Stroke automatic adjusting device on motor stator needle type wire winding machine

An automatic adjustment device and motor stator technology, applied in electromechanical devices, electric components, manufacturing motor generators, etc., can solve problems such as difficult stroke adjustment, affecting winding quality, and high labor intensity, so as to achieve simple stroke adjustment and ensure winding The effect of low thread quality and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

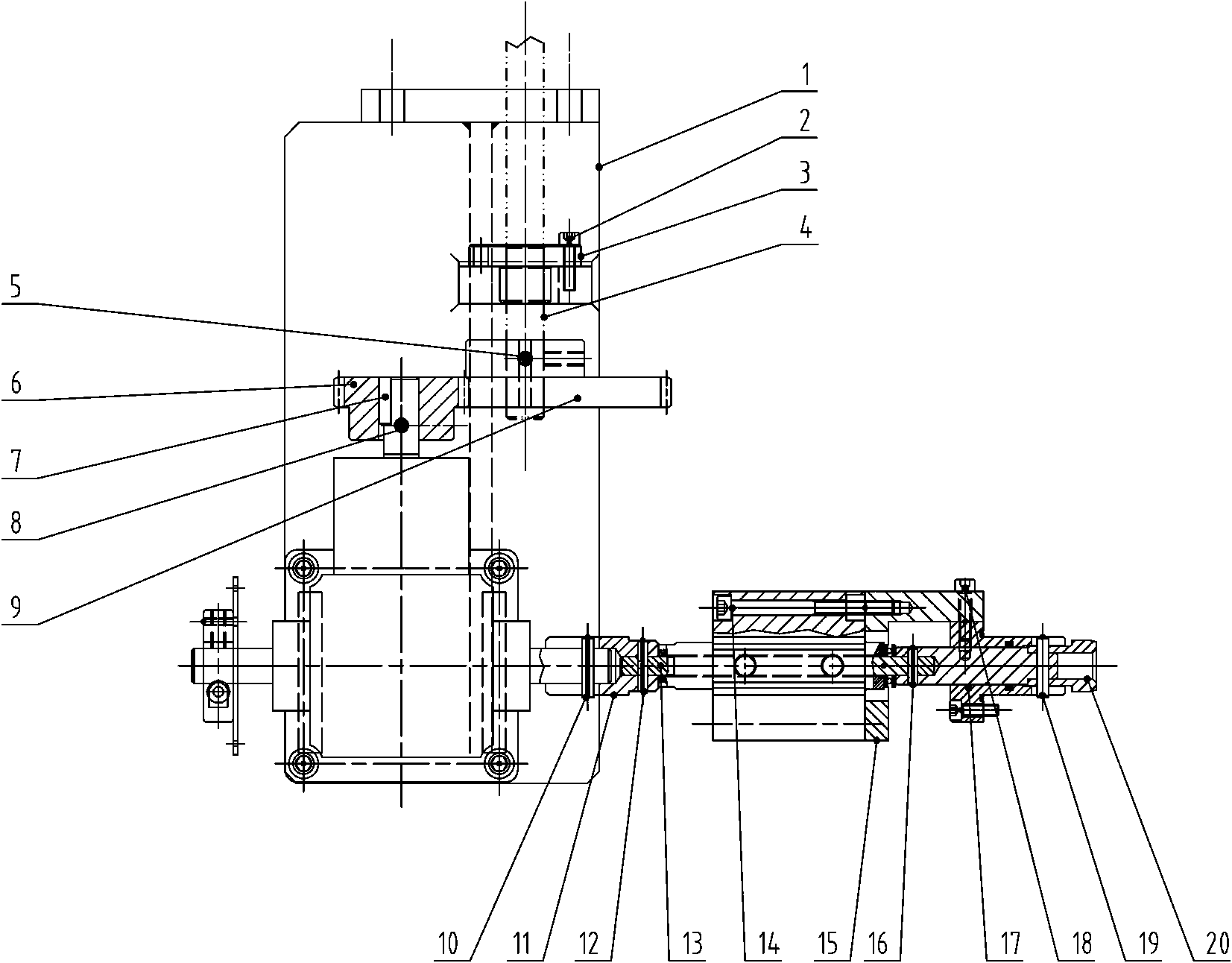

