Capacitive touch screen of post double-layer single-sided metal electrode array

A capacitive touch screen and metal electrode technology, which is applied in the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve problems such as affecting visual effects and moiré patterns, and achieve simple production process and high yield. , The effect of improving light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

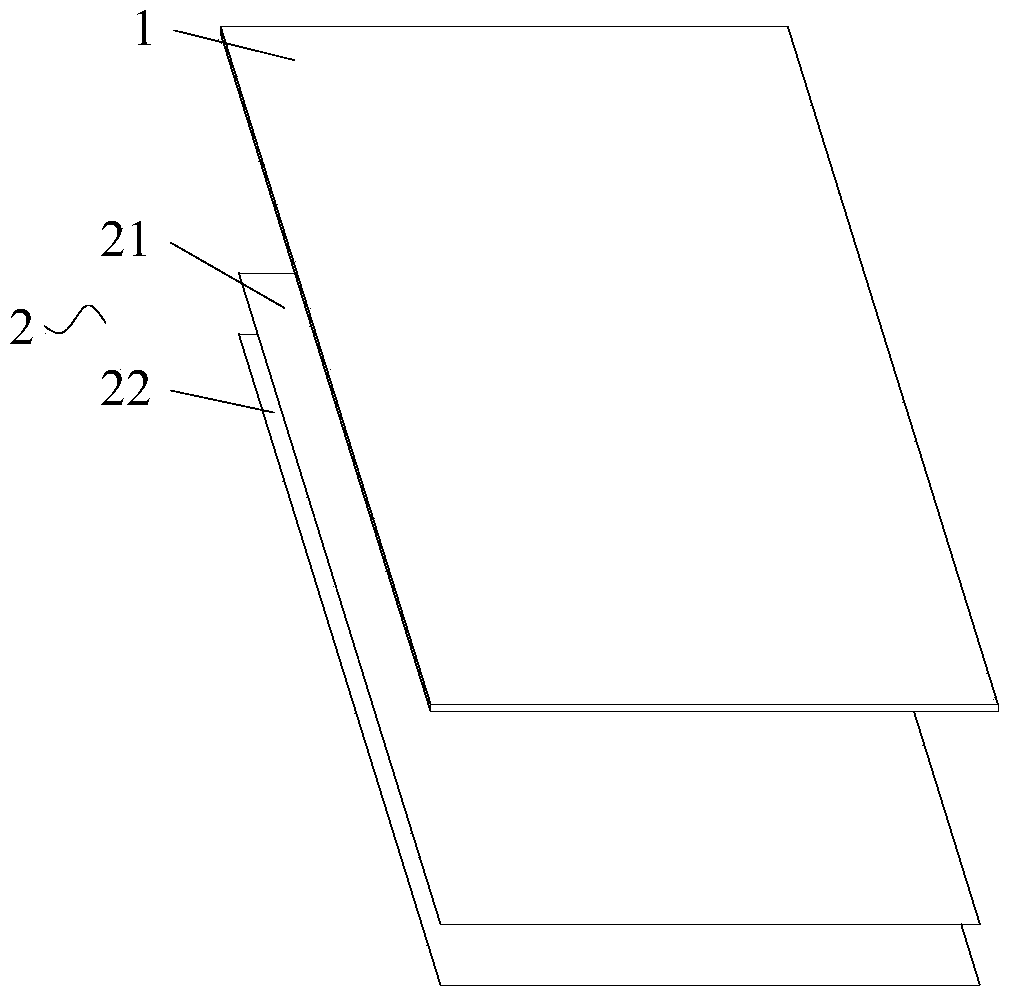

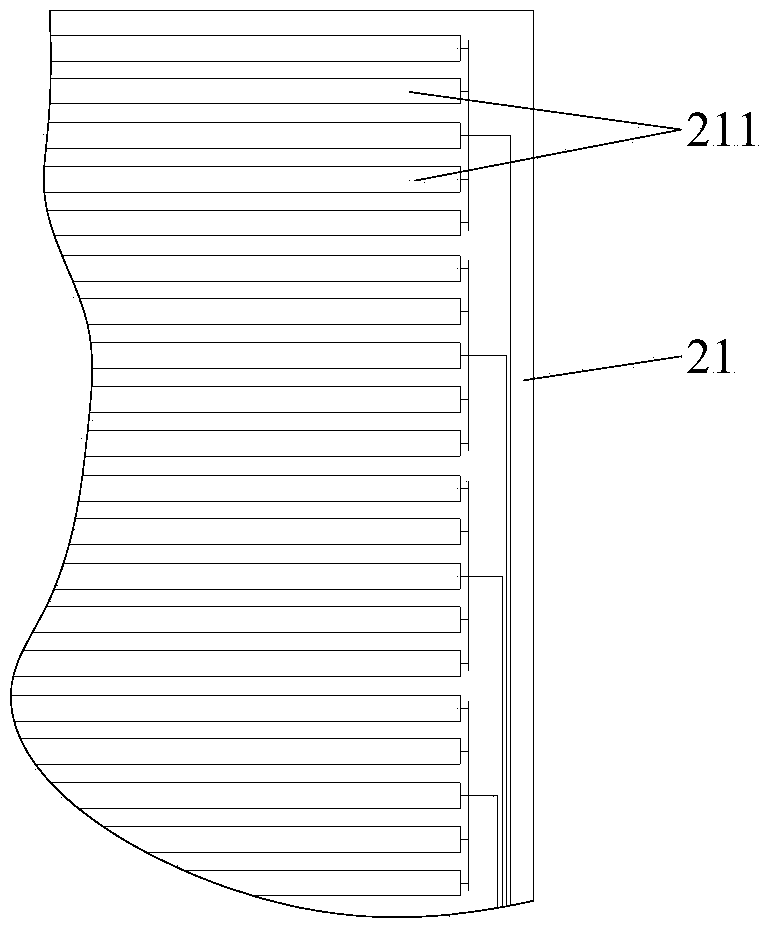

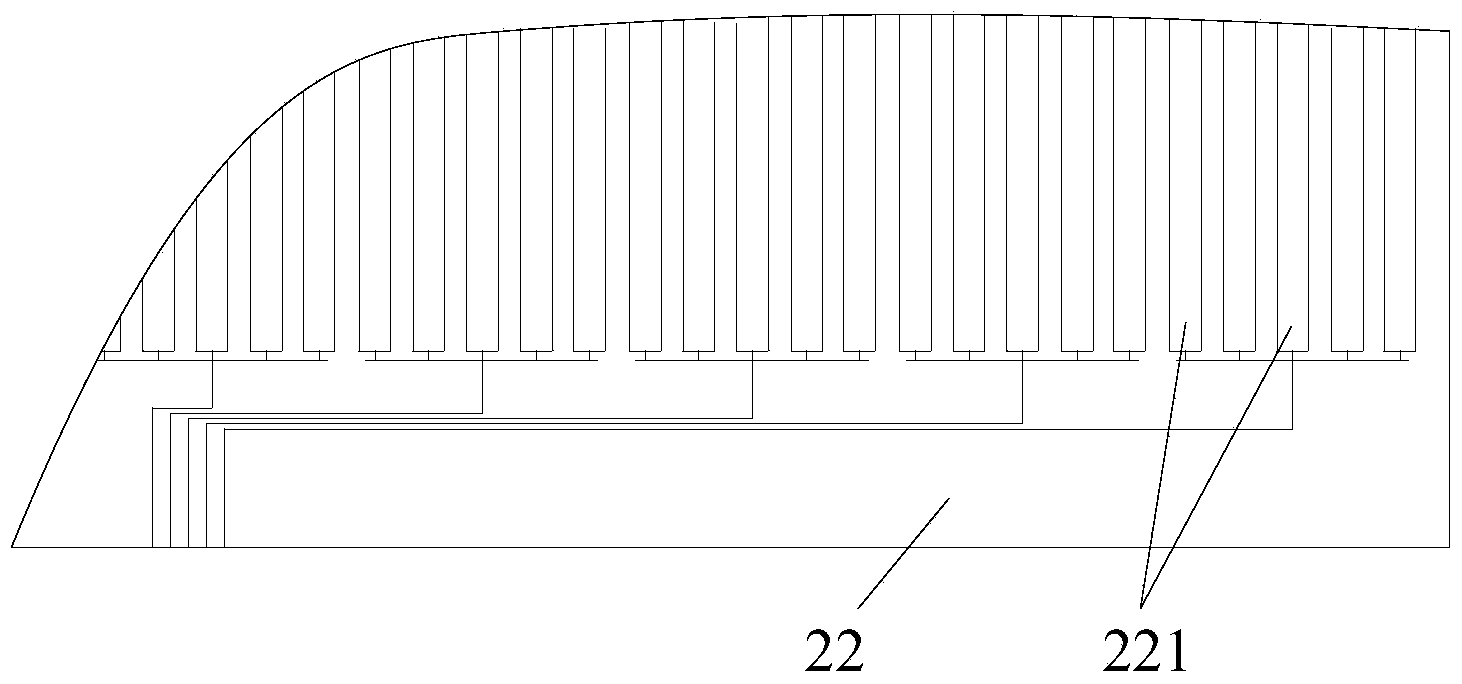

[0023] Such as figure 1 , figure 2 or image 3 As shown, the rear-mounted double-layer single-sided metal electrode array capacitive touch screen of the present invention includes a display screen 1, and a conductive film 2 is attached to the back of the display screen 1, and the conductive film 2 includes two transparent substrates 21 , 22, two transparent substrates 21, 22 are connected into one body through an optical adhesive layer, wherein one transparent substrate 21 is provided with a horizontal metal electrode array, and the other transparent substrate 22 is provided with a vertical metal electrode array; The horizontal metal electrode array is composed of a plurality of parallel and linear horizontal metal conductive strips 211, and the vertical metal electrode array is composed of a plurality of parallel and linear vertical metal conductive strips 221; Both the conductive strips 211 and the vertical metal conductive strips 221 are formed by etching or printing; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com