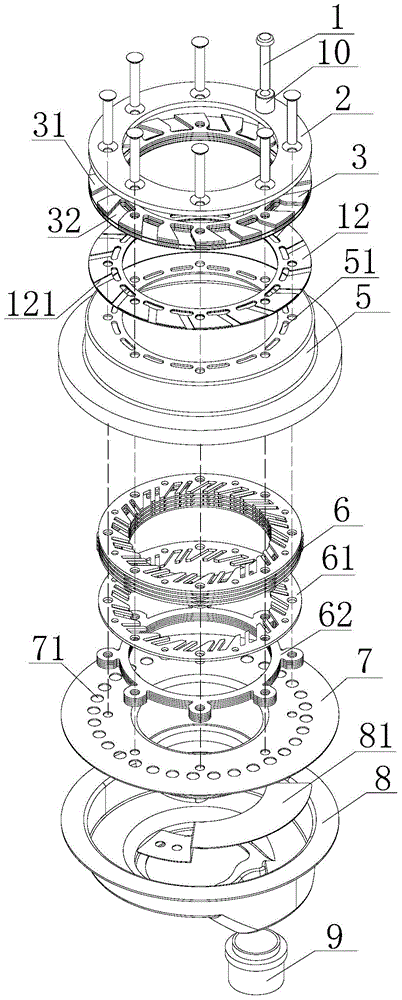

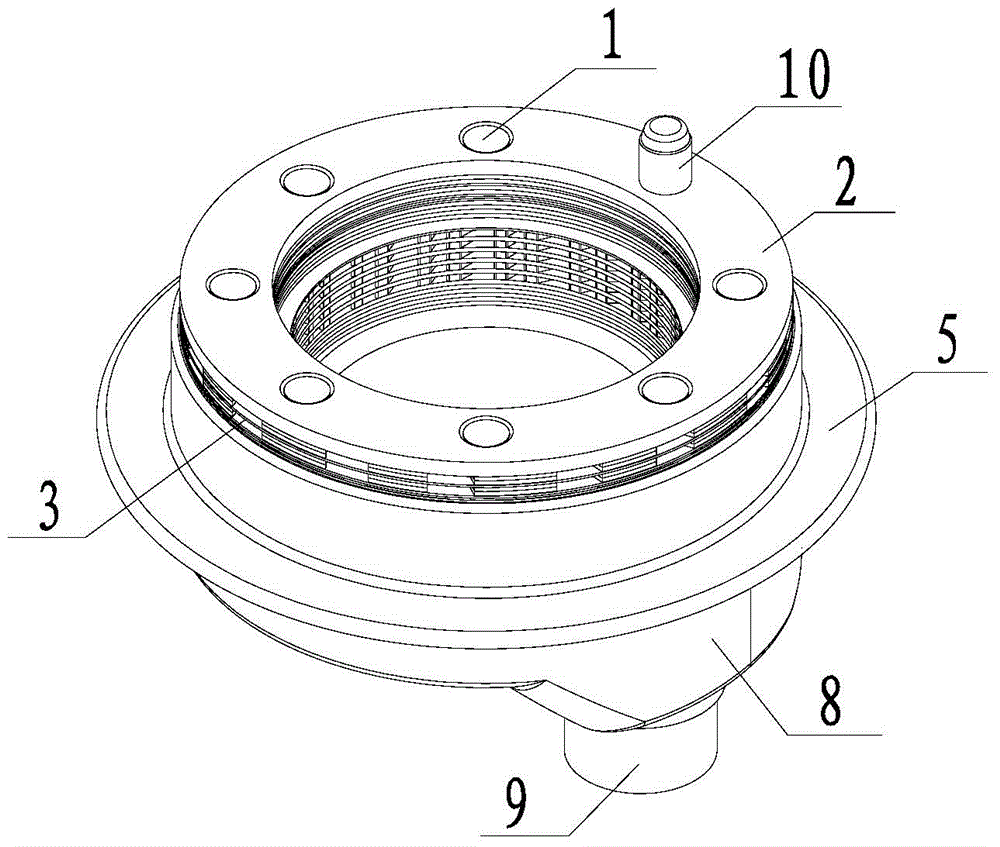

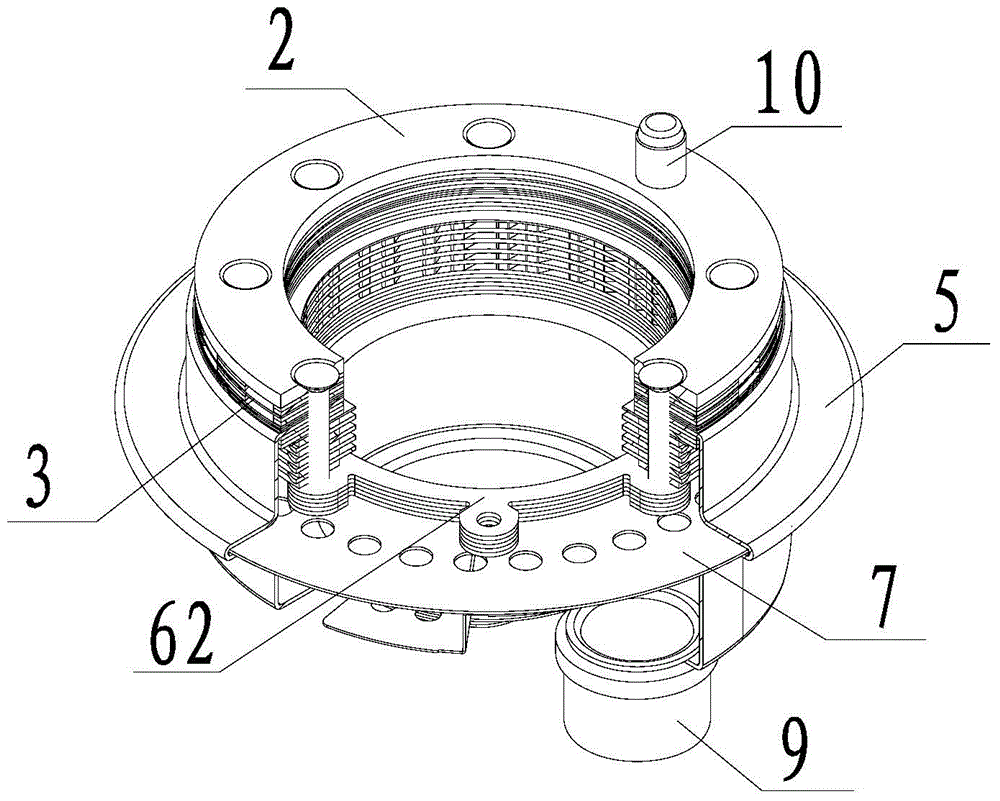

[0029] Referring to the accompanying drawings, for the modular combined burner, the upper casing 5 is connected to the lower casing 8, and a partition 7 is provided between the upper casing 5 and the lower casing 8, and the inner cavity of the upper casing and the inner cavity of the lower casing pass through The first communication hole 71 provided on the partition 7 communicates; the lower housing 8 communicates with the air intake seat 9;

[0030] The inner flame ring 6 is set in the inner cavity of the upper casing, and the inner flame ring 6 and the upper casing 5 enclose the gas distribution chamber 4; the inner flame ring 6 includes an inner fire ring 61 And the inner flame baffle ring 62, the first groove 611 extending from the inner edge to the outer edge direction is opened on the inner fire outlet ring 61, and the outer diameter of the inner flame baffle ring 62 is smaller than the first groove The outer diameter at 611, the inner flame baffle ring 62 and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com