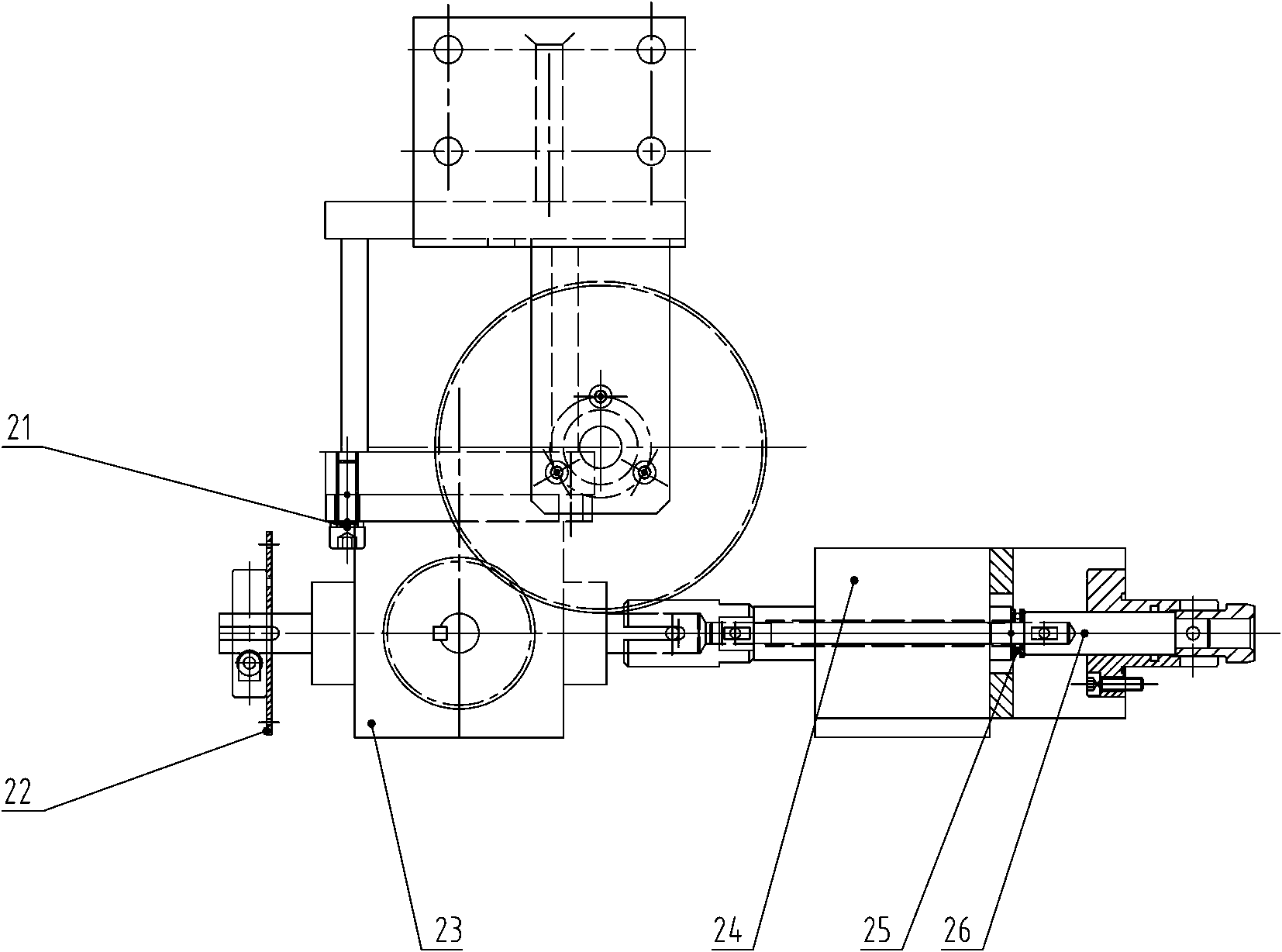

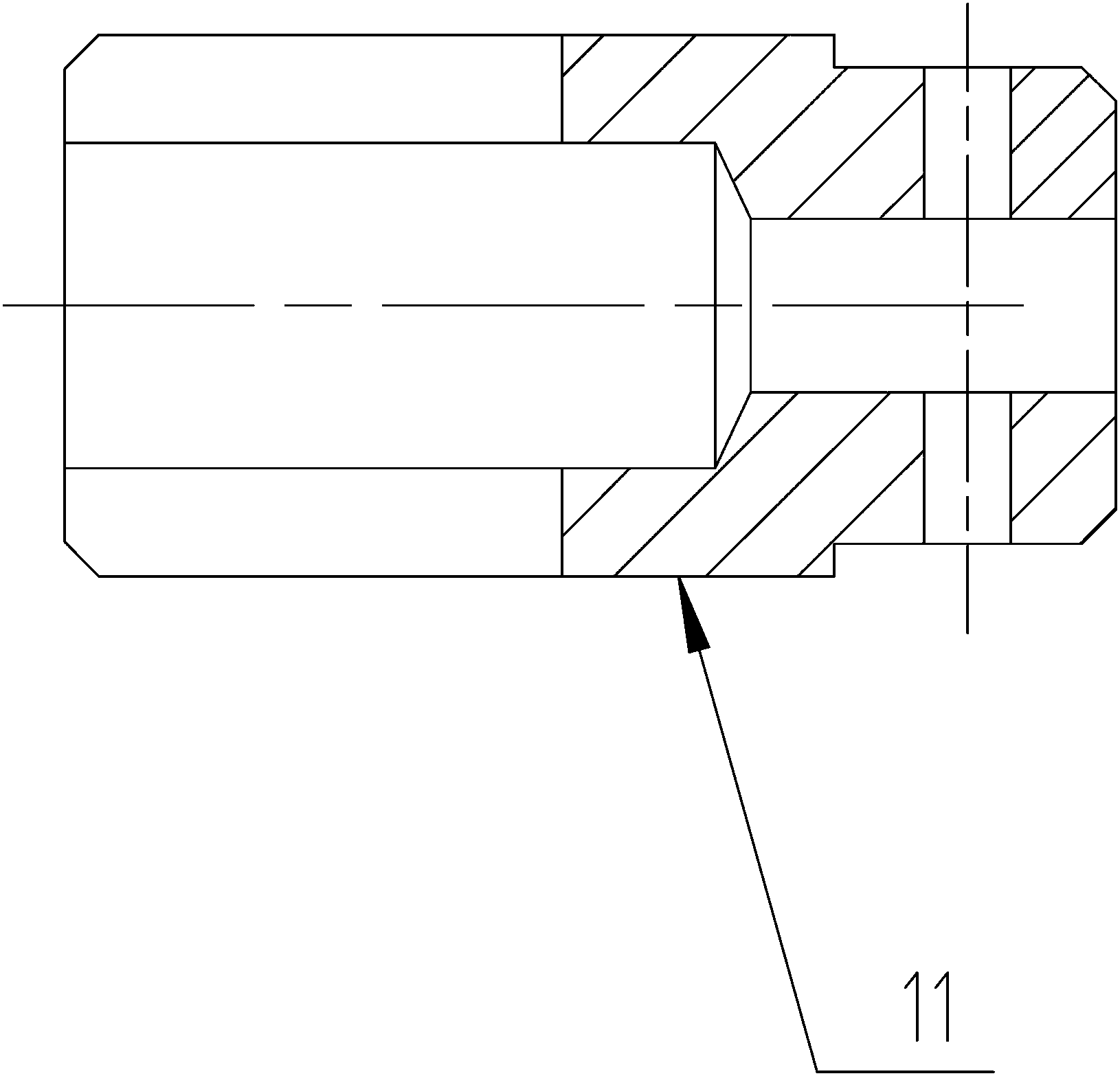

[0011] Reference attached Figure 1 to Figure 6 , an automatic stroke adjustment device on a motor stator needle winding machine, characterized in that: on the frame body of the transmission mechanism 1, the screw 2 is fixedly connected with the guide seat 3, the drive shaft 4 is set in the guide seat 3, and the large gear 9 The screw 5 is fixedly connected with the drive shaft 4, the pinion 6 is fixed on one shaft end of the reduction box 23 through the key 7 and the screw 8, and meshes with the large gear 9, and the reduction box 23 is fixed with the transmission frame body 1 through the screw 21. Coupled, the reduction box 23 is fixed with a counting disc 22 at one shaft end. The other shaft end of the reduction box 23 is slidingly connected with the coupling 11 through the elastic cylindrical pin 10, the coupling 11 is fixedly connected with the adjusting rod 13 through the elastic cylindrical pin 12, the adjusting rod 13 passes through the hollow piston rod of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com