Method for predicting vibration performance of movable guide vane of water turbine

A technology of movable guide vanes and vibration characteristics, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as ignoring the influence of guide vanes, reducing simulation accuracy, and problem complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

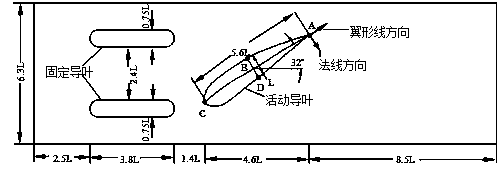

[0065] Embodiment 1: The following takes the fluid-solid coupling calculation model of movable guide vanes in the water guide mechanism of a certain type of Francis turbine as an example. For specific calculation objects, see image 3 , the present invention will be described in further detail.

[0066] Step 1: Calculation of the initial value of the steady-state flow field

[0067] Set the boundary conditions of the flow field, the left side is the velocity inlet boundary, the velocity =0.816m / s, the right side is the free flow, and the rest of the boundary adopts solid wall surface, the steady-state calculation of the surrounding flow field under the initial configuration of the guide vane is carried out, and the stress of the fluid side node of the coupling interface is extracted at the same time;

[0068] Step 2: Synchronous Bidirectional Iteration

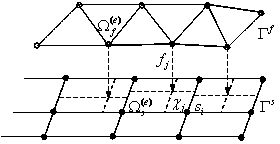

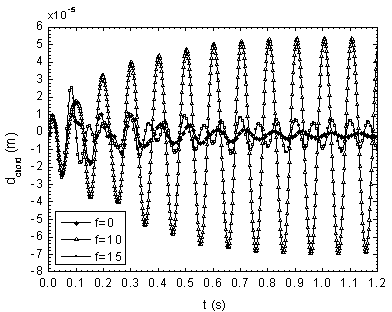

[0069] By calling the synchronous bidirectional iteration module, the entire fluid-structure interaction system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com