On-site sensor fault detection method based on oil-extraction production data

A technology of sensor faults and detection methods, applied in electrical testing/monitoring, etc., can solve problems such as unsatisfactory fault diagnosis results of sensor groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

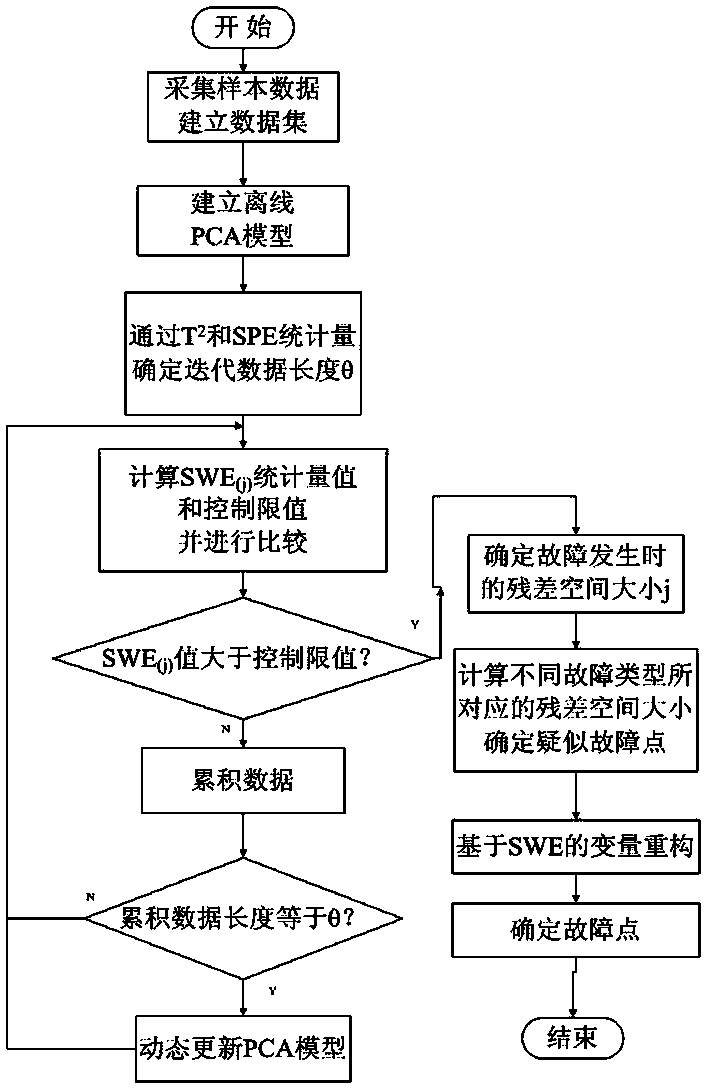

[0066] The specific embodiment: the present invention will be further described below in conjunction with accompanying drawing:

[0067] The invention provides a field sensor fault detection method based on oil production data, which is characterized in that: the steps of the method are as follows:

[0068] 1) Under normal production conditions, that is, when the working status of each sensor is normal, collect sample data and establish a data set;

[0069] 2) Establish an offline PCA model, and measure the data X 0 for each column of X 0 (i) Standardize, through the formula calculated control limit value;

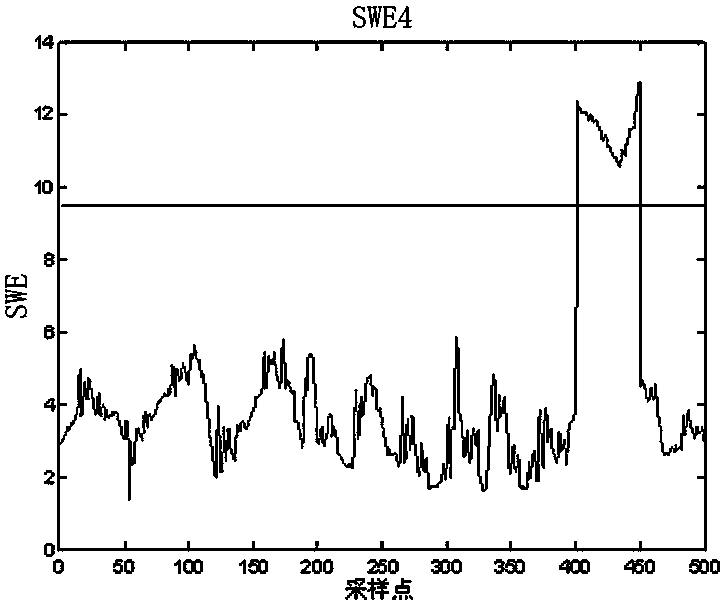

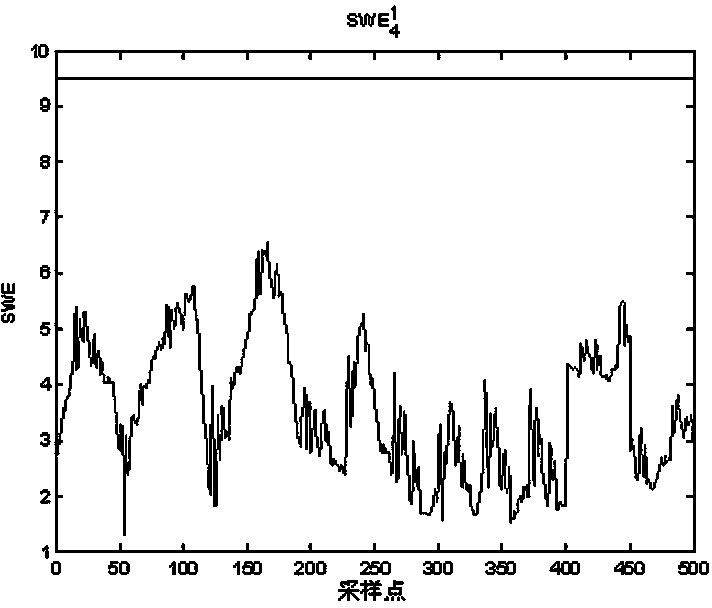

[0070] 3) Implement online monitoring and calculate the SWE of online data (j) statistic value, and with To compare, if Then the detected equipment is running normally, go to step 4); if If there is a fault detected, go to step 5);

[0071] 4) Model dynamic iterative update:

[0072] The present invention sets the data between the control limits of 0.90≤α≤0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com