A test device and test method for the mechanical properties of the interface between marine energy soil and structure containing natural gas hydrate

A technology of mechanical properties and testing devices, applied in the direction of using stable shear force to test material strength, using stable tension/pressure to test material strength, and preparation of test samples, etc., can solve the problem of low shear strength, formation The strength and bearing capacity are reduced, and the volume change of the test soil sample is not considered, so as to avoid the test error and achieve the effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

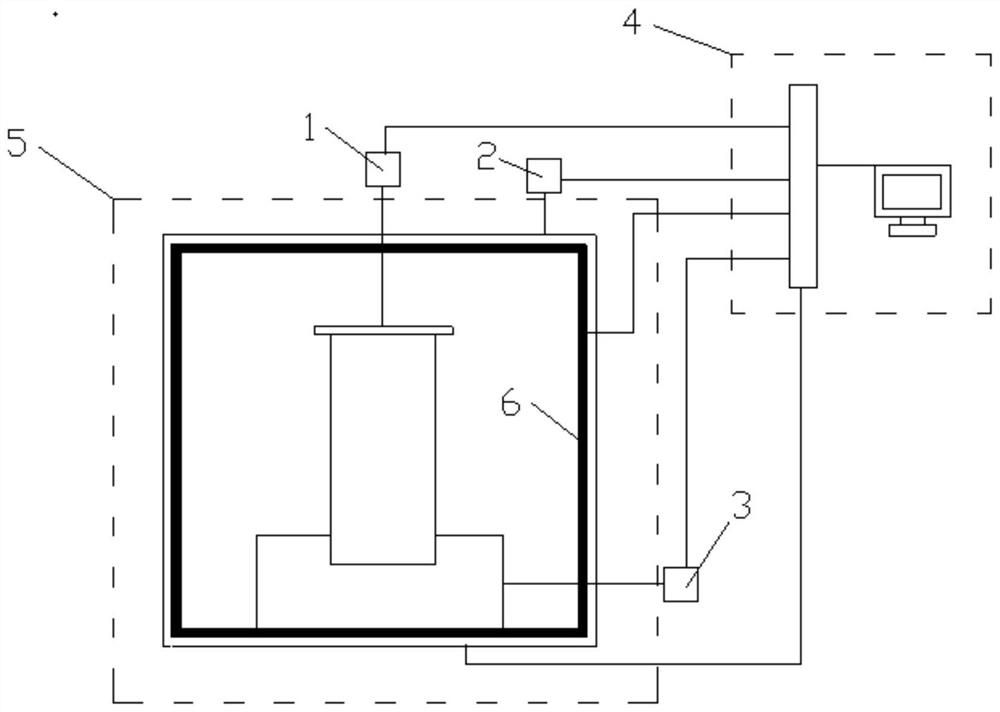

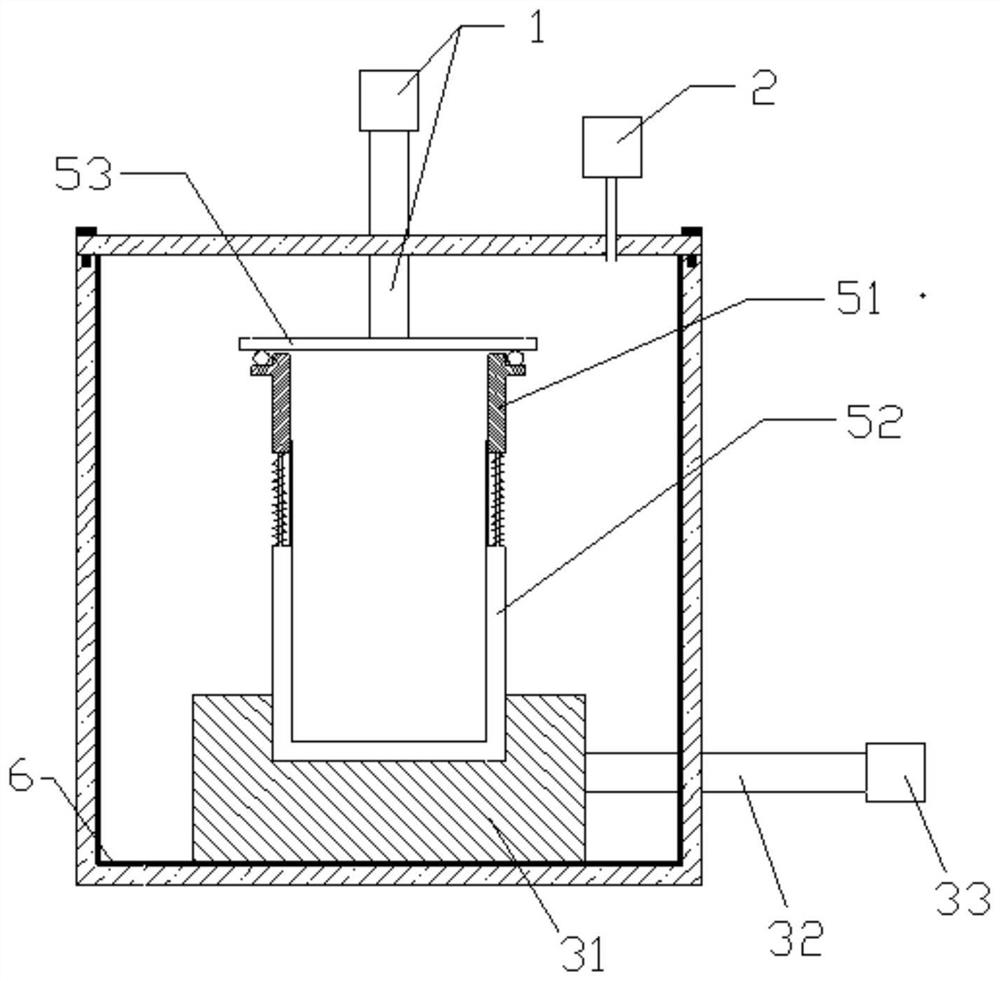

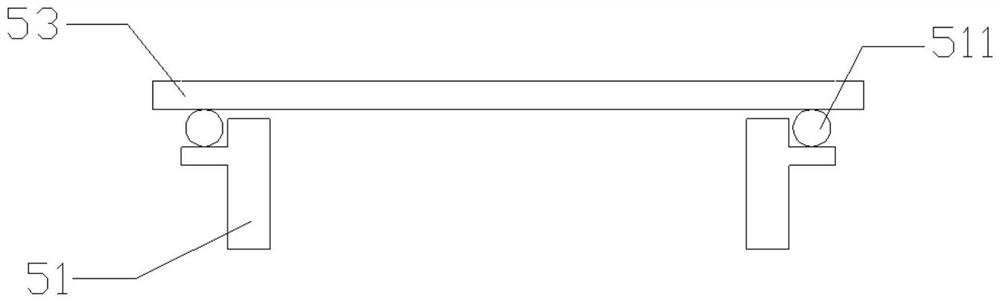

[0018] like figure 1 As shown in the figure, the test device for the mechanical properties of the interface between marine energy soil and structure containing natural gas hydrate includes: axial loader 1, air pressure tank 2, side loading shear 3, data transmission and acquisition processor 4, sealing pressure Chamber 5, temperature refrigerator 6. Among them: the side loading shear 3, the axial loader 1 and the air pressure tank 2 are respectively connected with the sealed pressure chamber 5 to realize the application of gas pressure and the loading of different stress modes and different stress paths; the temperature refrigerator 6 will seal the pressure chamber The internal space is seamlessly surrounded to realize the control of the experimental temperature; the data transmission and acquisition processor 4 is respectively connected with the sealed pressure chamber 5, the side loading shear 3, the axial loader 1, the temperature refrigerator 6, and the air pressure tank 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com